MOTOR VEHICLES (see 18.914). Improvements in design between 1910 and 1920 made the passenger motor-car a more reliable, more comfortable and, allowing for changed conditions, more economical vehicle; they also rendered it more attractive to the eye. During the same period the use of cars greatly increased, particularly in the United States, where registration figures showed that in the state of Iowa there was on July i 1920 one car to every 5-49 of the population, while for the whole country the proportion was one to every 13-52 people. To a certain extent the World War was responsible for the fact that in the use of motor-cars Europe did not keep pace with the United States. In France, Belgium, Germany and Austria the manufacture of cars for sale to the public ceased absolutely upon the opening of hostilities, and was not resumed until after the Armistice; in Great Britain and Italy, too, motor-car factories were restricted to work for the armies, practically throughout the war. In the United States, on the other hand, not only was there no interruption in production for private account, but the war- born wave of prosperity of 1915-6 increased sales over what they would have been under normal conditions. After the United States entered the war many motor-car plants were turned over to the production of aero-engines and munitions, and had the war continued after Jan. i 1919 the manufacture of passenger cars for other than military purposes would have ceased in America as completely as in Europe.

The chief reasons, however, for the preeminence of the United States in the use of motor-cars had nothing to do with the World War. In the first place America is a land of magnificent distances; in many sections towns and cities are far apart, and long trips must often be made over the public roads, for which purpose horse vehicles are quite unsatisfactory. Secondly, petrol (in the United States called gasoline), the fuel commonly used for motor vehicles, is a native product, comparatively cheap and plentiful. Thirdly, per capita wealth is greater than in most countries and well distributed. Not all conditions were favourable to the in- troduction of motor-cars however. Whereas the industrial coun- tries of Europe had magnificent systems of hard-surfaced roads, such roads were practically non-existent in the United States at the beginning of the motor era; but while a handicap, this did not prove a serious obstacle. In the early years of motor-car development the private passenger car was generally regarded as a means of pleasure, and in Europe this remained its chief func- tion. But in the United States and Canada (which comes next after the United States in respect to number of cars owned, notwithstanding its comparatively small population) it became a great factor in business life. In New York City, for instance, a very large proportion of the street traffic in 1920 was by motor, and in the main thoroughfares horse vehicles were almost a rarity. On the other hand, such agricultural states as Iowa and Nebraska had relatively more cars than tke industrial states, and the farmers, too, used their cars chiefly for business purposes. As the substitution of the motor-car for the horse came about gradually, it did not greatly impress the general public; neverthe- less it profoundly influenced modern life.

Conditions in Nyack, N.Y., a town of 5,000 inhabitants, 25 m. from New York City, may be cited for illustration. In 1905 Nyack had only one motor-car, owned by a physician ; in 1920 deliveries of all articles of commerce, from the morning newspaper to coal and building material, were made by motor vehicles, with the one excep- tion of goods delivered by the railway express, which still adhered to horse service. The junkman made his rounds in a motor-car. All moving of household goods was effected by motor-van. Motor- buses were the only means of public transit, and in addition to making their regular trips they carried children in the outlying dis- tricts to and from school. The fire department had been " motor- ized." A large proportion of the residents owned private cars, which ' they used for driving to church or to the theatre, for shopping and visiting, as well as for pleasure-driving. On Saturctay afternoons the main business street was so crowded with cars that it was often diffi- cult to draw up to the curb.

In the cities of the United States the once familiar horse-cabs and hansoms had practically disappeared before the motor- propelled taxicab by 1920. There were bus services competing with the tram services, though these had not been developed to the same extent as in the leading European cities. Numerous

bus lines had been established in country districts beyond tram services. About 1915 many owners of private cars began carry- ing passengers in competition with tram lines, their vehicles being known as jitney buses (jitney, a Russian coin about equal in value to five cents, then the common tram fare). These jitneys did much business, especially during the " rush " hours when people go to work and return home, as their passengers avoided the crowding of the street-cars and the annoyance of frequent stops. But after a short time the greatly increased cost of petrol and war conditions rendered the business unprofitable, and little more was heard of jitneys. Many cars of the private type were still offered for hire, but five cents was no longer a sufficient fare, and the drivers usually called their vehicles taxis, though in the smaller towns as a rule they carried no taximeter.

Motor-trucking and the haulage of freight by motor vehicle began to assume importance in the United States only about 1910. This branch of the industry up to then had been more suc- cessful in Great Britain and Germany. Beginning with that year, however, it consistently increased in the United States, where under the stress of war conditions the motor-lorry even entered into competition with the railways. An enormous amount of motor freight traffic grew up over certain routes be- ; tween important industrial cities, as between Detroit, Mich., and Toledo, O., and between Akron and Cleveland, O. One large tire manufacturing company in Akron, O., with cotton mills in Boston, Mass., over 600 m. away, established a fast freight service between these two distant cities by means of motor-trucks on pneumatic tires. Some of this development was evidently due to the abnormal conditions which made railway freight service inadequate during and immediately after the World War. Military operations gave a great impetus to motor- truck development (see MOTOR TRANSPORT, MILITARY). Thou- sands of motor-trucks were employed by the armies on both sides. The Central Powers were greatly handicapped in this respect, as, owing to the blockade, they could get no rubber for tires, and during the latter part of the war their army trucks ran on wood and steel tires. All of the material for the American army in France was transported by motor-trucks from the landing points to the battle-line. In addition to the urgent demand for trucks for military purposes there was also a strong demand for business purposes, owing to the intense industrial activity and to the breakdown of the railways under the war strain.

The substitution of the motor-car for the horse was beneficial in various ways. In the first place the car is much more speedy and more comfortable for transport. With a motor-car a physi- cian, for instance, can extend his practice over a much wider territory; contractors can oversee more thoroughly a number of projects under way at the same time; stores and factories can deliver goods in the country, at distances of 30 m. or more, in their own vehicles, whereas with horses their delivery territory was limited to the city. Stables, always a nuisance and a breed- ing place of disease, have been practically eliminated from cities, and street-cleaning has been rendered much easier. Real estate remote from railways has in many instances considerably appreciated in value as a result of the advent of the motor-car, which rendered it accessible to the city man.

In the foregoing the utilitarian aspect of the motor-car has been specially emphasized. While cars are still being built that can properly be classed as vehicles of sport and luxury, they form a small proportion of the whole production. In New York City an annual show was established for this class of car; it started as the Importers' Salon, but during the World War, when the importation of European cars was hedged about with many difficulties, it gradually changed its character and became a show of high-grade domestic as well as imported cars. At the salon in Nov. 1920 there were exhibited cars selling at upward of $20,000, whereas a serviceable five-passenger car could be bought for as low a price as $550. The luxury cars exhibited at these shows were characterized by high power and high speed, elegant body finish, fine upholstery and superior equipment.

In tracing motor-car development in Europe between 1910 and 1921 it is necessary to distinguish two periods, before

