THERMOMETRY (Gr. θερμός, warm; μέτρον, a measure), the art of measuring temperature or degree of heat. The instruments used for this purpose are known as thermometers, or sometimes, when the temperatures to be measured are high, as pyrometers.

1. A brief sketch of the evolution of the thermometer is included in the article Heat, § 2 and 3. The object of the present article is to discuss the general principles on which the accurate measurement of temperature depends, and to describe the application of these principles to the construction and use of the most important types of thermometer. Special attention will be devoted to more recent advances in scientific methods of testing thermometers and to the application of electrical and optical methods to the difficult problem of measuring high temperatures. In the article Pyrometer an account will be found of some of the thermoscopic methods employed in the arts for determining high temperatures.

2. Zero: Fundamental Interval.—In all systems of measuring temperature it is necessary (1) to choose a zero or starting-point from which to reckon, (2) to determine the size of the degree by subdividing the interval between two selected fixed points of the scale (called the “fundamental interval”) into a given number of equal parts. The fundamental interval selected is that between the temperature of melting ice and the temperature of condensing steam, under standard atmospheric pressure. On the Centigrade system the fundamental interval is divided into 100 parts, and the melting-point of ice is taken as the zero of the scale. We shall denote temperature reckoned on this system by the letter t, or by affixing the letter C. It is often convenient to reckon temperature, not from the melting point of ice, but from a theoretical or absolute zero representing the lowest conceivable temperature. We shall denote temperature reckoned in this manner by the letter T, or θ, or by affixing the letters Abs. In practice, since the absolute zero is unattainable, the absolute temperature is deduced from the Centigrade temperature by adding a constant quantity, T0, representing the interval between the absolute zero and the melting-point of ice; thus T=t+T0.

3. Arbitrary Scales.—An arbitrary scale can be constructed by selecting any physical property of a substance which varies regularly with the temperature, such as the volume of a liquid, or the pressure or density of a gas, or the electrical resistance of a metal. Thus if V denote the volume of a given mass at the temperature t, and if V0, V1 represent the volumes of the same mass at the temperatures 0° and 100° C., the size of 1° C. on the scale of this arbitrary thermometer is one hundredth part of the fundamental interval, namely (V1−V0)/100, and the temperature t at volume V is the number of these degrees contained in the expansion V−V0 between 0° and t°C. We thus arrive at the formula

| t=100 (V−V0)/(V1−V0) | (1), |

which is the general expression for the temperature Centigrade on any such arbitrary scale, provided that we substitute for V the particular physical property selected as the basis of the scale. If we prefer to reckon temperature from an arbitrary zero defined by the vanishing of V, which may conveniently be called the fundamental zero of the scale considered, we have, putting V=0 in equation (1), the numerical values of the fundamental zero T0, and of the temperature T reckoned from this zero

| T0=100V0/(V1−V0), and T=T0V/V0=t+T0 | (2). |

It is frequently convenient to measure temperature in this manner when dealing with gases, or electrical resistance thermometers.

4. Absolute Scale.—It is necessary for theoretical purposes to reduce all experimental results as far as possible to the absolute scale, defined as explained in Heat, § 21, on the basis of Carnot's principle, which is independent of the properties of any particular substance. Temperature on this scale measured from the absolute zero will be denoted by the letter θ. This scale can be most nearly realized in practice by observing the temperature T on the scale of a gas-thermometer, and .making special experiments on the gas to determine how far its scale deviates from that of the thermodynamical engine. In the case of the gases hydrogen and helium, which can exist in the liquid state only at very low temperatures, the deviations from the absolute scale at ordinary temperatures are so small that they cannot be certainly determined. Thermometers containing these gases are generally taken as the ultimate standards of reference in practical thermometry.

Mercurial Thermometry

5. The most familiar type of thermometer depends on the apparent expansion of a liquid hermetically sealed in a glass bulb attached to a graduated stem of fine bore. Of all liquid-in-glass thermometers those containing mercury are almost invariably selected for scientific purposes, although at first sight mercury would appear to be the least suitable liquid, on account of its small coefficient of expansion. The smallness of the expansion necessitates an extremely fine bore for the stem, which introduces errors in consequence of the high surface tension of mercury. The considerable density of the liquid also tends to exaggerate the effects of change of position due to variation of the pressure exerted on the interior of the bulb by the liquid column. These errors are small and fairly regular, and can be corrected within certain limits. A much more serious source of trouble, especially at high temperatures, is the imperfect elasticity of the glass, which causes more or less irregular changes in the volume of the bulb. The effect of these changes on the readings of the thermometer is enhanced by the smallness of the expansion of mercury, and might be reduced by employing a more expansible liquid. It is more likely, however, that the defect will be remedied by the construction of thermometers of fused quartz, which is the most perfectly elastic solid hitherto discovered. For work at low temperatures the range of a mercury thermometer is limited by its freezing-point (−39° C.).

These are the serious disadvantages attending the use of mercury, but in other respects it possesses so many advantages over alcohol or other substitutes, that it will in all probability continue to be used almost exclusively in thermometers of this type for scientific work. Among its chief advantages may be reckoned its high boiling-point (357° C.), and the absence of evaporation from the top of the thread, which is so serious a source of error with the alcohol thermometer. With mercury the evaporation is almost inappreciable at 100° C., and can in all cases be avoided by exposing the upper parts of the emergent thread to the temperature of the air. Although an evacuated mercury thermometer cannot be safely used at temperatures over 300° C., owing to the breaking up of the thread of liquid in the stem, it' has been found possible, by filling the upper part of the stem with nitrogen or carbon dioxide under high pressure, to extend the range to 550° C. A more important advantage for accurate work is the fact that mercury does not wet glass, and avoids any possible errors due to adherent films of liquid on the walls of the tube. This greatly facilitates observations, and also renders it possible to calibrate the thermometer after construction, which cannot be satisfactorily accomplished with other liquids. The process of construction and calibration is further facilitated by the fact that mercury does not dissolve air to any appreciable extent. In consequence of the regularity of expansion of mercury at ordinary temperatures, the scale of the mercury thermometer agrees very closely with that of the gas thermometer. The liquid is very easily obtained in a high state of purity by distillation, and has practically no chemical action on glass. In this respect it is superior to the liquid alloy of potassium and sodium, which has been employed in some high-temperature thermometers, but which rapidly reduces silica at high temperatures. The high conductivity and low specific heat of mercury as compared with most other liquids tend to render the thermometer quick and sensitive in action. Its opacity considerably facilitates accurate reading, and even the smallness of its expansion has one great countervailing advantage, in that the correction for stem-exposure is proportionately reduced. This correction, which (even in the case of mercury) may amount to as much as 40° C. at 550° C., is far the most uncertain in its application, and is the most serious objection to the use of the liquid-in-glass thermometer at high temperatures.

6. Construction.—The construction of the most accurate type of mercury thermometer has undergone some changes of detail in recent years. The range of the most accurate standards is generally restricted to the fundamental interval. The length of a degree on the stem can be increased to any extent by enlarging the bulb or diminishing the bore of the stem, but it is found in practice that there is no advantage in making the scale more open than one centimetre to the degree C. in standard instruments, or in increasing the number of divisions beyond ten or at most twenty to the degree. Enlarging the bulb makes the instrument sluggish, and exaggerates the errors due to imperfect elasticity. Diminishing the bore of the tube increases the errors due to capillary friction. Even one centimetre to the degree is an impracticable scale for thermometers graduated continuously from 0° to 100° C., owing to the excessive length of the stem. In order to secure so open a scale, it is necessary to limit the range to 35°, or at most 50°. The fixed points 0° and 100° may still be retained, for purposes of testing and reference, by the device, now commonly employed, of blowing auxiliary bulbs or ampoules on the stem, the volume of which is carefully adjusted to correspond with the number of degrees that it is desired to suppress.

