of 10,000 ohms each. The deflection observed on the galvanometer

when the lines are leaky is d, while D is the deflection obtained

through one coil of the galvanometer with all the other resistances

in circuit; and assuming that no leakage exists on the lines, this

deflection is calculated from the “constant” of the instrument,

i.e., from the known deflection obtained with a definite current.

For the purpose of avoiding calculation, tables are provided showing

the values of the total insulation according to the formula,

corresponding to various values of d. If the insulation per mile,

i.e., the total insulation multiplied by the mileage of the wire loop,

is found to be less than 200,000 ohms, the wire is considered to be

faulty. The climatic conditions in the British Islands are such

that it is not possible to maintain, in unfavourable weather, a higher

standard than that named, which is the insulation obtained when

all the insulators are in perfect condition and only the normal

leakage, due to moisture, is present.

There are three kinds of primary batteries in general use in the British Postal Telegraph Department, viz., the Daniell, the bichromate, and the Leclanché. The Daniell type consists of a teak trough divided into five cells by slate partitions coated with marine glue. Each cell contains a zinc plate, immersed in a solution of zinc sulphate, and also a Batteries. porous chamber containing crystals of copper sulphate and a copper plate. The electromotive force of each cell is 1·07 volts and the resistance 3 ohms. The Fuller bichromate battery consists of an outer jar containing a solution of bichromate of potash and sulphuric acid, in which a plate of hard carbon is immersed; in the jar there is also a porous pot containing dilute sulphuric acid and a small quantity (2 oz.) of mercury, in which stands a stout zinc rod. The electromotive force of each cell is 2·14 volts, and the resistance 4 ohms. The Leclanché is of the ordinary type, and each cell has an electromotive force of 1·64 volts and a resistance of 3 to 5 ohms (according to the size of the complete cell, of which there are three sizes in use). Dry cells, i.e. cells containing no free liquid, but a chemical paste, are also largely employed; they have the advantage of great portability.

Primary batteries have, in the case of all large offices, been displaced by accumulators. The force of the set of accumulator cells provided is such as to give sufficient power for the longest circuit to be worked, the shorter circuits being brought up approximately to a level, as regards Accumulators. resistance, by the insertion of resistance coils in the circuit of the transmitting apparatus of each shorter line. A spare set of accumulators is provided for every group of instruments in case of the failure of the working set. For working “double current,” two sets of accumulators are provided, one set to send the positive and the other set the negative currents; that is to say, when, for example, a double current Morse key is pressed down it sends, say, a positive current from one set, but when it is allowed to rise to its normal position then a negative current is transmitted from the second set of accumulators. It is not possible to work double current from one set alone, as in this case, if one key of a group of instruments is up and another is down, the battery would be short-circuited and no current would flow to line. The size of the accumulators employed varies from a cell capable of an output of 8 ampere-hours, to a size giving 750 ampere-hours.

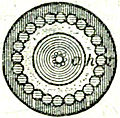

Submarine Cables.—A submarine cable (figs. 5-7), as usually manufactured, consists of a core a in the centre of which is a strand of copper wires varying in weight for different cables between 70 and 650 ℔ to the nautical mile. The stranded form was suggested by W. Thomson (Lord Kelvin) at a meeting of the Philosophical Society of Glasgow in 1854, because its greater flexibility renders it less likely to damage the insulating envelope during the manipulation of the cable. The central conductor is covered with several continuous coatings of gutta-percha, the total weight of which varies between 70 and 650 ℔ to the mile. Theoretically for a given outside diameter of core the greatest speed of signalling through a cable is obtained when the diameter of the conductor is ·606 (1/√ε) the diameter of the core, but this ratio makes the thickness of the gutta-percha covering insufficient for mechanical strength. Owing to the high price of gutta-percha the tendency, of recent years, has been to approximate more closely to the theoretical dimensions, and a thickness of insulating material which formerly would have been considered quite insufficient is now very generally adopted with complete success. Of two transatlantic cables laid in 1894, the core of one consisted of 500 ℔ copper and 320 ℔ gutta-percha per mile, and that of the other of 650 ℔ copper and 400 ℔ gutta-percha; whereas for the similarly situated cable laid in 1866 the figures were 300 ℔ copper and 400 ℔ gutta-percha. The core is served with a thick coating of wet jute, yarn or hemp (h), forming a soft bed for the sheath, and, to secure immunity from the ravages of submarine boring animals, e.g. Teredo navalis, it has been found necessary, for depths not exceeding 300 fathoms, to protect the core with a thin layer of brass tape. The deep sea portion is sheathed with galvanized iron or steel wires (in the latter case offering a breaking strain of over 80 tons per sq. in., with an elongation of at least 5 per cent.), the separate wires being first covered with a firm coating of tape and Chatterton’s compound (a mixture of gutta-percha, rosin and Stockholm tar). Sometimes the wires are covered with the compound alone, and the whole cable after being sheathed is finally covered with tarred tape. The weight of the iron sheath varies greatly according to the depth of the water, the nature of the sea bottom, the prevalence of currents, and so on. Fig. 5 shows the intermediate type again sheathed with a heavy armour to resist wear in the shallow water near shore. In many cases a still heavier type is used for the first mile or two from shore, and several intermediate types are often introduced, tapering gradually to the thin deep-water type.

Fig. 5. | |

Fig. 6. |

Fig. 7. |

| Figs. 5–7—Sections of three types of Submarine Cables, full size. Fig. 5.—Type of shore end. Fig. 6.—Intermediate type. Fig. 7.—Deep sea type. | |

The cost of the cable before laying depends on the dimensions of its core, the gutta-percha, which still forms the only trustworthy insulator known, constituting the principal item of the expense; for an Atlantic cable of the most approved construction the cost may be taken at £250 to £300 per nautical mile.

In manufacturing a cable (fig. 8) the copper strand is passed through a vessel A containing melted Chatterton’s compound, then through the cylinder C, in which a quantity of gutta-percha, purified by repeated washing in hot water, by mastication, and by filtering through wire-gauze filters, is Manufacture. kept warm by a steam-jacket. As the wire is pulled through, a coating of gutta-percha, the thickness of which is regulated by the die D, is pressed out of the cylinder by applying the requisite pressure