| 1912 | 1916 | 1920 | |

| Alabama | 3,385 | 21,636 | 74,637 |

| Arizona | 1,624 | 12,124 | 34,559 |

| Arkansas | 2,250 | 15,000 | 59,082 |

| California | 88,699 | 232,440 | 568,892 |

| Colorado | 8,950* | 43,296 | 128,951 |

| Connecticut | 24,101 | 61,855 | 119,134 |

| Delaware | 1,732 | 7,102 | 18,300 |

| District of Columbia | 1,732* | 13,118 | 9,712 |

| Florida | 1,749 | 20,718 | 57,000* |

| Georgia | 19,120 | 47,579 | 144,422 |

| Idaho | 2,500* | 12,999 | 50,750 |

| Illinois | 68,073 | 248,429 | 568,759 |

| Indiana | 54,334 | 139,317 | 332,707 |

| Iowa | 47,188 | 198,602 | 437,300 |

| Kansas | 22,000 | 112,122 | 265,396 |

| Kentucky | 5,147 | 31,700 | 112,685 |

| Louisiana | 7,000* | 17,000 | 66,000 |

| Maine | 7,743 | 30,972 | 62,907 |

| Maryland | 10,487 | 44,245 | 105,000* |

| Massachusetts | 50,132 | 136,809 | 304,631 |

| Michigan | 39,579 | 160,052 | 412,717 |

| Minnesota | 29,000 | 46,000 | 64,312 |

| Mississippi | 2,895 | 25,000 | 64,000 |

| Missouri | 24,379 | 103,587 | 295,817 |

| Montana | 2,000* | 24,440 | 60,646 |

| Nebraska | 33,861 | 100,534 | 223,000 |

| Nevada | 900* | 4,919 | 10,464 |

| New Hampshire | 5,764 | 17,508 | 34,680 |

| New Jersey | 43,056 | 104,341 | 226,459 |

| New Mexico | 911 | 8,228 | 22,109 |

| New York | 107,262 | 317,866 | 651,796 |

| North Carolina | 6,178 | 33,904 | 140,860 |

| North Dakota | 8,997 | 40,446 | 90,840 |

| Ohio | 63,066 | 252,431 | 616,800 |

| Oklahoma | 6,524 | 52,718 | 204,300 |

| Oregon | 10,165 | 33,917 | 103,790 |

| Pennsylvania | 59,357 | 230,578 | 570,164 |

| Rhode Island | 8,565 | 21,406 | 50,375 |

| South Carolina | 10,000* | 19,000* | 92,818 |

| South Dakota | 14,481 | 44,271 | 122,000 |

| Tennessee | 9,973 | 30,000 | 101,852 |

| Texas | 35,187 | 197,687 | 427,634 |

| Utah | 2,576 | 13,507 | 42,604 |

| Vermont | 4,283 | 15,671 | 31,625 |

| Virginia | 5,760 | 35,426 | 134,000 |

| Washington | 13,990 | 60,734 | 175,000* |

| West Virginia | 5,349 | 20,571 | 78,862 |

| Wisconsin | 24,578 | 115,637 | 293,298 |

| Wyoming | 1,300 | 7,125 | 23,926 |

| Totals | 1,007,882 | 3,584,567 | 8,887,572 |

| *Estimated | |||

and after the outbreak of the World War. During the former period development proceeded normally, from both a technical and a commercial standpoint. Great Britain had the greatest number of cars in use, but France was the greatest producer, about one half of the French production being exported. In continental Europe the introduction of motor-cars was hampered by heavy taxation on the cars themselves and on the fuel. The use of motor-trucks, on the other hand, was encouraged by the so-called subsidy system, by which purchasers of trucks suitable for military purposes were offered by their Governments a bonus on the purchase price and also on the upkeep cost, in considera- tion of their keeping the trucks always in fit condition and agree- ing to turn them over to the Government in case of war. Great Britain, France and Germany had such subsidy systems before the war; Japan adopted the same policy later. As soon as war was declared the motor-car factories were set to work for the war departments, either making trucks or other vehicles for the transport corps or else manufacturing aero-engines or munitions. Soon all the petrol available was needed in war service and the use of motor vehicles by private parties practically ceased. In England some use was made during the war period of town gas for motor fuel; this was carried in a collapsible bag of rubberized fabric, on the roof of single-deck omnibuses for instance. With this fuel it was possible to obtain about 85% as much power from an engine as with petrol, and a satisfactory mileage on one filling was secured. Under normal conditions the gas would have been carried in steel bottles under high pressure, but owing to military requirements no steel could be spared for this purpose. The Cen- tral Powers suffered much more from fuel shortage than did th Allies, and extensive researches on substitute motor fuels were carried out in Germany. After their petrol supply ran low the Germans used benzol, petroleum mixtures, benzol-alcohol mix- tures, alcohol, wood alcohol, tar oil, gas oil and shale oil, as well as compounded fuels known under the names of electrol, bene- dixine and melanol. Shale oil was derived from a raw material said to be intermediate between bituminous clay and lignite. Benzol was recognized as a valuable motor fuel, and its use con- tinued, even after petrol was again available.

Registration in Great Britain. The British Ministry of Trans- port during the summer of 1921 issued a statement of the num- ber of motor vehicles of different kinds for which licences had been issued under the new motor vehicle tax law during period Jan. i-May 31 1921. These included 212,000 privat passenger cars, 370,000 motor-cycles, 95,300 public passenge vehicles and 16,000 lorries. According to the same authorit there were licensed in Great Britain on March 31 1920, 185,70 private passenger cars, 278,600 motor-cycles and 71,400 public passenger vehicles, there being no record of the number of lorrie for that dale.

Registration in the United States. The figures given in Tabl I are based on information furnished to Automotive Industrie. by the registration officials of the different states. Allowance were made for re-registration of cars sold by their owners dur- ing the registration year and for registration of cars by non- residents, and the table is believed to give as accurately possible the number of cars in service in each state during the years mentioned by residents of the respective states.

Registration in Canada. Table II. shows that from 1915 to 1919 the number of cars registered increased over 279%.

| Province | 1910 | 1915 | 1919 |

| Ontario | 4,200 | 42,346 | 144,804 |

| Saskatchewan | 531 | 10,225 | 56,855 |

| Quebec | 786 | 10,112 | 33,547 |

| Alberta | 423 | 5,832 | 34,000 |

| Manitoba | 1,524 | 9,225 | 30,118 |

| Br. Columbia | 1,026 | 8,360 | 22,420 |

| Nova Scotia | 148 | 1,841 | 10,290 |

| New Brunswick | 299 | 1,900 | 8,306 |

| Prince Edw. I. | — | 35 | 790 |

| Yukon | — | 69 | 89 |

| Totals | 8,937 | 89,945 | 341,219 |

Technical Developments. In 1908 the "Silent Knight" engine, invented by Charles Y. Knight of Chicago, was adopted by the Daimler Motor Co. of Coventry, England, and within the next few years licences for its manufacture were taken out also by leading manufacturers of France, Belgium and Germany. This engine was notable for its almost silent operation, due to a form of sleeve valve employed, and its introduction had a strong influence on engine development in general during the next few years. In the Knight engine (fig. i) the usual poppet valves are dispensed with, and in- stead there are two concentric sleeves between the piston and the cylinder wall. These sleeves are reciprocated by means of short connecting rods from .a short-throw crankshaft which is driven at one-half the speed of the regular crankshaft; when ports in the two sleeves and in the cylinder wall are in register there is com- munication between the combustion chamber and either the inlet or exhaust manifold. In 1908 noise was one of the most serious objections to the ordinary motor-car, and designers of poppet-valve engines were spurred on by the competition of the Knight engine in their efforts to make their engines silent too. They achieved re- markable success by lightening the valves and parts reciprocating with them, by refining the cam outlines, stiffening the camshafts, adopting silent drives for the camshafts and enclosing the valve mechanism. A most desirable feature in a motor-car is flexibility, that is, the ability to pass from a low to a high speed by merely opening the throttle valve. This is secured by using an engine of great piston displacement (a powerful engine) in proportion to the combined weight of the car and load. The much better performance of modern cars, as compared with earlier ones, from the control or " handling " viewpoint, is largely due to the use of much greater piston displacement relatively. American cars have been specially noted for their flexibility, due to the use of very large engines not with- standing high fuel consumption per mile travelled. As motor fuel was much more expensive in Europe, European designers could not ignore the factor of fuel economy as American engineers could.

In engine design the constant endeavour was to get greater output

from an engine of given piston displacement. Horse-power output

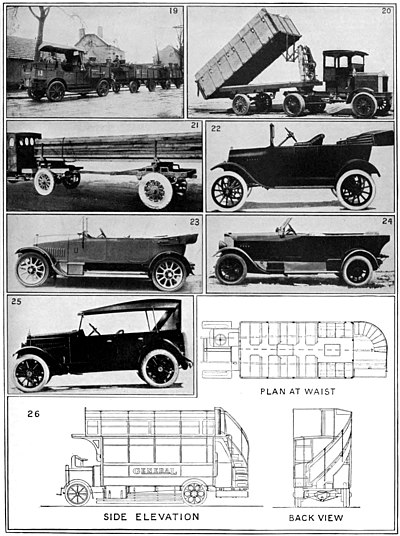

| Fig. 19.—Schneider Tractor with Two Trailers. | Fig. 23.—Humber. |

| Fig. 20.—Trailer. | Fig. 24.—Mercedes. |

| Fig. 21.—Pole Trailer. | Fig. 25.—Packard. |

| Fig. 22.—Ford. | Fig. 26.—New Type Double-Deck Motor Omnibus. |

Fig. I.—Section through cylinder of Knight sleeve-valve engine.