In the best instruments for Work of precision the bulb is not blown on the capillary tube itself, but is formed of a separate piece of tube fused on the stem. It is possible in this manner to secure greater uniformity of strength and regularity of dimensions. The thickness of the glass is generally between half a millimetre and one millimetre. The advantage in point of quickness gained by making the glass thin is more than counterbalanced by increased fragility and liability to distortion. The best form of bulb is cylindrical, of the same external diameter as the stem. The bore of the stem should also be cylindrical, and not oval or flattened, in order to diminish errors due to capillarity, and to secure the greatest possible uniformity of section. The glass should be clear, and not backed with opal, both to admit of reading from either side, and to minimize risk of bending or distortion. In the commoner sorts of thermometers, which are intended for rough purposes and to be read without the application of minute corrections, it is not unusual to divide the tube into divisions of equal volume by a preliminary calibration. In the most accurate instruments it is preferable to divide the tube into divisions of equal length, as this can be more accurately effected., The corrections to be applied to the readings to allow for inequalities of bore can be most satisfactorily determined in the case of mercury thermometers by calibrating the tube after the instrument is completed (see Calibration). This correction is known as the “calibration correction.” Instead of being separately determined it may be included in the scale correction by comparison with a standard instrument, such as a platinum-resistance thermometer.

7. Corrections.—The corrections to be applied to the readings of a mercury thermometer, in addition to the calibration correction, may be summarized under the following heads: (i.), Zero. (ii.) Fundamental Interval. (iii.) Internal and External Pressure. (iv.) Stem Exposure. (v.) Scale Correction, including Poggendorff’s correction.

(1) The changes of zero are of two kinds. (a) Secular rise of zero due to gradual recovery from changes or strains acquired by the bulb during the process of manufacture. This process may be hastened and subsequent changes practically eliminated by annealing the bulb after manufacture, and before final adjustment, at a high temperature, such as that of boiling sulphur (about 450° C.). A thermometer which has not been so treated may show a rise of zero amounting to as much as 20° or 30° when exposed for some time to a temperature of 350° C. (b) Temporary depression of zero after each exposure to a high temperature, followed by a slow recovery which may last for days or weeks. The best thermometers of hard glass show a depression of zero amounting to about one-tenth of 1° C. after exposure to 100° C. In softer glass the depression is usually greater and more persistent, and may amount to half a degree after 100° C. At higher temperatures the depression generally increases roughly as the square of the temperature above 0° C. It may amount to 2° or 3° at 300° C. The effect cannot be calculated or predicted in any series of observations. because it depends in so complicated a manner on the past history and on the time. It is a most serious difficulty in accurate mercurial thermometry, especially at high temperatures. The most satisfactory method of correction appears to be to observe the zero immediately after each reading. and to reckon the temperature from the variable zero thus observed. The rationale of this procedure is that the depression is produced at the high temperature much more rapidly than the subsequent recovery at the low temperature. The thermometer is taken from the bath and allowed to cool rapidly by free exposure to the air. As soon as it reaches 40° or 50° C., it is plunged in the melting ice, and the lowest point reached is taken as the temporary zero.

The following formulae have been proposed by various observers to represent the depression of zero for different kinds of glass:—

| Pernet, French cristal, dz=0·0040(t/100)2 . . . . | . (4) |

| Guillaume, Verre dur, 0–100° C., dz=(8886t+10·84t 2)10−7 | |

| Bottcher, Cristal dur, 0–190° C., dz= (7970t+329t 2)10−7 | |

| ,, Jena, 16, iii., dz=(7100t−8t 2) 10−7 . . . . |

|

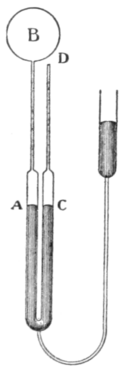

| Fig. 1.—Hypsometer. |

The symbol dz in these formulae stands for the depression of zero produced by an exposure to a temperature t. The depression is about three times as large in French crystal as in English flint glass, and varies roughly as the square of t. Verre dur and Jena, 16, iii., are varieties of hard glass chosen as standards in France and Germany respectively, on account of the comparatively small depression of zero to which they are liable. At low temperatures, up to 50° C., the depression is very nearly proportional to t, but at temperatures above 100° C. it is necessary to adopt another formula in which the term depending upon t 2 is more important. These formulae are useful as giving an idea of the probable size of thee corrections any case, but they cannot be employed in practice except in the simplest cases and at low temperatures. On account of these temporary changes of zero, a mercury thermometer intended for the most accurate work at ordinary temperatures (as in calorimetry) should preferably never be heated above 40° or 50° C., and certainly never above 100° C. Above 100° C. the changes of zero become more irregular and more variable, depending on the rate of cooling and on the sequence of previous observations, so that even if the method of observing the zero after each reading is adopted, the order of precision attainable rapidly diminishes.

(II) Fundamental Interval.—The thermometer to be tested is exposed to steam condensing at atmospheric pressure in an apparatus which is often called a “hypsometer,” constructed with double walls to protect the inner tube containing the thermometer from any cooling by radiation. The standard atmospheric pressure at which the temperature of the steam is by definition if equal to 100° C. is equivalent to that produced by a column of mercury at 0° C. and 760 millimetres high, the force of gravitation being equal to that at sea-level in latitude 45°. The atmospheric pressure at the time of observation is reduced to these units by applying the usual corrections for temperature and gravitation. If the pressure is near 760 mm., the temperature of the steam may be deduced by assuming that it increases at the rate of 1° C. for 27·2 mm. of pressure. If the pressure is not near 760 mm., the application of the correction is less certain, but is generally taken from Regnault’s tables, from which the following data are extracted. Thermometers cannot be satisfactorily tested at an elevated station where the height of the barometer H is less than 700 mm., as the steam point is too uncertain.

A convenient type of hypsometer is shown in fig. 1. The boiler B is separate from the steam-jacket A surrounding the thermometer. A gauge G is provided for indicating the steam pressure (difference from atmospheric) and a condenser C for returning the condensed steam to the boiler. The thermometer is observed by the microscope M.

| Pressure (corrected) | 790 | 780 | 770 | 760 | 750 | 740 | 730 | 720 | 710 |

| Steam temp. = 100° C., + | +1·083 | +·726 | +·365 | 0 | −·369 | −·742 | −1·120 | −1·502 | −1·888 |

| Approximate formula dt1=0·0367(H−760)−·000020(H−760)2 | (5) |

If the barometer has a brass scale correct at 0° C., and H be the reading in millimetres, the correction for temperature is made approximately by subtracting 0·00163 H mm.

If L is the latitude and M the height of the station in metres above the sea-level, the correction for gravitation is approximately made by subtracting (0·0026 cos 2L+0·0000002M) H mm.

The zero of the thermometer is observed immediately after the steam point. If n be the interval in degrees of the scale between the two observations, and if t1 be the temperature of the steam, the fundamental interval of the thermometer may be taken as 100 n/t1, provided that t1 is nearly 100° C. Since all the readings of a thermometer have to be corrected for the error of the fundamental interval, by dividing by the fundamental interval thus observed and multiplying by 100, it is a matter of some convenience in practice to have the instrument graduated so that the difference between the readings in ice and at 100° C. is very nearly 100° of the stem. The correction can then be applied as a small percentage independently of the other corrections. The method of determining the fundamental interval above described applies to all other kinds of thermometers, except that it is not generally necessary to observe the zero after the steam point. The temperature of the steam t1 should be expressed in the scale of the thermometer tested, if the scale differs appreciably from that of Regnaut.

