and the concave; most of the corn falls through the concave on to the corn and chaff receiving board, but some of the corn and chaff remain among the straw; as the " cavings " (the short broken straw and leaf) need to be separated from the straw it is given a thorough tossing up on the shakers, which have an upwards and onwards peristaltic action, and deliver the straw at the end of the machine. The corn, chaff and cavings fall on to a reciprocating board or “upper shoe,” which carries them back to the middle

Fig. 1.—The internal construction and arrangement of the “Ruston” double crank finishing Thrashing Machine. (Ruston, Proctor & Co., Lincoln.)

Fig. 1.—The internal construction and arrangement of the “Ruston” double crank finishing Thrashing Machine. (Ruston, Proctor & Co., Lincoln.)

A, Corn feed opening. O, Grain passage.

B, Thrashing drum. P, Spout.

CC, Straw shakers. Q, Rotary screen.

D, Collecting board of top shoe. R, Grain passage.

EE, Caving riddle. T, Classified grain.

FF, Dressing riddles. U, Rotary screen brush.

G, Grain spout. V, Dust spout.

H, Large blower. W, Grain delivery to sacks.

I, Shut off lid. X, Dust.

JJ, Elevator. Z, Cavings delivery.

K, Smutter. Y, Chaff delivery or chaff collector may be fitted here to deliver chaff upon either side of machine, as desired.

L, Creeper.

MM, Riddle.

N, Second blower.

of the machine, where they meet the corn that fell through the concave. The upper shoe passes the cavings, &c, over the end into a “lower shoe,” which thoroughly sifts the corn and chaff from the cavings. The cavings are then carried along to the outside of the machine and emerge at an opening beneath the point where the straw passes out. The corn and chaff fall through the lower shoe or caving riddle on to a receiving board

Fig. 2.—Thrashing Machine at work with stacking elevator behind.

(Clayton & Shuttleworth, Lincoln.)

Fig. 2.—Thrashing Machine at work with stacking elevator behind.

(Clayton & Shuttleworth, Lincoln.)

which takes them back to the middle of the machine, where they fall, meeting with a strong blast of wind from the first fan, which blows out the chaff and light matter, the small seeds and light dust being sifted out through finely perforated sieves, while larger debris such as thistle heads and “chobs” (broken heads) are taken off by a coarse sieve. The corn then passes into the shaker shoe, which is fitted with sieves to take off the larger seed, and thence to the elevator, which carries it to the top of the machine in a roughly dressed condition. The elevator delivers the corn into the awner or “hummeller,” which is fitted with helical blades to rub off the awns or beards which may still adhere to the grain. From here the grain falls on to a second series of sieves, where it meets the blast of air from the second fan, which blows and sifts the light and coarse foreign matter from the grain, delivering this debris on the first corn and chaff receiving board to undergo separation again along with that just fallen from the concave. The corn falls from the sieve of this second dresser into a rotary screen where separations are made producing the clean sample and the tail com, which are delivered at separate openings below. There are modifications on the machine described—such as single fan-blast instead of double, &c.—but the general principles are the same. The concave which surrounds the drum is made adjustable, so that it can be regulated according to the nature of the crop to be thrashed. An ordinary machine will thrash all usual farm crops, but great care has to be taken in adjusting the concave or the seed will be injured. Clover, however, is twice

Fig. 3.—Thrashing Machine with fan-blast straw-stacker.

(Clayton & Shuttleworth, Lincoln.)

Fig. 3.—Thrashing Machine with fan-blast straw-stacker.

(Clayton & Shuttleworth, Lincoln.)

passed through a machine of this description, to free the seed from the haulm and afterwards to rub the seed clear from the chaff, but special machines to thrash it all in one operation are made.

The drum is carried on the main shaft and all other pulleys take their motion. from it directly or indirectly. Sometimes the main shaft is lengthened to accommodate another pulley and so drive a chaff-cutter behind and chaff up the straw as it leaves the thresher. In some districts an elevator is driven behind to stack the straw. Others use a trusser, which ties the straw into large. bundles before delivering it for stacking.

American Machines.—In American machines the straw, cavings, &c, are caught in a blast at the rear end of the machine and blown up in a light iron pipe of about 18 in. diameter on to the top of the stack, and the grain is delivered loose at the side through a spout into a box wagon. As the payment for thrashing is per bushel the grain is usually passed through a self-registering weighing apparatus, so that accurate account is kept of the bushels thrashed. In Great Britain payment is per quarter of 8 bushels, and as the machine delivers into 4-bushel

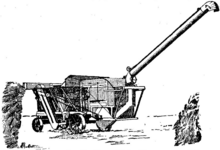

Fig. 4.—American “Separator” with self-feeder and fan-blast

delivery-pipe for straw. (Avery Manufacturing Co., Peoria, Illinois.)

Fig. 4.—American “Separator” with self-feeder and fan-blast

delivery-pipe for straw. (Avery Manufacturing Co., Peoria, Illinois.)

sacks this rough-and-ready measure is accepted. On American machines self-feeders are adopted, in which the sheaves are thrown on to a travelling web which carries them under revolving knives to cut the bands and deliver them loose into the