depends upon two factors, the mean effective pressure upon the piston head and the linear speed of the piston. It was not possible to increase greatly the mean effective pressure; in fact, changes in the character of the fuel used for motor-cars, by which some very much less volatile fractions were included than were found in motor fuel of the earlier period, made it necessary to operate with lower compression, which resulted in a lower mean effective pressure. Improvements in combustion chamber design and other changes more than balanced this loss however. A great gain was made by increasing the speed of operation. In 1905 the average engine speed corresponding to maximum engine output was about 1,000 ft. p.m.; in 1920 it was above 2,000 ft. p.m. for passenger-car engines and over 3,000 ft. p.m. for -racing engines. The first step in endeavouring to increase engine speed was the enlargement of valve ports and passages, to enable the engine to draw in a normal amount of charge at a higher speed. The valve timing was also changed, the exhaust valve being given a greater lead and the inlet valve a greater lag. Next, the reciprocating parts (piston and connecting-rod) were lightened, so as to reduce the inertia forces on them and the bearing pressures resulting therefrom. This led eventually to the adoption of aluminium alloy pistons. One difficulty with aluminium pistons is that owing to the fact that aluminium has a higher coefficient of heat expansion than cast iron, the aluminium piston must be given a greater clearance in the cylinder, which tends to result in unpleasant piston slap when the engine is cold, and also in "oil pumping," that is, transfer of lubricating oil from the crankchamber to the combustion chamber, with consequent smokiness of the exhaust. For this reason some makers who had adopted aluminium pistons gave them up. Special means were resorted to in attempts to build ultra high-speed engines, as for racing and similar purposes. These included the use of two inlet and two exhaust valves per cylinder, the use of two simultaneous ignition sparks in each cylinder, and the use of crankshafts in which each individual throw was counterbalanced.

It was recognized early in the history of motor-car development that by increasing the number of cylinders above the one or two employed in the first machines, not only could the engines be reduced in weight, but the objectionable vibration could be minimized. In 1920 the four-cylinder engine was the foremost type for use on vehicles of a strictly utilitarian character. The six-cylinder engine was, however, widely used for the larger and more powerful types of passenger car, particularly in the United States, and the eight- and twelve-cylinder engines also had a run of popularity. In a petrol engine the torque impressed upon the crankshaft is always nonuniform, no matter how many cylinders there are, but the fluctuations decrease with an increase in the number of cylinders. In a four-cylinder engine there is, as with one or two cylinders, a reversal of the torque; that is, just before the end of each stroke the flywheel not only supplies all the power delivered by the engine, but also some of the power necessary for keeping the crankshaft and pistons in motion. Six cylinders are the smallest number delivering continuous torque at the crankshaft; but while continuous the torque is still far from being uniform; with eight cylinders the torque fluctuations are reduced, and with twelve they are still smaller. Four- and six-cylinder engines were always arranged vertically, with all cylinders in a row; eight-cylinder engines were generally of the V type with an angle of 90º between cylinders. The Lincoln eight-cylinder car had a 60º V engine, and several all-in-a-row eights were built; twelve-cylinder motor-car engines were always built in V form, with a 60º angle. In deciding upon the form of the crankshaft of a multi-cylinder engine and the angle between cylinders in a V engine two objects are aimed at, namely, to ensure uniform spacing of explosions and inherent balance of reciprocating parts. Both objects can be attained in six- and eight-cylinder vertical engines and in twelve-cylinder V engines; in a four-cylinder vertical engine there is an unbalanced reciprocating force in a vertical plane, causing vibration of the engine. In an eight-cylinder 90º V engine there is an unbalanced reciprocating force in a horizontal plane.

When multi-cylinder engines were first used the cylinders were generally either cast separately or in pairs; later it became the practice to cast all cylinders in one row in one block. This greatly simplified the outward form of the engine, as with such a cylinder block only one pipe connexion each need be made for the cooling-water inlet, the cooling- water outlet, the combustible charge from the carburetter and the exhaust. Some manufacturers even cast the top part of the crankcase integral with the cylinder block and made the lower part a steel pressing. This construction lent itself well to quantity production. Most makers of the higher-priced cars, produced in smaller numbers, cast all parts of the crankcase of aluminium. In American practice the cylinder heads were generally cast separate from the cylinder block and fitted to the block with a gasket of sheet copper and asbestos between. This construction facilitated manufacturing operations, and when the engine was in service permitted decarbonizing the combustion chamber by scraping without removing the cylinder. It also made it possible to machine completely the combustion chambers, and thus to get all the chambers in one engine of exactly equal volume. European engineers up to 1920 adhered largely to the integral cylinder head.

One thing that caused both manufacturers and users of motorcars a great deal of trouble between 1910 and 1920 was the continual change in the volatility of the fuel used. When motor-cars were first used the fuel sold consisted of a comparatively narrow range of highly volatile hydro-carbons. When sprayed into air at atmospheric temperature in the required proportion of about one part by weight of petrol to 15 parts of air it vaporized readily. The fuel supplied in the United States in 1920 had an end point of close to 500º F., that is, the least volatile constituents, when under atmospheric pressure, boiled only at that temperature. Hence, in order to vaporize this fuel completely it was necessary to supply heat to the mixture or to the components before they were mixed. When trouble from incomplete vaporization was first experienced the carburetters were provided with a jacket through which hot water from the engine jacket was circulated. When this no longer sufficed the air for the carburetter was drawn through a muff surrounding a part of the exhaust manifold, and to prevent recondensation after the mixture was formed the inlet manifold was so arranged that it was completely surrounded by hot water. Still later this also proved inadequate, and then what is known as the hot spot or exhaustheated manifold was introduced. When the fuel is incompletely vaporized the liquid particles tend to separate out of the mixture at the bends in the manifold, and it is very difficult to insure that all cylinders get mixture of the same composition. Those portions of the manifold wall where the liquid particles tend to accumulate are then made to form parts of the exhaust manifold wall also, so that they are constantly kept at a high temperature, and the liquid particles upon striking them flash into vapour. The change in the character of motor fuel between 1916 and 1919 is strikingly illustrated by the diagram (fig. 2) of distillation curves of fuels purchased in Detroit, Mich., at various times during 1916-19.

One difficulty encountered in the use of exhaust heat for vaporizing the fuel is that the heat supplied does not vary in accordance with the needs when the load on the engine is varied. When the engine is heavily throttled and runs under light load at low speed, the suction on the spray nozzle is small, and consequently the fuel is not finely sprayed. Relatively more heat is needed to ensure the vaporization of the larger globules of fuel, but under these conditions of operation the exhaust does not supply a great amount of heat. A device designed to overcome this difficulty was developed by the Packard Motor Car Co., and is known as the Fuelizer. With this (see fig. 3) a variable fraction of the mixture prepared in the carburetter mixingchamber is shunted around the throttle valve and through a heating jacket of the carburetter, where it is kept burning by a constant stream of sparks delivered by a sparking plug. The products of combustion are combined with the main stream of combustible charge and pass on into the cylinder. When the throttle valve is fully open

Fig. 2.—Distillation curves of motor fuel sold in Detroit, Mich., from 1916 to 1919. The data for each curve are as follows:—

| A table should appear at this position in the text. See Help:Table for formatting instructions. |

Curve No. 9 10

Fuel Petrol Petrol Petrol Petrol Petrol Petrol Petrol Alcohol Cal. Dist. Paraffin

Date of Purchase

4/5/16 7/10/16 9/11/16

6/9/17 1/24/19

4/30/19

6/18/19

10/18

18

18

Baum6 60-5

57-5 56-8 56-8 57-3 55-7 55-o 42-2

5i-4 40-0

there is very little resistance to the passage of the combustible mixture past it, and very little then flows through the by-pass or heating jacket; on the other hand when the throttle is nearly closed the passage through it offers much more resistance, and a much greater proportion of the fuel charge passes through the heating jacket, which is in accordance with the requirements.