(III) Pressure Correction.—The corrections for variations of internal and external pressure on the bulb are of some importance in accurate thermometry, but can be applied with considerable certainty at moderate temperatures. The correction for external pressure is assumed to be proportional to the change of pressure, and to be independent of the temperature. It is generally determined by enclosing the thermometer to be tested in a vessel of water, and observing the change of reading on exhausting or readmitting the air. The correction is generally between one and two thousandths of a degree per centimetre of mercury change of pressure, but must be determined for each thermometer, as it depends on the nature of the glass and on the form and thickness of the walls of the bulb. The coefficient of the correction for internal pressure is greater than that for external pressure by the difference between the compressibility of mercury and that of glass, and may be calculated from it by assuming this relation. If b0, b1, are the external and internal coefficients, expressed in degrees of temperature per centimetre of mercury, we have the relation

| b1=b0+0·00015, degrees per cm. of mercury | (6) |

The coefficient of internal pressure can also be determined by taking readings in the horizontal and vertical positions when the thermometer is at some steady temperature such as that of ice or steam. The reading of the thermometer is generally reduced to an external pressure of one standard atmosphere, and to an internal pressure corresponding to the horizontal position. It is also. possible to include the internal pressure correction in the scale correction, if the thermometer is always read in the vertical position. In addition to the variations of internal pressure due to the column of mercury in the Stem, there are variations due to capillarity. The internal pressure is greater when the mercury is rising than when it is falling, and the reading is depressed to an extent depending on the fineness of the bore and the thinness of the walls of the bulb. The capillary pressure does not depend only on the bore of the tube, but also apparently to an even greater extent on the state of the walls of the tube. The least trace of dirt on the glass or on the mercury is capable of producing capillary pressures much greater than would be calculated from the diameter of the tube. Even in the best thermometers, when there are no inequalities of bore sufficient to account for the observed variations, it is seldom found that the mercury runs equally easily in all parts of the stem. These variations of capillary pressure are somewhat capricious, and set a limit to the order of accuracy attainable with the mercury thermometer. It appears that the difference of reading of a good thermometer between a rising and falling meniscus may amount to five or ten thousandths of a degree. The difference may be reduced by continuous tapping, but it is generally best to take readings always on a rising column, especially as the variations in the angle of contact, and therefore in the capillary pressure, appear to be much smaller for the rising meniscus. In ordinary work the zero reading and the steam reading would both generally correspond to a falling meniscus; the former necessarily, the latter on account of the phenomenon of the temporary depression of zero, which causes the thermometer to read higher during the first moments of its exposure to steam than it does when the expansion of the bulb has reached its limit. It is easy to secure a rising meniscus at the steam point by momentarily cooling the thermometer. At the zero point the meniscus generally begins to rise after five or ten minutes. The question, however, is not of much importance, as the error, if any, is regular, and the correction for capillarity is necessarily uncertain.

(IV) Stem-Exposure Correction.—When the bulb of a mercury thermometer is immersed in a bath at a temperature t, and a part of the column of mercury having a length of n degrees is exposed to a lower temperature t2, the reading of the thermometer will be lower by a✕n✕(t−t2) degrees (nearly) than it would have been if the whole of the mercury and stem had been at the temperature l. The factor a in this expression is the apparent coefficient of expansion of mercury in glass, and varies from ·000150 to ·000165 for different kinds of glass. In order to apply this correction, it is usual to observe t2 by means of an auxiliary “stem-thermometer” with its bulb placed near the middle of the emergent column n. Occasionally stem-thermometers with long thin bulbs are employed to give more nearly the average temperature of the whole emergent column. Owing to conduction along the stem of the thermometer, and to heated vapours near the bath, the mean temperature determined in this manner is generally too low. To allow for this empirically, an arbitrary reduction is often made in the value taken for n or a, but this cannot be regarded as satisfactory for work of precision. The only practical method of reducing the correction is to limit the number of degrees n exposed, or, in other words, to work with thermometers of “limited range.” Each of these thermometers must then be corrected by comparison with a standard thermometer free from stem-exposure correction, such as a platinum-resistance thermometer. To secure results of any value the correction must be determined at each point under the actual conditions of observation under which the thermometer is to be used. In work of precision it is necessary to use ten or twenty thermometers to cover a range of 300°, as this is the only method of securing an open scale and reasonable accuracy as regards stem-exposure. To quote the opinion of C. E. Guillaume, one of the leading authorities on mercurial thermometry: “When this correction is large, it cannot generally be determined with sufficient approximation for measurements of precision. The mercury thermometer should then be replaced by other instruments, among which those based on the variation of the electrical resistance of metals hold the first rank.”

(V) Scale Correction.—The correction required to reduce the readings of a mercurial thermometer to the normal scale may appropriately be called the “ scale correction.” One of the chief advantages of the mercurial thermometer for scientific purposes is that its scale agrees very closely with the thermodynamical scale between 0° and 200° C. The scale corrections of the standard French thermometers of verre dur have been very carefully determined over the range 0° to 80° C. by P. Chappuis using a constant volume gas thermometer containing hydrogen (at an initial pressure of one metre of mercury at 0° C.) as the representative of the normal scale. His observations between 0° and 80° C. are represented by the quartic equation

| th−tm = (−61·859+0·47351 t−0·0011577 t 2)✕10−6, | (7) |

in which th and tm represent temperature on the scales of the hydrogen and mercury thermometers respectively. The verre dur mercury thermometer reads 0·112° C. above the hydrogen thermometer at 40° C. where the difference of the scales is a maximum. The scale corrections of the Jena-glass thermometers, deduced by comparison with the French verre dur, appear to be practically of the same magnitude, but show differences of as much as 0·010° C. on either side of the mean. It may be questioned whether it is possible to construct mercury thermometers with scales agreeing more closely than this, owing to inevitable variations in the quality and treatment of the glass. According to Guillaume, the scale of a French cristal thermometer tc differs from that of the standard verre dur tm between 0° and 50° C., according to the cubic formula

| tc−tm = t(100−t)(14·126−0·03511t)✕10−6, | (8) |

According to some unpublished observations made by the writer in 1893–1894, the scale of an English flint-glass thermometer, tested by comparison with a platinum thermometer, does not differ from that of the constant-pressure air thermometer by more than one or two hundredths of a degree between 0° and 100° C. But for the comparison of the scales to be of any value, it would be necessary to study a large number of such thermometers. It is possible to obtain much more consistent results if the thermometers are not heated above 50° C.

The comparisons of the verre dur thermometers with the normal scale at the International Bureau at Paris have not as yet extended beyond 100° C. The most important observations on the mercury thermometer above these limits appear to be those of Regnault. The later observations of J. M. Crafts were confined to French thermometers of cristal dur (Comptes Rendus, 1882, 95, p. 863). He found the following deviations from the hydrogen scale:—

| th | 150° | 170° | 200° | 230° | 250° | 280° | 300° | 330° |

| th−tm | +·25 | +·35 | +·27 | −·02 | −·26 | −·63 | −1·21 | −2·48 |

The correction changes sign at about 230° C., owing to the rapid increase in the expansion of mercury. Between 0° and 150° C. it would appear that the coefficient of expansion of glass increases more rapidly than that of mercury.

