A problem which has been exercising the minds of those engaged in submarine work is the greatest depth at which it is possible to work, for, as is well known, many a fine vessel with valuable cargo and treasure is lying out of reach of the diver owing to the pressure which he would have to sustain were he to attempt to reach her. Mr Leonard Hill, and Drs Greenwood and J. J. R. Macleod conducted experiments in conjunction with Messrs Siebe, Gorman & Co., with a view to solving this problem, and their efforts have been attended with some considerable success. Dr J. S. Haldane has also carried out practical experiments for the British Admiralty, and under his supervision two naval officers have succeeded in reaching the unprecedented depth of 210 ft., at which depth the pressure is about 90 ℔ to the square inch.

Diving Bells.—Every one is familiar with the experiment of placing an inverted tumbler in a bowl of water, and seeing the water excluded from the tumbler by the air inside it. Perhaps it was to some such experiment as this that the conception of the diving bell was due. As is well known, the pressure of water increases with the depth, and for all practical purposes this pressure can be taken at 414 ℔ to every 10 ft. The following table shows the pressure at different depths below the surface of the water:—

| Depth. | Pressure. |

| 20 ft. | 812 lb to the sq. in. |

| 40 ” | 1714 ” ” |

| 80 ” | 3434 ” ” |

| 120 ” | 5212 ” ” |

| 160 ” | 6934 ” ” |

| 200 ” | 87 ” ” |

If a diving bell be sunk to a depth of, say, 33 ft., the air inside it will be compressed to about half its original volume, and the bell itself will be about half filled with water. But if a supply of air be maintained at a pressure equal to the depth of water at which the bell is submerged, not only will the water be kept down to the cutting edge, but the bell will be ventilated and it will be possible for its occupants to work for hours at a stretch.

Tradition gives Roger Bacon, in 1250, the credit for being the originator of the diving bell, but actual records are lost in antiquity. Of the records preserved to us, probably one of the most trustworthy is an account given in Kaspar Schott’s work, Technica curiosa, published in the year 1664, which quoted from one John Taisnier, who was in the service of Charles V. This account describes an experiment which took place at Toledo, Spain, in the year 1538, before the emperor and some thousands of spectators, when two Greeks descended into the water in a large “kettle,” suspended by ropes, with its mouth downwards. The “kettle” was equipoised by lead fixed round its mouth. The men came up dry, and a lighted candle, which they had taken down with them, was still burning.

Francis Bacon, in the Novum Organum, lib. ii., makes the following reference to a machine, or reservoir, of air to which labourers upon wrecks might resort whenever they required to take breath:—

“A hollow vessel, made of metal, was let down equally to the surface of the water, and thus carried with it to the bottom of the sea the whole of the air which it contained. It stood upon three feet—like a tripod—which were in length something less than the height of a man, so that the diver, when he was no longer able to contain his breath, could put his head into the vessel, and having filled his lungs again, return to his work.”

But it was to Dr Edmund Halley, secretary of the Royal Society, that undoubtedly the honour is due of having invented the first really practical diving bell. This is described in the Philosophical Transactions, 1717, in a paper on “The Art of Living Under Water by means of furnishing air at the bottom of the sea in any ordinary depth.” Halley’s bell was constructed of wood, and was covered with lead, which gave it the necessary sinking weight, and was so distributed as to ensure that it kept a perpendicular position when in the water. It was in the form of a truncated cone, 3 ft. in diameter at the top, 5 ft. at the bottom and 8 ft. high. In the roof a lens was introduced for admitting light, and also a tap to let out the vitiated air. Fresh air was supplied to the bell by means of two lead-lined barrels, each having a bung-hole in the top and bottom. To the hole in the top was fixed a leathern tube, weighted in such a manner that it always fell below the level of the bottom of the barrel so that no air could escape. When, however, the tube was turned up by the attendant in the bell, the pressure of the water rising through the hole in the bottom of the barrel, forced the air through the tube at the top and into the diving bell. These barrels were raised and lowered alternately, with such success that Halley says that he, with four others, remained at the bottom of the sea, at a depth of 9 to 10 fathoms, for an hour and a half at a time without inconvenience of any sort.

|

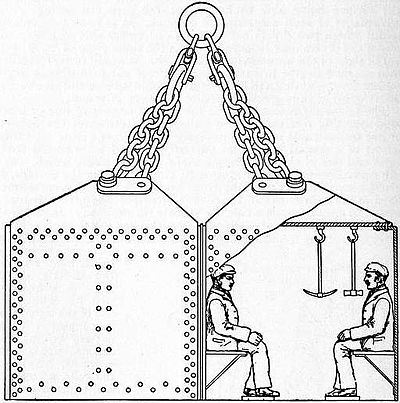

| Fig. 6.—Ordinary Diving Bell. |

This type of bell was used by John Smeaton in repairing the foundations of Hexham Bridge in 1778, but instead of weighted barrels, he introduced a force pump for supplying the necessary air. To Smeaton too we are indebted for the first diving bell plant in the form with which we are familiar to-day, that celebrated engineer having designed a square bell of iron, for use on the Ramsgate harbour works, in 1788. This bell, which measured 412 ft. in length, 3 ft. in width and 412 ft. in height, and weighed 212 tons, was made sufficiently heavy to sink by its own weight. It afforded room enough for two men to work, and was supplied with air by a force pump worked from a boat at the surface.

Though the diving bell has been largely superseded by the modern diving apparatus, it is still used on certain classes of work the magnitude of which justifies the expense entailed, for it is not only a question of the cost of the bell, but of the powerful steam-driven crane which is needed to lower and raise it, and also of the gantry on which the crane travels. Sometimes a barge or other vessel is used for working the bell.

At the present day, two types of diving bell are employed—the ordinary bell, and the air-lock bell, which, however, is not so largely used.

On the new national harbour works at Dover, four large diving bells of the ordinary type (fig. 6) were employed. These bells, in each of which from four to six men descended at a time, consisted of steel chambers, open at the bottom, measuring 17 ft. long by 1012 ft. wide by 7 ft. high, and each weighed 35 tons. The ballast, which at once gives the necessary sinking weight to the bell and maintains its equilibrium, consisted of slabs of cast iron bolted to the walls of the bell, inside. Each bell was fitted with loud-sounding telephonic apparatus, by means of which the occupants could communicate either with the men attending the crane or the men looking after the air compressors at the surface. Electric lamps, supplied with current by a dynamo in the compressor room, gave the necessary light inside the bell. Seats and foot rails were provided for the men, and there were racks and hooks for the various tools. Suspended from the roof was an iron skip into which the men threw the