In early cars the fuel tank was almost invariably located in the front seat, and the fuel was fed by gravity to the carburetter. Later the bodies were constantly lowered, partly to secure greater stability and partly for the sake of appearance, and at the same time the carburetter had to be raised in relation to the engine, owing to the lessened volatility of the fuel. The result was that sometimes when the car had to ascend a steep grade and there was little fuel in the tank there was no head on the fuel, and none would flow to the carburetter. Some of the earlier high-class cars were provided with a pres Spark Plug

sure fuel feed system, by which gas under pressure, taken through an " adapter " from the engine cylinders, was made use of to force petrol from a tank carried on the frame at the rear to the carburetter. There were two major objections to this system of feed: carbon particles from the engine cylinder often got into the fuel tank (in spite of the gas being passed through a fine- mesh wire-gauze strainer) and thence into the carburetter jet, which sometimes became clogged; besides, every time the fuel tank was filled the compressed gas escaped, and to get an initial flow it was necessary to obtain pressure by a hand air-pump. By placing the fuel tank under the cowl instead of in the front seat sufficient head for gravity feed was generallyobtainable, but the cowl tank usually had an awkward shape and was of rather small capacity. The solution was found in the vacuum feed system, which was developed by the Stewart-Warner Speedometer Corp., Chicago. By this system (fig. 4) the suction or vacuum in the inlet pipe of the engine was made use of for transferring the fuel from a rear tank to an auxiliary tank mounted on the forward side of the dashboard, as high as possible. The auxiliary tank had two compartments, an upper and a lower. Into the upper compartment the fuel was drawn by the vacuum, and it was periodically transferred to the lower by a float valve. Thence it flowed to the carburetter by gravity. There was always sufficient fuel in the carburetter float chamber and in the auxiliary tank to start the engine after the main tank had been refilled.

In 1910 ignition on practically all motor-cars was by high-tension magneto. In 1920 nearly all American makes of passenger car had battery and coil ignition. French manufacturers were also adopting battery ignition, while British manufacturers with few exceptions adhered to the magneto. The reason for the change from magneto to battery ignition was that all passenger cars in 1920 were equipped with a generator and storage battery; consequently there was a constant and plentiful supply of current available, and there was no need for an additional current generator in the form of a magneto. As compared with the early coil and battery systems, the only differences consisted in the use of a plain coil instead of a vibrator coil and of a mechanical interrupter instead of a timer. Sometimes safety devices were provided for automatically opening the circuit or reducing the current flow if the operator should forget to open the switch when the motor stalled. No fundamental changes were made in the cooling system with the exception of the introduction of the thermostat for the control of the circulation. This instrument is connected in the cooling circuit in such a manner that it prevents circulation through the cylinder jackets until the latter have attained a certain predetermined temperature, generally about 170 F. The result is that in starting from cold the engine reaches its normal working temperature in much shorter time, and trouble due to incomplete vaporization of fuel is reduced. The thermostat used, known as the Sylphon, consists of a corrugated copper cylinder filled with a liquid which vaporizes at the temperature at which the thermostat is to act (fig. 5). Many passenger-car radiators are fitted with a radiator thermometer in the filler cap, which is a help to the operator in trying to keep his engine running at its best temperature and gives an early indication of incipient overheating.

Fig. 3.—Cross section of Fuelizer on Packard "Twin-Six" engine.

Fig. 4. Cut-away view of Stewart vacuum tank (fuel feed system).

Fig. 5. Thermostatic valve for control of engine temperature.

The problem of engine lubrication was rendered much more difficult by the change in the character of the fuel used. A good deal of the fuel entered the cylinder in the unvaporized state, and some of it leaked past the pistons into the crankcase, where it diluted the lubricating oil. In 1920 it was a common experience to find a fresh supply of lubricating oil lose much of its viscosity, and hence of its lubricating value, during the first 100 m. of running. Heating of the crankcase oil also reduces its viscosity, and to reduce this heating many British engines were cast with cooling flanges on the bottom of the oil sump.

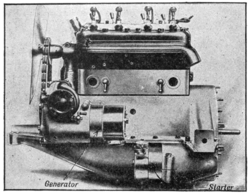

One of the greatest advances in motor-car practice was the development of electric starting and lighting systems. The first such system on a car in regular production was on the Cadillac in 1912, and was the design of C. F. Kettering. Electric lighting alone had been used on petrol cars for some years previously, in fact ever since the advent of the tungsten filament bulb. At first the lamps were supplied with current from a storage battery only, which had to be recharged periodically from electric mains; later they were fed with current from a generator and storage-battery installation. The adaptation of an electric generator to storage-battery charging on a motor-car presented considerable difficulties, for the reason that the petrol motor runs at widely varying speeds, and that the voltage of the generator, therefore, tends to vary within wide limits, whereas a substantially constant voltage is needed for charging. Many systems of regulation were used with more or less success, but finally the socalled third brush system was adopted by a majority of the manufacturers of electrical equipment. In this system the generator field was provided with a winding similar to a shunt field winding, but instead of being connected between the positive and negative commutator brushes it was connected between one of these brushes and an auxiliary brush, so that only a fraction of the voltage generated in the armature was applied to the field coils. This system of control did not give a constant generator voltage, but with a storage battery connected to the generator it kept both the voltage and the charging current within permissible limits of variation. In connexion with the electric starter the main problem was that of the drive to the engine crankshaft. After trying various devices nearly all manufacturers in the United States and a good many in Europe settled upon the use

Fig. 6. Bendix drive for electric starters.

of the Bendix drive (fig. 6), invented by Vincent Bendix of Chicago. On an extension of the starter armature shaft was loosely mounted a sleeve, which was placed in driving connexion with the shaft through a coiled spring. The spring had a coarse, square thread cut on its outside, and on this was mounted the driving pinion, the hub of which was cut with a corresponding female thread. When current was applied to the starting motor, which was always of the series wound type, the armature started to revolve at great speed, carrying along the threaded sleeve on its shaft. Owing to its inertia the pinion lagged behind, and was screwed along the shaft and thus shifted into mesh with a gear-ring on the flywheel rim. Upon abutting against a collar it became fast upon the sleeve, and the starter then cranked the engine, the shock being relieved by the coiled spring. As soon as the engine began to pick up its cycle the flywheel ran ahead of the driving pinion, and the latter was automatically thrown out of mesh by being forced along the screw. Fig. 7, illustrating the Fiat motorcar engine, shows one method of mounting the generator and starter. A necessary part of practically all motor-car electric equipments was a battery cut-out, which automatically disconnected the battery from the generator when the engine speed dropped so low that the generator voltage was less than the battery voltage, and connected it on increasing engine speed when the generator voltage surpassed the battery voltage. Ground return wiring was very much used, all electric appliances having one insulated and one grounded connection. The standard voltage for motor-car electric systems in the United States was six volts, while in Europe a pressure of 12 volts was much used.

Unit-power-plant construction, that is, the combination of the engine, clutch and change-speed gear in a single unit, became very popular, and in the United States was the almost universal practice for passenger cars. A new type of clutch, the dry-disk, largely replaced the multiple-disk-in-oil type and also partly the cone clutch (fig. 8). It was very similar to the lubricated type of disk clutch in construction, but one set of the metal disks was faced with disks of asbestos fabric on both sides. Its advantage over the lubricated disk clutch was that its operation was not affected by changes in atmospheric temperature, as was that of the latter. There were no important developments in the design of gearsets or transmissions;

Fig. 7. Fiat (Italian) engine, showing method of mounting electric generator and starter.

nearly all manufacturers of passenger cars used the selective sliding pinion type, and this type was also on most commercial vehicles.

Chain drive was almost entirely discarded, except on trucks in continental Europe, and shaft and bevel-gear drive became the standard for passenger motor-cars throughout the world. But two important improvements were made in this drive. One was the substitution of spiral bevel for straight bevel gears, to secure quiet operation, and the other the partial substitution of disk universal joints for the metallic type, the former requiring no lubrication. The spiral bevel gear (fig. 9) was made possible by a gear-cutting machine developed by the Gleason Works of Rochester, N.Y., and the fabric disk universal joint (fig. 10) by a fabric structure originated by Ed. J. Hardy & Co. of Coventry, England. Practice in regard to final drives for motor lorries remained in a chaotic state in 1920. In continental Europe the chain drive was still predominant, while in

Fig. 8. Sectional view of dry-disk clutch.

Great Britain and the United States the worm drive was in most extensive use. Of the lorry models manufactured in Great Britain in 1920 roughly 50% had worm drive, 25 % chain drive and 25% the double-reduction drive, or drive by one pair of bevel and one pair of spur gears enclosed at the middle of the axle. In the United States the most popular drive next to the worm was the internal gear drive, in which there was a first reduction by bevel gears at the middle of the axle and a second by internal gears at the driving wheels.