Poggendorff’s Correction.—It should be observed that, since in the construction of a mercury thermometer the tube is divided or calibrated so as to read in divisions of equal volume when the whole of the tube is at one temperature, the degrees do not as a matter of fact correspond to equal increments of the apparent expansion of mercury. The scale does not therefore agree in practice with the theoretical formula (1) for the scale of the expansion of mercury, since the expansion is measured in a tube which itself is expanding. A similar argument applies to the method of the weight thermometer, in which the overflow-is measured by weight. Even if the expansion of mercury and glass were both uniform, as measured on the thermodynamical scale, the scale of the mercury thermometer, as ordinarily calibrated, would not agree with the thermodynamical scale. The difference can be easily calculated if the actual expansion of mercury and glass is known. The correction is known as Poggendorff's, but is generally included in the scale correction, and is not applied separately. It has the effect of making the thermometer read higher at temperatures between 0° and 100° than it would if the divisions of the stem did not expand as the temperature rose. The amount of the correction for verre dur is given by Guillaume as

| P.C.=t(100−t)(23·920+0·0240t)✕10−6 | (9) |

The value of this correction is between ·060° and ·080° at 50° C. for different thermometers.

|

| Fig. 2.—Differences between Scales of Mercury, and Gas Thermometers and Hydrogen Scale, according to Guillaume and Chappuis. |

Gas Thermometry

8. The deviations of the gas thermometer from the absolute scale are so small that this instrument is now universally regarded as the ultimate standard in thermometry. It had, in fact, already been adopted for this purpose by Regnault and others, on a priori considerations, before the absolute scale itself had been invented. Although the indications of a gas thermometer are not absolutely independent of the changes of volume of the envelope or bulb in which the gas is contained, the effect of any uncertainty in this respect is minimized by the relatively large expansibility of the gas. The capricious changes of volume of the bulb, which are so great a difficulty in mercurial thermometry, are twenty times less important in the case of the gas thermometer. As additional reasons for the choice we have the great simplicity of the laws of gases, and the approximate equality of expansion and close agreement of the thermometric scales of all gases, provided that they are above their critical temperatures. Subject to this condition, at moderate pressures and provided that they are not dissociated or decomposed, all gases satisfy approximately the laws of Boyle and Charles. These two laws are combined in the characteristic equation of the gaseous state, viz., pv=RT, in which p is the pressure and v the volume of unit mass of the gas in question, and R is a constant which varies inversely as the molecular weight of the gas, and is approximately equal to the difference of the specific heats.

9. Practical Conditions.—In practice it is not convenient to deal with unit mass, but with an arbitrary mass M occupying a space V, so that the specific volume v=V/M. It is also necessary to measure the pressure p in terms of mercury columns, and not in absolute units. The numerical value of the constant R is adjusted to suit these conditions, but is of no consequence in thermometry, as we are concerned with ratios and differences only. The equation may be written in the form T=pV/RM, but in order to satisfy the essential condition that T shall be a definite function of the temperature in the case of a gas which does not satisfy Boyle's law exactly, it is necessary to limit the application of the equation to special cases which lead to definite, but not necessarily identical, thermometric scales. There are three special cases of practical importance, corresponding to three essentially distinct experimental methods.

(i.) Volumetric Method (constant-pressure).—In this method V is variable and p and M are constant. This method was employed by Gay-Lussac, and is typified in the ideal thermometer with reservoir of variable capacity designed by Lord Kelvin (Ency. Brit., ed. ix., vol. xi. p. 575, fig. 10). It corresponds to the method ordinarily employed in the common liquid-in-glass thermometer, but is not satisfactory in practice, owing to the difficulty of making a bulb of variable and measurable volume the whole of which can be exposed to the temperature to be measured.

(ii.) Manometric Method (constant-volume or density).—In this method p is variable and V and M are constant. Variations of temperature are observed and measured by observing the corresponding variations of pressure with a mercury manometer, keeping a constant mass, M, of gas enclosed in a volume, V, which is constant except for the unavoidable but small expansion of the material of which the bulb is made.

(iii.) Gravimetric Method (constant-pressure).—In this method M is variable and p and V are constant. This method is generally confounded with (i.) under the name of the constant pressure method, but it really corresponds to the method of the weight thermometer, or the “overflow” method, and is quite distinct from an experimental standpoint, although it leads to the same thermometric scale. In applying this method, the weight M of the vapour itself may be measured, as in Regnault's mercury-vapour thermometer, or in Deville and Troost's iodine-vapour thermometer. The best method of measuring the overflow is that of weighing mercury displaced by the gas. The mass of the overflow may also be estimated by observing its volume in a graduated tube. but this method is much less accurate.

In addition to the above, there are mixed methods in which both p and V or M are variable, such as those employed by Rudberg or Becquerel; but these are unsatisfactory for precision, as not leading to a sufficiently definite thermometric scale. There is also a variation of the constant-volume method (ii.), in which the pressure is measured by the volumetric compression of an equal mass of gas kept at constant temperature, instead of by a manometer. This method is experimentally similar to (iii.), and gives the same equations, but a different thermometric scale from either (ii.) or (iii.). It will be considered with method (iii.), as the apparatus required is the same, and it is useful for testing the theory of the instrument. We shall consider in detail methods (ii.) and (iii.) only, as they are the most important for accurate work.

10. Construction of Apparatus.—The manometric or constant-volume method was selected by Regnault as the standard, and has been most generally adopted since his time. His apparatus has not been modified except in points of detail. A description of his instrument will be found in most text-books on heat. A simple and convenient form of the instrument for general use is Jolly's (described in Poggendorff's Jubelband, p. 82, 1874), and represented in fig. 3. The two vertical tubes of the manometer are connected by an india-rubber tube properly strengthened by a cotton covering, and they can be made to slide vertically up and down a wooden pillar which supports them; they are provided with clamps for fixing them in any position and a tangent screw for fine adjustment. The connexion between the bulb and the manometer is made by means of a three-way tap. The scale of the instrument is engraved on the back of a strip of plane mirror before silvering, and the divisions are carried sufficiently far across the scale for the reflections of the two surfaces of the mercury to be visible behind the, scale. Parallax can thus be avoided and an accurate reading obtained without the necessity of using a cathetometer. In order to allow for the expansion of the glass of the reservoir a weight-thermometer bulb is supplied with the instrument, made from another specimen of the same kind of glass, and the relative expansion of the mercury and the glass can thus be determined by the observer himself. The volume of the air-bulb and that of the capillary tube and the small portion of the manometer tube above the small beak of glass, the point of which serves as the fiducial mark, are determined by the

instrument makers. The improvements introduced by Chappuis, of the International Bereau at sèvres, in construction of the constant-volume hydrogen thermometer selected by the committee for the determination of the normal scale, are described in the text-books (e.g. Watson's Physics); The most important is the

|

| Fig. 3. |

combination of the manometer and the barometer into a single instrument with a single scale, thus reducing the number of readings required. The level of the mercury in the branch of the manometer communicating with the bulb of the gas thermometer is adjusted in the usual manner up to a fixed contact-point, so as to reduce the contained gas to a constant volume. Simultaneously the barometer branch of the manometer is adjusted so that the surface of the mercury makes Contact with another point fixed in the upper end of the barometer tube. The distance between two contact-points, giving the pressure of the gas in the thermometer, is deduced from the reading of a vernier fixed relatively to the upper contact-point. This method of reading the pressure is probably more accurate than the method of the cathetometer which is usually employed, but has the disadvantage of requiring a double adjustment.

11. Pressure Correction.—In the practical application of the manometric method there are certain corrections peculiar to the method, of which account must be taken in work of precision. The volume of the bulb is not accurately constant, but varies with change of pressure and temperature. The thermal expansion of the bulb is common to all methods, and will be considered in detail later. The pressure correction is small, and is determined in the same manner as for a mercury thermometer. The value so determined, however, does not apply strictly except at the temperature to which it refers. If the pressure-coefficient were constant at all temperatures and equal to e, the pressure correction, dt, at any point t of the scale would be obtainable from the simple formula

| dt=ep₀t(t-100)/T₀ | (10) |

where p₀ is the initial pressure at the temperature T₀. But as the coefficient probably varies in an unknown manner, the correction is somewhat uncertain, especially at high temperatures. Another very necessary but somewhat troublesome correction is the reduction of the manometer readings to allow for the varying temperatures of the mercury and scale. Since it is generally impracticable to immerse the manometer in a liquid bath to secure certainty and uniformity of temperature, the temperature must be estimated from the readings of mercury thermometers suspended in mercury tubes or in the air near the manometer. It is therefore necessary to work in a room specially designed to secure great constancy of temperature, and to screen the manometer with the utmost care from the source of heat in measurements of high temperature. Regnault considered that the limit of accuracy of correction was one-tenth of a millimetre of mercury, but it is probably possible to measure to one-hundredth as a mean of several readings under the best conditions, at ordinary temperatures.