In connexion with lorry axles mention should be made of the development and use, mainly in the United States, of so-called nonstalling differential gears. A vehicle fitted with this type of differential would not lose all traction when one driving wheel gets on slippery ground; on the other hand, in turning corners the drive was

Fig. 9. Central part of a rear axle with inspection cover removed, showing spiral bevel gear.

entirely through the inner wheel. A type of body suspension spring that gained much in popularity between 1910 and 1920 was the cantilever type first used by F. W. Lanchester in England. The most extensively used type in 1920 was the half-elliptic. Many attempts were made to solve the problem of furnishing the springs with effective means of lubrication, to make them as supple as possible and to prevent squeaking, and in England the practice of enclosing the springs in leather gaiters gained some ground. In the connexion between the rear axle and the frame provision must be made for taking up the driving thrust necessary to overcome the air resistance and the resistance encountered by the front wheels, as well as the reaction to the rear-wheel driving torque, which tends to turn the axle housing in the direction opposite to that in which the wheels are turning. In one construction, known as the Hotchkiss drive, both the drive and the torque reaction were taken up on the body springs, which were securely clipped to the axle housing and directly pinned to the frame at their forward end. This construction became very popular in the United States for both passenger cars and lorries, and was successfully used even on the heavy military lorries. European designers, on the other hand, favoured the torque-tube construction for passenger cars. In this the propeller shaft was surrounded by a torque tube which was rigidly secured to the housing at the centre of the rear axle, and at its forward end had either a forked or a spherical connexion to a cross member of the frame or the rear end of the transmission case. In the United States one manufacturer after another

Fig. 10. Thermoid-Hardy fabric universal joint.

adopted the plan of mounting the steering post on the left side, realizing that in a country where the "right-hand" rule of the road obtains the balance of advantages rests with the left-hand drive. Left-hand steering fits in well with brake and gear-shift levers mounted in the centre of the car, as the driver can use his right hand to operate them. In Great Britain, where the rule of the road is to "keep to the left," right-hand steering has the same advantages as left-hand steering in other countries.

Great improvements were made in hoods and wind-screens. Hoods of 1920 cars could readily be raised and lowered by a single person. The forward end of the hood usually joined up to the wind-screen supports, and by means of easily folded side curtains with transparent celluloid inserts, an open car could quickly be enclosed. Wind-screens were usually in two parts and permitted various adjustments. By setting the lower edge of the upper part slightly forward the driver obtained a view of the road ahead through the opening between the two parts. This was a valuable feature for driving in rain, when the screen was often covered by dew which interfered with vision through it. It was known as the rain-vision effect. In Germany it became customary to provide a compartment in the body into which the hood disappeared when folded. Elsewhere a boot or cover of some rainproof material was drawn over the hood when it was folded. In the early two-part wind-screens both glasses were completely surrounded by the frames, and the frame members at the middle of the, screen interfered to a certain extent with the view ahead. This objectionable feature was eliminated by confining the frame to three sides of the glass. Windscreens of this type were known as clear- vision. Extra wind-screens ahead of the rear seat were sometimes fitted.

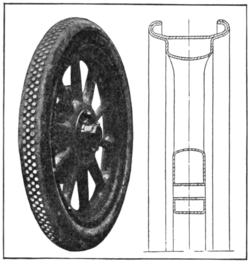

The wheel equipment of the earlier cars was almost entirely of the wood-spoked type. Woods suitable for rims and felloes became rare, however, especially in Europe, and a strong tendency toward the use of metal wheels then set in. In fact, with one or two exceptions, all British manufacturers of passenger cars fitted metal wheels as regular equipment on their 1920 models. There were three types of metal wheels for passenger cars viz. wheels similar in shape to wood-spoked wheels, made of two steel pressings welded together

Fig. 11.—Section of Rudge-Whitworth demountable wire with Pugh triple lacing.

(chiefly used in England), wire-spoked wheels and disk wheels (figs. 11, 12, and 13). An improvement in wire-wheel design, which was a great factor in rendering these wheels practical for heavy, powerful vehicles, was the triple lacing due to John V. Pugh of England. Disk wheels came into extensive use during the war; they may be divided into single and double disk types. To secure the necessary lateral stiffness with a single disk it was customary to cone the disk, and, moreover, the disk was usually

Fig. 12.—Michelin disk wheel, outside view and section.

reduced in thickness from the hub toward the rim, either by turning in the lathe or by rolling. All motor vehicle wheels are provided with steel rims designed to take the pneumatic or solid rubber tires. The original type of motor vehicle rim for the double-tube pneumatic tire was the clincher rim, the edges of which are formed into clinchers to hold the beaded edges of the tire cover. This type of rim remained the standard in Europe, but American manufacturers early adopted the detachable rim, which permits of the use of a steel cable core in the edges of the tire cover to make it inextensible. In the earlier detachable rims one flange of the rim was removable, and the tire could be stripped off sideways after the flange had been detached. Some of these detachable flange rims could be used with both clincher and straight-sided tires, and were therefore known as universal rims. Later, when the clincher tire was given up by American manufacturers for all except the smallest sizes, a different type of detachable rim was introduced, in which there is a joint in the circumference of the rim. After opening; the locking mechanism of this joint the rim can be contracted sufficiently to pass through the tire. In order that detachable rims may always be free-working the rims must be thoroughly rust-proofed, and care must be taken in handling the rim not to distort it.

In the early years of the motor-car, when a tire was punctured or otherwise defective, the operator was obliged to make a repair on the spot, or at least remove the tire cover, insert a new tube, replace the cover and inflate the tire anew. This was always an unpleasant interruption of a pleasure drive and a most aggravating occurrence in the case of an urgent business trip. The difficulty was overcome by the adoption of the demountable wheel in Europe and the demountable rim in America. American motorists thereafter carried one or two spare rims fitted with fully inflated tires, and in case of a puncture merely removed the rim with the defective tire and replaced it with a spare rim and inflated tire, an operation usually requiring from 10 to 15 minutes, leaving the repair of the damaged tire to be done at home or at a tire service station. European motorists carry spare wheels with inflated tires in the same way. The advantage of the demountable rim over the demountable wheel is that the spares weigh less; the advantage of the demountable wheel is that it weighs less than a wheel with a demountable rim, and especially that with it there is less weight near the circumference of the wheel, where it has a strong flywheel action. Moreover, with the detachable wheel the detaching mechanism is at the hub, farther removed from rust-promoting influences.

Fig. 13.—Sankey pressed steel wheel, and section.

The structure of demountable rims may be briefly described as follows: forced over the felloe of the wood wheel is a steel felloe band with a wedge surface on its outside, and an inward flange on one edge through which and the wood felloe pass the felloe band bolts. Over this felloe band is passed the rim carrying the tire, which is formed with a wedge surface on its inside, adapted to engage the wedge surface on the felloe band. Rim lugs with wedge-shaped projections are threaded over the ends of the felloe band bolts, and the nuts on the bolts are then screwed up, forcing the wedges into the space between the felloe band and the rim. In this way the rim is subjected to both radial and lateral pressure and is centred and firmly held on the felloe band. Both clincher and detachable rims can be used in connexion with demountable rims.

Solid rubber tires are vulcanized on to the steel base bands, and wood wheels to be fitted with such tires have a steel felloe band shrunk over them. The tires are then mounted on the wheels in a demountable way by means of wedge rings, side flanges and bolts. Cast-steel wheels generally have one wedge ring cast integral and do not need a side flange on that side.

There is one notable difference in the commercial practices of American and European motor-car manufacturers. In the United States it is customary to sell cars complete with bodies and all necessary equipment, so that upon being filled with fuel and water they can immediately take the road. The equipment usually includes such items as wind-screen, lamps, speedometer, jack, tire pump and tools. European manufacturers, on the other hand, previous to the World War, often made it a practice to sell only the bare chassis and let the customer arrange for the body with a coach-builder and select the equipment himself. After the war they showed an inclination to follow the American practice, especially with low-priced cars.

Many of the cars produced in the United States were made on what is known as the assembling plan; that is, the various major components, such as engine, clutch, gearset, axles, frame, springs and steering gear, were all manufactured in different factories by concerns specializing in these products, and were assembled into a

Fig. 14.—Central longitudinal section of typical American four-cylinder passenger car of 1920 (Allen). (1)—Engine cylinder head; (2)—Radiator; (3)—Headlight; (4)—Mud-guard; (5)—Filler plate; (6)—Splash plate; (7)—Engine starting shaft; (8)—Fan; (9)—Fan belt; (10)—Camshaft gear; (11)—Crankshaft main bearings; (12)—Oil pan; (13)—Engine water jacket; (14)—Camshaft; (15)—Hood; (16)—Radiator stay-rod; (17)—Vacuum tank; (18)—Dashboard; (19)—Cowl; (20)—Instrument board; (21)—Speedometer drive; (22)—Oil circulating pump; (23)—Friction clutch; (24)—Change-speed gear; (25)—Dash lamp; (26)—Speedometer; (27)—Steering post; (28)—Spark and throttle levers; (29)—Steering wheel; (30)—Wind-screen; (31)—Steering-post bracket; (32)—Brake pedal (on left of steering post), Clutch pedal (on right of steering post); (33)—Accelerator pedal; (34)—Emergency brake lever; (35)—Gear lever; (36)—Toe-board; (37)—Foot-board; (38)—Knee-board; (39)—Universal joints; (40)—Exhaust pipe; (41)—Silencer; (42)—Storage battery; (43)—Propeller shaft; (44)—Spiral bevel crown gear; (45)—Frame; (46)—Fuel tank; (47)—Fuel tank gauge; (48)—Fuel tank filler; (49)—Spare rim; (50)—Body; (51)—Rear window; (52)—Hood bows; (53)—Foot-rail; (54)—Radiator thermometer; (55)—Brake; (56)—Brake equalizer shafts.

complete car in the assembling plant. The advantages of this plan are obvious and include the possibility of intensive development of design and the economy of quantity production. The extent to which assembling was practised may be judged from the following figures: Of the American passenger-car models for 1920 92% were fitted with stock carburetters, 75% with stock steering gears, 66·7% with stock clutches, 65·1% with stock rear axles, 58·7% with stock transmissions and 42% with stock engines, all these stock parts being made by specialists. In the field of commercial vehicles the practice of assembling was even more prevalent.

Closed cars are favoured in countries with severe climate, and in the United States 161,000 such cars were manufactured in 1919. The most popular type among American motorists was the sedan, which seated four or more persons all in one compartment. It was therefore an owner-driver's car. The smallest type of closed car was the coup6, which has seating accommodation for two or three inside, including the driver, though sometimes a fourth seat facing backward was added. Closed cars for operation by a professional driver (chauffeur) were generally either of the town-car or limousine types; both of these seat from three to five persons inside, the difference being that the limousine has the driver's seat enclosed while on the town car it is open. Typical 1920 American designs of closed cars are shown in figs. 15—18.

An intermediate type between the motor-cycle and the full-sized car, referred to as a cycle car, had considerable vogue in Europe. It had a smaller wheel tread than the standard 56 in.; the engine in most cases was a two-cylinder of less than 100 cub. in. displacement; and the two passengers often sat tandem fashion. These cars were of the simplest design and were low in price and upkeep cost.

Motor-trucks must be equipped with engines able to take them fully loaded up the steepest grades which occur on regularly travelled highways. When operated in comparatively level districts they always have a surplus of power, and it was found advantageous under such conditions to use one or two trailers with the truck (fig. 19, Pl.). The advantage is greatest where the merchandise to be transported is very bulky. This plan results in considerable economy, as from two to three times as much load can be carried on one trip as with the truck alone, with little extra expense. In continental Europe there was usually a helper on each trailer to look after the load and apply the brakes, but the use of helpers greatly reduces the gain in economy, especially where wages are high, and in the United States it was not usual to employ an extra man. It was realized that in order to make it possible to stop in an emergency the trailers as well as the truck must be braked; but the problem of braking the trailers from the truck had not been definitely solved at the close of 1920, although at least one system of air brakes and one system of automatic mechanical brakes applied through the drawbar had been worked out. Another combination for heavy merchandise transportation consisted of a road tractor, which was merely a foreshortened truck chassis, and a semi-trailer (fig. 20, Pl.). This semi-trailer was a two-wheeled construction, the forward end of which was supported on the tractor frame by means of a swivelling fifth wheel. This end of the semi-trailer could be supported by means of jacks while loading and unloading, and the tractor did not need to stand idle while these operations were going on. A particular form of semi-trailer was the pole trailer (fig. 21, Pl.),—the length of which could be varied, used mainly for transporting lumber, pipes, steel sections, etc.

Commercial Development.—Throughout the first decade of the century motor-car manufacturers in the United States either paid royalties under an alleged basic patent or else were compelled to defend themselves against charges of infringement. This patent (U.S. Patent No. 549,160 of Nov. 5 1895, issued to George B. Selden of Rochester, N.Y.; b. 1845; d. there Jan. 17, 1922) was sustained in the court of original jurisdiction in Sept. 1909, in an action against the Ford Motor Co., which had been pending since Oct. 1903. Many manufacturers had been induced to recognize the patent previous to the decision, and these constituted the membership of the Association of Licensed Automobile Manufacturers (A. L. A. M.), which at one time comprised 90% of the industry. But during the last few years of the litigation many new firms started in business without taking out a Selden licence, and some members of the A.L.A.M. either ceased or delayed paying their royalties. The decision greatly strengthened the position of the A.L.A.M.,

Figs. 15 to 18.—American 1920 closed-car designs (Lincoln).

and the organization of the unlicensed manufacturers, the American Motor Car Manufacturers Assn., dissolved. The Ford Motor Co., however, appealed against the decision of the lower court, and in Sept. IQII the U.S. Circuit Court of Appeals, Second Circuit, reversed the decision. The patent was held valid but not infringed, as Selden's engine was a two-stroke, constant pressure or Brayton cycle engine, whereas the engine used by the defendant (and by practically every other motorear manufacturer) was a four-stroke, constant volume or Otto cycle engine. The judges in their opinion said:

"He (Selden) undoubtedly appreciated the possibility of the motor vehicle at a time when his ideas were regarded as chimerical. Had he been able to see far enough he might have taken out a patent as far-reaching as the Circuit Court held this one was. But like many another inventor, while he had a conception of the object to be accomplished, he went in the wrong direction. The Brayton engine was the leading engine of the time, and his attention was naturally drawn to its supposed advantages. He chose that type. In the light of events we can see that had he appreciated the superiority of the Otto engine and adopted that type for his combination his patent would cover the modern automobile. He made a wrong choice, and we cannot, by placing any forced construction upon the patent or by straining the doctrine of equivalents, make another choice for him at the expense of these defendants, who neither legally nor morally owe him anything."

This decision came little more than a year before the expiration of the patent, and no further effort to uphold it was made. Its name having become a misnomer, the A.L.A.M. reorganized as the National Automobile Chamber of Commerce, which came to be regarded as representative of the entire automobile industry, though the Ford Motor Co. never joined it. All of the national motor-car shows in the United States from that time till 1921 were held under its auspices, and it looked after the interests of the industry also in other ways, particularly through its legal, traffic and patent departments. Similar organizations in other countries are:

Great Britain.—Society of Motor Manufacturers and Traders.

France.—Chambre Syndicate de l'Automobile et des Industries qui s'y rattachent.

Belgium.—Chambre Syndicale de l'Automobile.

Germany.—Verein deutscher Motorfahrzeug-Industrieller.

Racing. During the years 'immediately preceding the World War France had the greatest export business in motor-cars, built up by consistent technical development and skilful sales propaganda, chiefly in the form of road-racing. A series of international races held during the first decade of the century, known as the Gordon Bennett Cup Races, came to an end because the French objected to the stipulation in the Deed of Gift of the cup that in the race each country should be represented by a team of three cars, which gave a country with a small industry practically the same chance of winning as a country with a large industry. In 1911 began a new series of races for the Grand Prix of the Automobile Club of France in which each manufacturer was allowed to enter up to three cars, and there was no limit to the number of manufacturers of any one nation. In fact, the race was not on the basis of national team against national team, but on that of manufacturer against manufacturer. This race was held four years in succession (1911-4) and was revived in 1921. Owing to the continued improvement in engines and the increased speeds made possible thereby, it was repeatedly necessary to reduce the limit on the piston displacement of competing cars. Originally the displacement was limited to that of a fourcylinder engine of no-mm. bore and 2oo-mm. stroke (7-6 litres), but in 1921 the limit was 3 litres.