12. Stem-Exposure.—In all gas thermometers it is necessary in practice that the part of the gas in contact with the mercury or other liquid in the manometer should not be heated, but kept at a nearly constant temperature. The space above the mercury, together with the exposed portion of the capillary tube connecting the manometer with the thermometric bulb, may be called the “dead space.” If the volume of the dead space is kept as nearly as possible constant by adjusting the mercury always up to a fixed mark, the quantity of air in this space varies nearly in direct proportion to the pressure, i.e. in proportion to the temperature of the thermometric bulb at constant volume. This necessitates the application of a stem-exposure correction, the value of which is approximately given by the formula

| dt=rt(t−100)/T2, | (11) |

where r is the ratio of the volume of the dead space to the volume of the thermometric bulb, and T2 is the mean temperature of the dead space, which is supposed to be constant. The magnitude of the correction is proportional to the ratio r, and increases very rapidly at high temperatures. If the dead space is 1 per cent. of the bulb, the correction will amount to only one-tenth of a degree at 50° C., but reaches 5 ° at 445 °C., and 30° at 1000 °C. It is for this reason important in high-temperature work to keep the dead space as small as possible and to know its volume accurately. With a mercury manometer, the volume is liable to a slight uncertainty on account of changes of shape in the meniscus, as it is necessary to use a wide tube in order to secure accurate measurements of pressure.

|

| Fig. 4.—Method of Compensation. |

13. Compensation Method with Oil-Gauge.—It is possible to avoid this difficulty, and to make the dead space very small, by employing oil or sulphuric acid or other non-volatile liquid to confine the gas in place of mercury (Phil. Trans., A. 1887, p. 171). The employment of a liquid which wets the tube makes it possible to use a much smaller bore, and also greatly facilitates the reading of small changes of pressure. At the same time the instrument may be arranged so that the dead space correction is automatically eliminated with much greater accuracy than it can be calculated. This is effected as shown diagrammatically in fig. 4, by placing side by side with the tube AB, connecting the bulb B to the manometer A, an exact duplicate CD, closed at the end D, and containing liquid in the limb C, which is of the same size as the branch A of the manometer and in direct communication with it. The tube CD, which is called the compensating tube, contains a constant mass of gas under exactly similar conditions of volume and temperature to the tube AB. If therefore the level of the liquid is always adjusted to be the same in both tubes AB and CD, the mass of gas contained in the dead space AB will also be constant, and is automatically eliminated from the equations, as they contain differences only.

14. Gravimetric Method.—In the writer's opinion, the gravimetric or overflow method, although it has seldom been adopted, and is not generally regarded as the most accurate, is much to be preferred to the manometric method, especially for work at high temperatures. It is free from the uncertain corrections above enumerated as being peculiar to the manometric method. The apparatus is much simpler to manipulate and less costly to construct. If the pressure is kept constant and equal to the external atmospheric pressure, there is no strain of the bulb, which is particularly important at high temperatures. There is no dead space correction so long as the temperature of the dead space is kept constant. The troublesome operation of reading and adjusting the mercury columns of the manometer is replaced by the simpler and more accurate operation of weighing the mercury displaced, which can be performed at leisure. The uncertain correction for the temperature of the mercury in the manometer is entirely avoided.

The reasons which led Regnault to prefer the constant-volume thermometer are frequently quoted, and are generally accepted as entirely conclusive, but it is very easy to construct the constant-pressure or gravimetric instrument in such a manner as to escape the objections which he urges against it. Briefly stated, his objections are as follows: (1) Any error in the observation of the temperature of the gas in the overflow space produces a considerable error in the temperature deduced, when the volume of the overflow is large. This source of error is very simply avoided by keeping the whole of the overflow in melting ice, an expedient which also considerably simplifies the equations. It happened that Regnault’s form of thermometer could not be treated in this manner, because he had to observe the level of the mercury in order to measure. the pressure and the volume. It is much better, however, to use a separate gauge, containing oil or sulphuric acid, for observing small changes of pressure. The use of ice also eliminates the correction for the variation of density of the mercury by which the overflow is measured. (2) Regnault's second objection was that an error in the measurement of the pressure, or in reading the barometer, was more serious at high temperatures in the case of the constant-pressure thermometer than in the constant-volume method. Owing to the incessant variations in the pressure of the atmosphere, and in the temperature of the mercury columns, he did not feel able to rely on the pressure readings (depending on observations of four mercury surfaces with the cathetometer) to less than a tenth of a millimetre of mercury, which experience showed to be about the limit of accuracy of his observations. This would be equivalent to an error of 0·036° with the constant-volume thermometer at any point of the scale, but with the constant-pressure thermometer the error would be larger at higher temperatures, since the pressure does not increase in proportion to the temperature. This objection is really unsound, because the ideal condition to be aimed at is to keep the proportionate error dT/T constant. That the proportionate error diminishes with rise of temperature, in the case of the constant-volume thermometer, is really of no advantage, because we can never hope to be able to measure high temperatures with greater proportionate accuracy than ordinary temperatures. The great increase of pressure at high temperatures in the manometric method is really a serious disadvantage, because it becomes necessary to work with much lower initial pressures, which implies inferior accuracy at ordinary temperatures and in the determination of the initial pressure and the fundamental interval.

15. Compensated Differential Gas Thermometer.—The chief advantage of the gravimetric method, which Regnault and others appear to have missed, is that it is possible to make the measurements altogether independent of the atmospheric pressure and of the observation of mercury columns. This is accomplished by using, as a standard of constant pressure, a bulb S, fig. 5, containing a constant mass of gas in melting ice, side by side with the bulb M, in which the volume of the overflow is measured. The pressure in the thermometric bulb T is adjusted to equality with the standard by means of a delicate oil-gauge G of small bore, in which the difference of pressure is observed by means of a cathetometer microscope. This kind of gauge permits the rapid observation of small changes of pressure, and is far more accurate and delicate than the mercury manometer. The fundamental measurement of the volume of the overflow in terms of the weight of mercury displaced at 0°C. involves a single weighing made at leisure, and requires no temperature correction. The accuracy obtainable at ordinary temperatures in this measurement is about ten times as great as that attainable under the best conditions with the mercury manometer. At higher temperatures the relative accuracy diminishes in proportion to the absolute temperature, or the error dt increases according to the formula

| dt/t =− (T/T0) dw/w, | (12) |

where w is the weight of the overflow and dw the error. This diminution of the sensitiveness of the method at high temperatures is commonly urged as a serious objection to the method, but the objection is really without weight in practice, as the possible accuracy of measurement is' limited by other conditions. So far as the weighing alone is concerned, the method is sensitive to one-hundredth of a degree at 1000°C., which is far beyond the order of accuracy attainable in the application of the other corrections.

16. Method of Using the Instrument.—A form of gas thermometer constructed' on the principles above laid down, with the addition of a duplicate set of connecting tubes C for the elimination of the stem-exposure correction by the method of automatic compensation already explained, is shown in fig. 5 (Proc. R. S. vol. 50, p. 243; Preston's Heat, p. 133).