In England and Scotland racing on the public roads was prohibited, and the only road races in the British Isles were held in the Isle of Man. In the United States a number of important races were held in the East during the early years of the automobile movement, but owing to frequent fatalities a strong public sentiment grew up against them, and race promoters were compelled to shift the scene of their activities first to the South and then to the Middle West and the Far West. Between 1910 and 1914 a number of racing-tracks with high banking, most of them 212 m. in circumference, were built in the United States after the model of the Brooklands track in England. The first and most successful of these was the Indianapolis Speedway. It was at first attempted to hold races on these tracks at frequent intervals, but they soon began to pall on the public. Later the plan of a single annual race was adopted, European contestants were secured and large cash prizes were offered to the winners, and from that time the Indianapolis races always had an enormous attendance. It is worthy of note, however, that practically none of the large manufacturers of America entered cars in the races held in 1919 and 1920. In earlier years competition in races was regarded as a form of sales propaganda and the expenses were charged to advertising, but the public gradually came to realize that to win a race at close to 100 m.p.h. required an entirely different car from that needed by the average family, and that it would not be safe to base conclusions regarding the quality of a company's stock cars on the performance of its special racing machines. Track-racing then became a form of entertainment, expenses being met out of gate-money.

Shows. An important influence on the rapid development of the motor-vehicle industry must be ascribed to the motor-car shows held annually (except for interruptions due to the World War) in such centres as Paris, London, Brussels, New York and Chicago, under the auspices and control of the motor-car manufacturers' associations of the respective countries. The Paris show, the oldest and for a long time the largest as regards number of exhibitors, was resumed after the war, in 1919. But in 1920 the show was suspended, because at the time when preparations would have been made trade conditions seemed to make it unnecessary. London shows were held at Olympia, and in 1920 there was an overflow exhibition at the White City. Owing to the fact that Great Britain was one of the greatest markets for motor-cars, importing more cars than any other country in Europe, the Olympia show always had a strong inter- national flavour. There was a special show for commercial cars at Olympia in 1920, shortly before the passenger-car show. In the United States also truck shows had been held separately for several years. National motor-car manufacturers' associations previous to the World War had an international federation with headquarters in Paris. One of the activities of the federation was to allocate dates for national shows to all countries represented, so as to prevent conflict, which would have been annoying to manufacturers wishing to ex- hibit at several shows. The federation also endeavoured to restrict the organization of shows, to exercise a certain control over races and to influence legislation. In 1920 the original international feder- ation was dissolved and a new allied federation took its place.

Standardization, A great help to the motor-car industry in the United States was the standardization work of the Society of Auto- motive Engineers, concurrent with specialization in the manufacture of parts. One of the first things standardized was fine-pitch screw threads. It was found that the former standard threads, such as the U.S.S., Whitworth, etc., were too coarse for motor-car work, and manufacturers began devising their own fine-thread standards; if this had continued it would have led to the use of many different pitches for screws of the same diameter, which would nave been most annoying to the user. In order to obviate this the S.A.E. screw thread was evolved, and soon came into common use. A great deal of the standardization work was concerned with the joints or connexions between parts made in different factories. Thus the mountings on the engine, of carburetters, battery ignition units, magnetos, electric generators, starters and tire pumps were standard- ized, as were flywheel housings, shaft fittings, spring mountings, etc. At the end of 1920 there were about 180 separate motor-car standards on the records of the S.A.E. Great Britain had a similar technical society, the Institution of Automobile Engineers, but motor-car standardization work was carried on by a sub-committee of the British Engineering Standards Committee, on which both the Institution of Automobile Engineers and the Society of Motor Manufacturers and Traders were represented. There was also a technical society in Germany, the Automobil und Flugtechnische Gesellschaft, but it had not been active. During the World War engineering standardization work was begun in Germany by a general organization covering the whole engineering trade, and after the war motor-car standardization was continued by the Verein deutscher Motorfahrzeug-Industrieller.

Taxation. In nearly all countries motor vehicles were subject to an annual road tax based upon the rated horse-power of the engine. Great Britain did not impose such a tax until Jan. I 1921. The rate of tax was then i per horse-power, determined by the following equation :

where N is the number of cylinders and b the bore in inches. The same formula, known in Great Britain as the Royal Automobile Club formula, was used in most states of the United States, where it was known as the A.L.A.M. formula. Japan used a very similar for- mula, the denominator of the fraction being 3 instead of 2-5. Widely different formulas were in use in different countries for determining the tax horse-power. Some, like those above cited, made the horse- power proportional to the cylinder bore, others to the piston dis- placement volume, and still others to this volume and the normal speed of revolution. Let C be a constant, b the cylinder bore, I the piston stroke, N the number of cylinders, and r the normal engine speed then the various horse-power formulas used in 1920 may be written as follows :

For Belgium: H.P. =C.6 2 ./.N.r (where C varies between 3 and 3-5 for motor-cycles and between 4-5 and 5 for motor-cars, and b and / are in metres. It was customary to make C=3 and r = 1,000 for motor-cycles and C =4-5 and r = 1,000 for motor-cars).

In France the formula reads the same as that for Belgium; C is equal to 0-0002 for single-cylinder engines, 0-00017 f r two-cylinder, 0-00015 for four-cylinder, and 0-00013 for multi-cylinder, b is inserted in centimetres, I in metres, and r in revolutions per second.

In Germany: H.P. =o-3N.& 2 ./ (b being in centimetres and / in metres). Holland, Denmark, Switzerland and Russia used the same formula.

In Italy: H.P. =0-0525^.^ for passenger vehicles and H.P. = 0-0350 N.6 2 for commercial vehicles (b being in centimetres).

Ford Cars. A unique position in the American motor-car industry has been occupied by the Ford Motor Co., whose annual productionfor several years constituted about one-half that of the whole industry. This company in igog-succeeded in developing a passenger car which it was able to sell for the next 1 1 years without material modifications

in design except as regards the body and equipment. This stability of design made possible production on an unequalled scale and at remarkably low cost. At one time during the World War period this car sold in the United States as low as $325 for the two-seater and $360 for the five-seater. In 1917 the company began to produce also a light truck, and in 1920 the production of passenger cars and trucks combined exceeded 1 ,000,000 vehicles.

German Lorries. Motor-lorry services under public ownership were developed in Germany after the Armistice of Nov. 1918 from an emergency service previously established by the War Department. Toward the end of 1916 the German Government, facing a trans- portation crisis at home, was compelled to withdraw a large number of motor lorries from the front in order to relieve the congestion at freight depots and to carry agricultural produce to the great centres of population. This service was gradually extended, and during the last full month of the war, Oct. 1918, the lorries in the home service moved 302,000 tons of freight and covered an aggregate dis- tance of 922,000 m., of which 525,000 m. was with load. The useful work done amounted to 1,960,000 ton-miles and the fuel consumed to 260,000 imp. gallons. After the Armistice 16 limited liability corporations (Krojtverkehrsgesellschaften) were organized, and oper- ating territories were assigned to each so that the whole country was covered. The National Government furnished the vehicles and received in return shares of stock and certificates of indebted- ness. Most of the capital stock of the companies was subscribed by the local governments of the districts served. According to a report made in 1920 these companies then operated 98 services with a rolling-stock consisting of 2,871 motor lorries, 37 tractors, 1,079 trailers, 187 passenger cars, 126 motor-cycles and 150 motor- buses. The personnel numbered 3,000. The interests of the national Government in these companies were looked after by the Treasury Department. Lorries and other vehicles with drivers (and helpers if necessary) were furnished either on a direct ton-mile basis or by the day, in the latter case there being a limit on both the time and the distance covered, with extra rates if either limit was exceeded. Similar services for passengers and mails were established in Ger- many by the Post-Office Department. In 1920 this department established 100 new mail lines in country districts with an initial equipment of 260 vehicles ; it also added between 400 and 500 vehicles to the equipment for carrying mails in the cities.

Motor Omnibuses. The largest motor-omnibus service in the world in 1920 was that of the London General Omnibus Co., which then had more than 2,500 buses in operation. This company shortly after the World War introduced a new " K " type of double-deck omnibus with seating capacity for 46 passengers (22 below and 24 on top), which weighed no more than the 34-passenger buses in service up to that time (see fig. 26, PI.). Of the passengers carried on the lower deck six occupied a longitudinal seat while all the rest faced forward. The chassis frame and the framework of the body of this new omnibus were made of ash bars reenforced with steel flitch plates. Practically all the panels of the body consisted of three-ply birch ; the main floor was of the same material and had wearing slats secured to it, while the roof consisted of two thicknesses of this three- ply with a layer of waterproof duck between. Fully equipped for service this motor omnibus weighed 7,600 lb., of which 2,350 Ib. was body weight. The engine had four cylinders of loo-mm. bore and l4O-mm. stroke, which were cast in pairs; it developed 30 H.P. at 1,050 r.p.m. The wheelbase was l7Oj in. ; the large passenger capacity for this wheelbase was made possible by placing the driver's seat alongside the engine. On July I 1920 there were 80 of these buses in service.

War Developments. During the World War the motor-car industries of ah 1 the belligerent countries greatly increased their productive capacities, because they possessed the personnel and the equipment necessary for turning out many essentials of warfare, such as vehicles of all kinds, aero-motors and munitions. Thus the capitalization of the German motor industry increased about 1 80% between 1914 and 1919. Twenty German motor- car manufacturing concerns during this period issued additional stock to the amount of 176,350,000 marks, and bond issues and the capitalization of newly organized companies brought the capital increase up to 214,950,000 marks. There was a similar increase in the capitalization of the British motor-car industry, but most of the new issues of stock in Great Britain occurred after the Armistice, while in Germany the greatest accession of new capital took place during the war period.

During the early part of the World War the American motor industry furnished large numbers of motor lorries to the British, French and Russian Governments, and this was reflected by the export returns, which showed an increase in the number of trucks exported from 784 in 1914 to 21,265 i n 1916. At the same time the foreign demand for American passenger cars increased greatly, because the belligerent European countries could not make deliveries. In 1918, when the United States threw its full

strength into the war, motor-car exports suffered a material decline, but they jumped ahead again immediately after the Armistice, an increase of 79% being shown in 1919. That year the exports of passenger cars, lorries and parts together exceeded $100,000,000 in value, yet the passenger cars exported were hardly 4% of the total production, while the exports of commer- cial vehicles amounted to 4-9 per cent.

After the war the tide of international motor-car commerce showed great fluctuations. As soon as shipping connexions be- came reestablished there was a heavy demand, particularly in the neutral countries of northern Europe. In 1919 only the United States was in a position to export large numbers of vehi- cles, because it took the motor-car industries of the European belligerents a long time to get back to a peace basis. After a short time, however, the low rates of continental exchange and temporary embargoes on motor-car imports in several countries, including Great Britain, France, Germany, Italy, Denmark and Norway, cut down the exports from the United States. Even when the embargoes were lifted imports were restricted by high customs duties, as, for instance, 70% in the case of France.

Electric Cars. There was little progress in electric vehicles during the decade 1910-20. The electric is essentially a town car, and during the first half of the decade a good many electric passenger vehicles were in use, especially in four of the larger cities of the United States : Buffalo, Cleveland, Chicago and Los Angeles, all of which are com- paratively level and have fine boulevard systems. The electric appealed particularly to lady drivers, because it dispensed with the cranking of the petrol car and was generally simpler and less trouble- some to operate. With the advent of the electric motor starter this disadvantage of the petrol car largely disappeared. The introduction of demountable rims and power tire pumps further reduced the hard work in connexion with the operation of petrol cars as compared with solid-tired electric vehicles. The electric then became more and more a luxury vehicle, built only in expensive closed-body types and used mainly for town driving by people who owned a petrol car for coun- try driving in addition. > The electric commercial vehicle industry also was more or less stationary while the petrol commercial industry forged ahead rapidly. In 1920 the electric lorries in service in _New York City formed a small portion of all the commercial vehicles, which was not the case in 1910. A new type of electric commercial vehicle, known in the United States as an industrial truck, but per- haps better described as a floor truck or a low wheel truck, came into extensive use, especially during the war period. These industrial trucks take the place of hand trucks on steamship piers and railway station platforms, in factory buildings and paved yards. Petrol industrial trucks have also been developed, but as they are not ad- mitted to steamship piers on account of the fire hazards the electric has an undisputed field there. There was great inducement in Europe during the war, when petrol was exceedingly scarce, to develop the electric vehicle for both passenger and commercial traffic. In Germany a scheme was worked out for a system of goods transport in large cities by electric lorries with interchangeable batteries, and a few sample trucks were built, but the Armistice intervened and the scheme was dropped. The steam vehicle also retrogressed as a factor in transportation. In 1920 there was only a single concern in all the world making steam-propelled passenger cars in any con- siderable numbers, the Stanley Motor Carriage Co. of Newton, Mass., which was one of the pioneers in this line of industry. Con- siderable numbers of steam lorries were still being manufactured in England, but the steam motor-buses at one time in service in London had been taken off the streets. The petrol motor had def- initely gained the ascendency over steam and electric motors, and supplies for it could be found and repairs to it had in almost every town. In the United States, for instance, there were, at the beginning of 1920, 43,643 repair shops (besides 36,227 garages), and all of these repair shops were equipped to cater to owners of petrol cars, but only a few to owners of steam and electric vehicles, giving a tremendous advantage to the former.

BIBLIOGRAPHY. Arnold and Faurote, Ford Methods and the Ford Shops (1915); Blum, Etude sur les Vehicules Automobiles sur Quatre Roues Matrices (1913); Browne, Handbook of Carburetion (1915); Carles, L'Anatomie de la Voiture Automobile (1913); Carles, Les Accessoires de I' Automobile (1913); Clark, Textbook on Motor Car Engineering (2 vols., 1911, 1917); Fraser and Jones, Motor Vehicles and their Engines (1919); Hayward, Automobile Ignition, Starting and Lighting (1917); Heldt, The Gasoline Automobile, its Design and Construction (3 vols., 1920) ; Heller, Motorwagen und Fahrzeugma- schinen fur flilssigen Brennstoff (1912) ; Jaenichen, Automobil-Betrieb- stoffe (1915); Lacoin, Construction et Reglage des Moteurs a Ex- plosions (1910); Loewe, Konstruktionsberechnungen von Kraft- fahrzeugen und die Organization von Konstruktionsbiiros (1915) ; More- ton and Hatch, Electrical Equipment of the Motor Car (1918) ; Newmark, Automobile Business (1915); Norton, The Motor Truck as an Aid to Business Profits (1918); Page, The Modern Gasoline

Automobile (1920); Philllmore, Motor Road Transport for Commercial Purposes (1920) ; Riedler, The Scientific Determination of the Merits of Automobiles (1914); Schaefer, Motor Truck Design and Con- struction (1919); Strickland, Manual of Petrol Motors and Motor Cars (1914) ; Terry, Motor Body Building in all its Branches (1914) ; Valentin, Automobiltechnisches Ilandbuch (1913); Valentin, Fabri- kation von Motoren und Automobilen (1915). (P. M. H.)

TABLE III. Statistics of the Development of the American Industry.

| A table should appear at this position in the text. See Help:Table for formatting instructions. |

1909*

1914*

I9i9f

Capital invested Cars and lorries pro- duced . . . Value of products Persons engaged in mf g. Wages and salaries

$173.837.000

127,731 $249,202,000

85,359 $ 58,173,000

8407,730,000

569,045 $632,831,000

145,951

$139,453,000

$1,802,302,862

1,974,016 $2,506,834,594 651,450 $ 813,731,856

- From U.S. Census, f Based on statistics of complete car produc-

tion gathered by National Automobile Chamber of Commerce and on the assumption that the parts and accessories business grew in same proportion.

TABLE IV. Statistics of the American Industry for

Capital invested in passenger-car industry $784,660,761

Number of passenger-car factories . . 131

Number of open cars produced . . 1,496,652

Number of closed cars produced . . 161,000

Total number of passenger cars produced 1,657,652

Value of complete cars and lorries produced $1,885,112,546

Value of passenger cars produced . . $1,461,785,925

Value of passenger-car parts and accessories $62 1 ,722,048