In setting up the instrument, after cleaning, and drying and calibrating the bulbs and connecting tubes, the masses of gas on the two sides are adjusted as nearly as possible to equality, in order that any changes of temperature in the two sets of connecting tubes may compensate each other. This is effected with all the bulbs in melting ice, by adjusting the quantities of mercury in the bulbs M and S and equalizing the pressures. The bulb T is then heated in steam to determine the fundamental interval. A weight w1 of mercury is removed from the overflow bulb M in order to equalize the pressures again. If W is the weight of the mercury at 0°C which would be required to fill the bulb T at 0°C., and if W+dW1 is the weight of mercury at 0° which would be required to fill a volume equal to that of the bulb in steam at t1, we have the following equation for determining the coefficient of expansion a, or the fundamental zero Tₒ,

| at1=t1/T0=(w1+dW1)/(W−w1), | (13) |

Similarly if w is the overfiow when the bulb is at any other temperature t, and the expansion of the bulb is dW, we have a precisely similar equation for determining t in terms of T0, but with t and w and dW substituted for t1 and w1 and d/W1. In practice, if the pressures are not adjusted to exact equality, or if the volumes of

| |

| Fig. 5.—Compensated Differential Gas Thermometer. |

the connecting tubes do not exactly compensate, it is only necessary to include in w a small correction dw, equivalent to the observed difference, which need never exceed one part in ten thousand.

It is possible to employ the same apparatus at constant volume as well as at constant pressure, but the manipulation is not quite so simple, in consequence of the change of pressure. Instead of removing mercury from the overflow bulb M in Connexion with the thermometric bulb, mercury is introduced from a higher level into the standard bulb S so as to raise its pressure to equality with that of T at constant volume. The equations of this method are precisely the same as those already given, except that; w now signifies the* “inflow” weight introduced into the bulb S, instead of the overflow weight from M. It is necessary, however, to take account of the pressure-coefficient of the bulb T, and it is much more important to have the masses of gas on the two sides of the apparatus equal than in the other case. The thermometric scale obtained in this method differs slightly from the scale of the manometric method, on account of the deviation of the gas compressed at o°C. from Boyle's law, but it is easy to take account of this with certainty.

Another use to which the same apparatus may be put is the accurate comparison of the scales of two different gases at constant volume by a differential method. It is usual to effect this comparison indirectly, by comparing the gas thermometers separately with a mercury thermometer, or other secondary standard. But by using a pair of bulbs like M and S simultaneously in the same bath, and measuring the small difference of pressure with an oilgauge, a higher order of accuracy may be attained in the measurement of the small differences than by the method of indirect comparison. For instance, in the curves representing the difference between the nitrogen and hydrogen scales (fig. 1), as found by Chappuis by comparison of the nitrogen and hydrogen thermometers with the mercury thermometer, it is probable that the contrary flexure of the curve between 70° and 100° C. is due to a minute error of observation, which is quite as likely to be caused by the increasing aberrations of the mercury thermometer at these temperatures as by the difficulties of the manometric method. It may be taken as an axiom in all such cases that it is better to measure the small difference itself directly than to deduce it from the much more laborious observations of the separate magnitudes concerned.

17. Expansion Correction.—In the use of the mercury thermometer we are content to overlook the modification of the scale due to the expansion of the envelope, which is known as Poggendorff's correction, or rather to include it in the scale correction. In the case of the gas thermometer it is necessary to determine the expansion correction separately, as our object is to arrive at the closest approximation possible to the absolute scale. It is a common mistake to imagine that if the rate of expansion' of the bulb were uniform, the scale of the apparent expansion of the gas would be the same as the scale of the real expansion—in other words, that the correction for the expansion of the bulb would affect the value of the coefficient of expansion 1/T0 only, and would be without effect on the value of the temperature t deduced. A result of this kind would be produced by a constant error in the initial pressure on the manometric method, or by a constant error in the initial volume on the volumetric method, or by a constant error in the fundamental interval on any method, but not by a constant error in the coefficient of expansion of the bulb, which would produce a modification of the scale exactly analogous to Poggendorff’s, correction. The correction to be applied to the value of t in any case to allow for any systematic error or variation in the data is easily found by differentiating the formula for t with respect to the variable considered. Another method, which is in some respects more instructive, is the following:—

Let T be the function of the temperature which is taken as the basis of the scale considered, then we have the value of t given by the general formula (1), already quoted in § 3. Let dT be the correction to be added to the observed value of T to allow for any systematic change or error in the measurement of any of the data on which the value of T depends, and let dt be the corresponding correction produced in the value of t, then substituting in formula (1) we have,

| t+dt=100(T−Tₒ+dT−dTₒ)/(T1−Tₒ+dT1−dT0), |

from which, provided that the variations considered are small, we obtain the following general expression for the correction to t,

| dt=(dT −dTₒ) − (dT1 − dT0)t/ 100. | (14) |

It is frequently simpler to estimate the correction in this manner, rather than by differentiating the general formula.

In the special case of the gas thermometer the value of T is given by the formula

| T=pV/RM=pV/R(M0−M2), | (15) |

where p is the observed pressure at any temperature t, V the volume of the thermometric bulb, and M the mass of gas remaining in the bulb. The quantity M cannot be directly observed, but is deduced by subtracting from the whole mass of gas M0 contained in the apparatus the mass M2 which is contained in the dead space and overflow bulb. In applying these formulae to deduce the effect of the expansion of the bulb, we observe that if dV is the expansion from 0°C., and V0, the volume at 0°C., we may write

| V=Vₒ+dV, T=p(Vₒ+dV)/RM=(pV0/RM)(1+dV/V0), |

whence we obtain approximately

| dT=TdV/Vₒ | (16) |

If the coefficient of expansion of the bulb is constant and equal to the fundamental coefficient f (the mean coefficient between 0° and 100° C.), we have simply dV/V0=ft; and if we substitute this value in the general expression (14) for dt, we obtain

| dt=(T−T1)ft=ft(t−100) | (17) |

Provided that the correction can be expressed as a rational integral function of t, it is evident that it must contain the factor stand (t−100), since by hypothesis the scale must be correct at the fixed points 0° and 100°C., and the correction must vanish at these points. It is clear from the above that the scale of the gas thermometer is not independent of the expansion of the bulb even in the simple case where the coefficient is constant. The correction is by no means unimportant. In the case of an average glass or platinum reservoir, for which f may be taken as 0·000025 nearly, the correction amounts to −0·0625° at 50° C., to 3·83° at 445° C., and to 22·5° at 1000° C.

The value of the fundamental coefficient f can be determined with much greater accuracy than the coefficient over any other range of temperature. The most satisfactory method is to use the bulb itself as a mercury weight thermometer, and deduce the cubical expansion of the glass from the absolute expansion of mercury as determined by Regnault. Unfortunately the reductions of Regnault’s observations by different calculators differ considerably even for the fundamental interval. The values of the fundamental coefficient range from ·00018153 Regnault, and ·00018210 Broch, to ·00018253 Wüllner. The extreme difference represents an uncertainty of about 4 per cent. (1 in 25) in the expansion of the glass. This uncertainty is about 100 times as great as the probable error of the weight thermometer observations. But the expansion is even less certain beyond the limits of the fundamental interval. Another method of determining the expansion of the bulb is to observe the linear expansion of a tube or rod of the same material, and deduce the cubical expansion on the assumption that the expansion is isotropic. It is probable that the uncertainty involved in this assumption is greater in the case of glass or porcelain bulbs, on account of the difficulty of perfect annealing, than in the case of metallic bulbs.

Except for small ranges of temperature, the assumption of a constant coefficient of expansion is not sufficiently exact. It is therefore usual to assume that the coefficient is a linear function of the temperature, so that the whole expansion from 0° C. may be expressed in the form d V=t(a+bt)V0, in which case the fundamental coefficient f=a+100b. Making this substitution in the formula already given, we obtain the whole correction

| dt=(f+bT)t(t−100) | (18) |

It will be observed that the term involving b becomes of considerable importance at high temperatures. Unfortunately, it cannot be determined with the same accuracy as f, because the conditions of observation at the fixed points are much more perfect than at other temperatures. Provided that the range of the observations for the determination of the expansion is co-extensive with the range of the temperature measurements for which the correction is required, the uncertainty of the correction will not greatly exceed that of the expansion observed at any point of the range. It is not unusual, however, to deduce the values of b and f from observations confined to the range 0° to 100° C., in which case an error of 1 per cent., in the observed expansion at 50° C., would mean an error of 60 per cent. at 445°, or of 360 per cent. at 1000° C. (Callendar, Phil. Mag. December 1899). Moreover, it by no means follows that the average value of b between 0° and 100° C. should be the same as at higher or lower temperatures. The method of extrapolation would therefore probably lead to erroneous results in many cases, even if the value could be determined with absolute precision over the fundamental interval. It is probable that this expansion correction, which cannot be reduced or eliminated like many of the other corrections which have been mentioned, is the chief source of uncertainty in the realization of the absolute scale of temperature at the present time. The uncertainty is of the order of one part in five or ten thousand on the fundamental interval, but may reach 0·5° at 500° C., and 2° or 3° at 1000° C.

18. Thermodynamical Correction.—Of greater theoretical interest, but of less practical importance on account of its smallness, is the reduction of the scale of the gas thermometer to the thermodynamical scale. The deviations of a gas from the ideal equation pv=Rθ may be tested by a variety of different methods, which should be employed in combination to determine the form of the characteristic equation. The principal methods by which the problem has been attacked are the following:—

(1) By the comparison of gas thermometers filled with different gases or with the same gas at different pressures (employing both gravimetric and manometric methods) the differences in their indications are observed through as wide a range of temperature as possible. Regnault, employing this method, found that the differences in the scales of the permanent gases were so small as to be beyond the limits of accuracy of his observations. Applying greater refinements of measurement, Chappuis and others have succeeded in measuring small differences, which have an important bearing on the type of the characteristic equation. They show, for instance, that the equation of van der Waals, according to which all manometric gas thermometers should agree exactly in their indications, requires modification to enable it to represent the behaviour of gases even at moderate pressures.

(2) By measuring the pressure and expansion coefficients of different gases between 0° and 100° C. the values of the fundamental zero (the reciprocal of the coefficient of expansion or pressure) for each gas under different conditions may be observed and compared. The evidence goes to show that the values of the fundamental zero for all gases tend to the same limit, namely, the absolute zero, when the pressures are indefinitely reduced. The type of characteristic equation adopted must be capable of representing the variations of these coefficients.

(3) By observing the variations of the product pv with pressure at constant temperature the deviations of different gases from Boyle’s law are determined. Experiment shows that the rate of change of the product pv with increase of pressure, namely d(pv)/dp, is very nearly constant for moderate pressures such as those employed in gas thermometry. This implies that the characteristic equation must be of the type

| v=F(θ)/P+f(θ) | (19) |

in which F(θ) and f(θ) are functions of the temperature only to a first approximation at moderate pressures. The function F(θ), representing the limiting value of pv at zero pressure, appears to be simply proportional to the absolute temperature for all gases. The function f(θ), representing the defect of volume from the ideal volume, is the slope of the tangent at p=0 to the isothermal of θ on the pv,p diagram, and is sometimes called the “angular coefficient.” It appears to be of the form b−c, in which b is a small constant quantity, the “co-volume,” of the same order of magnitude as the volume of the liquid, and c depends on the cohesion or co-aggregation of the molecules, and diminishes for all gases continuously and indefinitely with rise of temperature. This method of investigation has been very widely adopted, especially at high pressures, but is open to the objection that the quantity b−c is a very small fraction of the ideal volume in the case of the permanent gases at moderate pressures, and its limiting value at p=0 is therefore difficult to determine accurately.

(4) By observing the cooling effect dθ/dp, or the ratio of the fall of temperature to the fall of pressure under conditions of constant total heat, when a gas flows steadily through a porous plug, it is possible to determine the variation of the total heat with pressure from the relation

| Sdθ/dp=θdv/dθ−v | (20) |

(See Thermodynamics, § 10, equation 15.) This method has the advantage of directly measuring the deviations from the ideal state, since θdv/dθ=v for an ideal gas, and the cooling effect vanishes. But the method is difficult to carry out, and has seldom been applied. Taken in conjunction with method (3), the observation of the cooling effect at different temperatures affords most valuable evidence with regard to the variation of the defect of volume c−b from the ideal state. The formula assumed to represent the variations of c with temperature must be such as to satisfy both the observations on the compressibility and those on the cooling effect. It is possible, for instance, to choose the constants in van der Waals’s formula to satisfy either (3) or (4) separately within the limits of experimental error, but they cannot be chosen so as to satisfy both. The simplest assumption to make with regard to c is that it varies inversely as some power n of the absolute temperature, or that c = c0(θ0/θ)n, where c0 is the value of c at the temperature θ0. In this case the expression θdv/dθ−v takes the simple form (n+1)c−b. The values of n, c and b could be calculated from observations of the cooling effect Sdθ/dp alone over a sufficient range of temperature, but, owing to the margin of experimental error and the paucity of observations available, it is better to make use of the observations on the compressibility in addition to those on the cooling effect. It is preferable to calculate the values of c and b directly from equation (20), in place of attempting to integrate the equation according to Kelvin’s method (Ency. Brit. ed. ix. vol. xi. p. 573), because it is then easy to take account of the variation of the specific heat S, which is sometimes important.

Calculation of the Correction.—Having found the most probable values of the quantities c, b and n, from the experimental data, the calculation of the correction may be very simply effected as follows: The temperature by gas thermometer is defined by the relation T=pv/R, where the constant R is determined from the observations at 0° and 100° C. The characteristic equation in terms of absolute temperature θ may be put in the form θ=pv/R′+q, where q is a small quantity of the same dimensions as temperature, given by the relation

| q=(c−b)p/R | (21) |

The constant R′ is determined, as before, by reference to the fundamental interval, which gives the relation R′/R=1+(q1−q0)/100, where q1 and q0 are the values of q at 100° and 0° C. respectively.

The correction to be added to the fundamental zero T0 of the gas thermometer in order to deduce the value of the absolute zero θ0 (the absolute temperature corresponding to 0° C.) is given by the equation,

| θ0−T0=q0−(q1−q0)θ0/100 | (22) |

The correction dt to be added to the centigrade temperature t by gas thermometer reckoned from 0° C. in order to deduce the corresponding value of the absolute temperature also reckoned from 0° C. is given by the relation, deduced from formula (14),

| dt=(q−q0)−(q1−q0)t/100 | (23) |

where q is the value at t ° C. of the deviation (c−b)p/R. The formulae may be further simplified if the index n is a simple integer such as 1 or 2. The values of the corrections for any given gas at different initial pressures are directly proportional to the pressure. Values of the Corrections.—If we take for the gas hydrogen the values c=1·5 c.c. at 0° C., b=8·0 c.c., with the index n=1·5, which satisfy the observations of Joule and Thomson on the cooling effect, and those of Regnault, Amagat and Chappuis on the compressibility, the values of the absolute zero θ0, calculated from Chappuis’s values of the pressure and expansion coefficients at 100 cms. initial pressure, are found to be 273·10° and 273·05° respectively, the reciprocals of the coefficients themselves being 273·03 and 273·22. The corrections are small and of opposite signs. For nitrogen, taking c0=1·58, b=1·14, n=1·5, we find similarly 273·10° and 273·13° for the absolute zero, the correction θ0–T0 in this case amounting to nearly 1°. The agreement is very good consider in the difficulty of determining the small deviations c and b, and the possible errors of the expansion and pressure-coefficients. It appears certain that the value of the absolute zero is within a few hundredths of a degree of 273·10°. Other observations confirm this result within the limits of experimental error. The value of the index n has generally been taken as equal to 2 for diatomic gases, but this does not satisfy either the observations on the cooling effect or those on the compressibility so well as n=1·5, although it makes comparatively little difference to the value of the absolute zero. The value deduced from Travers’s observation of the pressure-coefficient of helium is 273·13°, taking n=12, which is the probable value of the index for a monatomic gas. The application of the method to the condensible gas carbonic acid is interesting as a test of the method (although the gas itself is not suited for thermometry), because its deviations from the ideal state are so large and have been so carefully studied. The observations of Joule and Thomson on the cooling effect give c0=3·76 c.c., b=0·58 c.c., n=2, provided that allowance is made for the variation of the specific heat with temperature as determined by Regnault and Wiedemann. Chappuis’s values of the pressure and expansion coefficients agree in giving 273·05° for the absolute zero, the values of the corrections θ0–T0 being 4·6° and 5·8° respectively.

The values of the scale correction dt deduced from these formulae agree with those experimentally determined by Chappuis in the case of carbonic acid within the limits of agreement of the observations themselves. The calculated values for nitrogen and hydrogen give rather smaller differences than those found experimentally, but the differences themselves are of the same order as the experimental errors. The deviations of hydrogen and helium from the absolute scale between 0° and 100° C. are of the order of ·001° only, and beyond the limits of accuracy of experiment. Even at −250° C. (near the boiling-point of hydrogen) the corrections of the constant volume hydrogen and helium thermometers are only a tenth of a degree, but, as they are of opposite signs, the difference amounts to one-fifth of a degree at this point, which agrees approximately with that observed by Travers. For a fuller discussion of the subject, together with tables of corrections, the reader may refer to papers by Callendar, Phil. Mag. v. p. 48 (1903). and D. Berthelot, Trav. et Mém. Bur. Int. Paris, xiii. (1903). Berthelot assumes a similar type of equation to that given above, but takes n=2 in all cases, following the so-called law of corresponding states. This assumption is of doubtful validity, and might give rise to relatively large errors in the case of monatornic gases.

19. Limitations.—In the application of the gas thermometer to the measurement of high temperatures certain difficulties are encountered which materially limit the range of measurement and the degree of accuracy attainable. These may be roughly classified under the heads—(1) changes in the volume of the bulb; (2) leakage, occlusion and porosity; (3) chemical Change and dissociation. The difficulties arise partly from defects in the materials available for the bulb, and partly from the small mass of gas enclosed. The troubles due to irregular changes of volume of glass bulbs, which affect the mercury thermometer at ordinary temperatures, become so exaggerated at higher points of the scale as to be a serious source of trouble in gas thermometry in spite of the twenty fold larger expansion. For instance, the volume of a glass bulb will be diminished by from one-quarter to one-half of 1 per cent. the first time it is heated to the temperature of boiling sulphur (445° C.). This would not matter so much if the volume then remained constant. Unfortunately, the volume continues to change, especially in the case of hard glass, each time it is heated, by amounts which cannot be predicted, and which are too large to neglect. The most accurate method of taking account of these variations in a series of observations, without recalibrating and refilling and cleaning the bulb, is to assume the known constant value of the coefficient of expansion of the gas, and to calculate the volume of the bulb at any time by taking observations in icei and steam (Phil. Trans. A. 1891, vol. 182, p. 124). Similar changes take place with porcelain at higher temperatures. Metallic bulbs are far more perfect than glass bulbs in this respect. It is probable that silica bulbs would be the most perfect. The writer suggested the use of this material (in the Journ. Iron and Steel Inst. for 1892), but failed to construct bulbs of sufficient size. W. A. Shenstone, however, subsequently succeeded, and there seems to be a good prospect that this difficulty will soon be minimized. The difficulties of leakage and porosity occur chiefly with porcelain bulbs, especially if they are not perfectly glazed inside. A similar difficulty occurs with metallic bulbs of platinum or platinum-iridium, in the case of hydrogen, which passes freely through the metal by occlusion at high temperatures. The difficulty can be avoided by substituting either nitrogen or preferably argon or helium as the thermometric material at high temperatures. With many kinds of glass and porcelain the chemical action of hydrogen begins to be appreciable at temperatures as low as 200° or 300° C. In any case, if metallic bulbs are used, it is absolutely necessary to protect them from furnace gases which may contain hydrogen. This can be effected either by enclosing the bulb in a tube of porcelain, or by using some method of electric heating which cannot give rise to the presence of hydrogen. At very high temperatures it is probable that the dissociation of diatomic gases like nitrogen might begin to be appreciable before the limit of resistance of the bulb itself was reached. It would probably be better, for this reason, to use the monatomic and extremely inert gases argon or helium.

20. Other Methods.—Many attempts have been made to overcome the difficulties of gas pyrometry by adopting other methods of measurement. Among the most interesting may be mentioned: (i.) The variation in the wave-length of sound. The objection to this method is the difficulty of accurately observing the wave-length, and of correcting for the expansion of the material of the tubes in which it is measured. There is the further objection that the velocity varies as the square root of the absolute temperature. (ii.) A similar method, but more promising, is the variation of the refractivity of a gas, which can be measured with great accuracy by an interference method. Here again there is difficulty in determining the exact length of the heated column of gas, and in maintaining the temperature uniform throughout a. long column at high temperatures. These difficulties have been ingeniously met by D. Berthelot (Comptes Rendus, 1895, 120, p. 831). But the method is not easy to apply, and the degree of accuracy attainable is probably inferior to the bulb methods. (iii.) Methods depending on the effusion and transpiration of gases through fine orifices and tubes have been put in practice by Barus and by the writer. The method of transpiration, when the resistance of the tube through which the current of gas is passed is measured on the Wheatstone bridge principle (Nature, 23rd March 1899), is extremely delicate, and the apparatus may be made very small and sensitive, but the method cannot be used for extrapolation at high temperatures until the law of increase of resistance has been determined with certainty. This may be successfully accomplished in the near future, but the law is apparently not so simple as is usually supposed.

On account of these and similar difficulties, the limit of gas thermometry at the present time must be placed at 1500° C., or even lower, and the accuracy with which temperatures near 1000° C. are known does not probably exceed 2° C. Although measurements can be effected with greater consistency than this by means of. electrical pyrometers, the absolute values corresponding to those temperatures must remain uncertain to this extent, inasmuch as they depend on observations made with the gas thermometer.

Electrical Thermometry

21. The convenience of the mercurial thermometer lies in the fact that it is complete in itself, and can be read without subsidiary appliances beyond a magnifying glass. Its weakness lies in the very limited range of each single instrument, and in the troublesome and often uncertain corrections which must be applied to its readings in all work of precision. Electrical thermometers have the disadvantage of requiring auxiliary apparatus, such as galvanometers and resistances, the use of which involves some electrical training. But they far surpass the mercurial thermometer in point of range, delicacy and adaptability, and can be applied to many investigations in which ordinary thermometers are quite useless.

There are two kinds of electrical thermometers, which depend on different effects of heat on the electrical properties of metals: (1) The Thermocouple, or Thermopile, which depends on the production of a thermoelectric force when the junctions of different metals in an electric circuit are at different temperatures; and (2) the Electrical Resistance Thermometer, the action of which depends on the fact that the resistance of a pure metal to the passage of an electric current increases very considerably when the temperature is raised. The theory of the thermocouple is discussed in the article Thermoelectricity, as it possesses many points of interest, and has been studied by many skilful experimentalists. The electrical resistance thermometer is of more recent origin; but although the theory has been less fully developed, the practice of the method bids fair to surpass all others in the variety and accuracy of its applications. In order to secure the widest possible range and the greatest constancy, in either variety of electrical thermometer, advantage is taken of the great stability and in fusibility characteristic of the metals of the platinum group. Other metals are occasionally used in work at low temperatures with thermocouples for the sake of obtaining a larger electromotive force, but the substitution is attended with loss of constancy and uncertainty of reduction, unless the range is greatly restricted.