The sand rock must be blasted in mining; but in falling it readily breaks into fine sand, which only requires a little crushing and washing to prepare it for market. The output during 1888 varied between 1200 and 1500 tons per month, all of which is carried across the valley and the river to a siding on the railroad at Grantville Station, about 1½ miles distant, by means of a tramway, conveying iron buckets, with a capacity of about 125 pounds each of dried sand. This tramway is described in detail in Report F, pp. 79 and 80, as well as the plant used for washing and drying the sand.

The old tunnel at this quarry has been entirely abandoned, and the material from the new tunnel is conveyed to the washer by means of a short incline, passing thence into the original drying houses, as formerly. The entire operation is a very simple one and does not require any skilled labor. In May 1888 about 26 miners were employed at the quarry at a dollar a day.

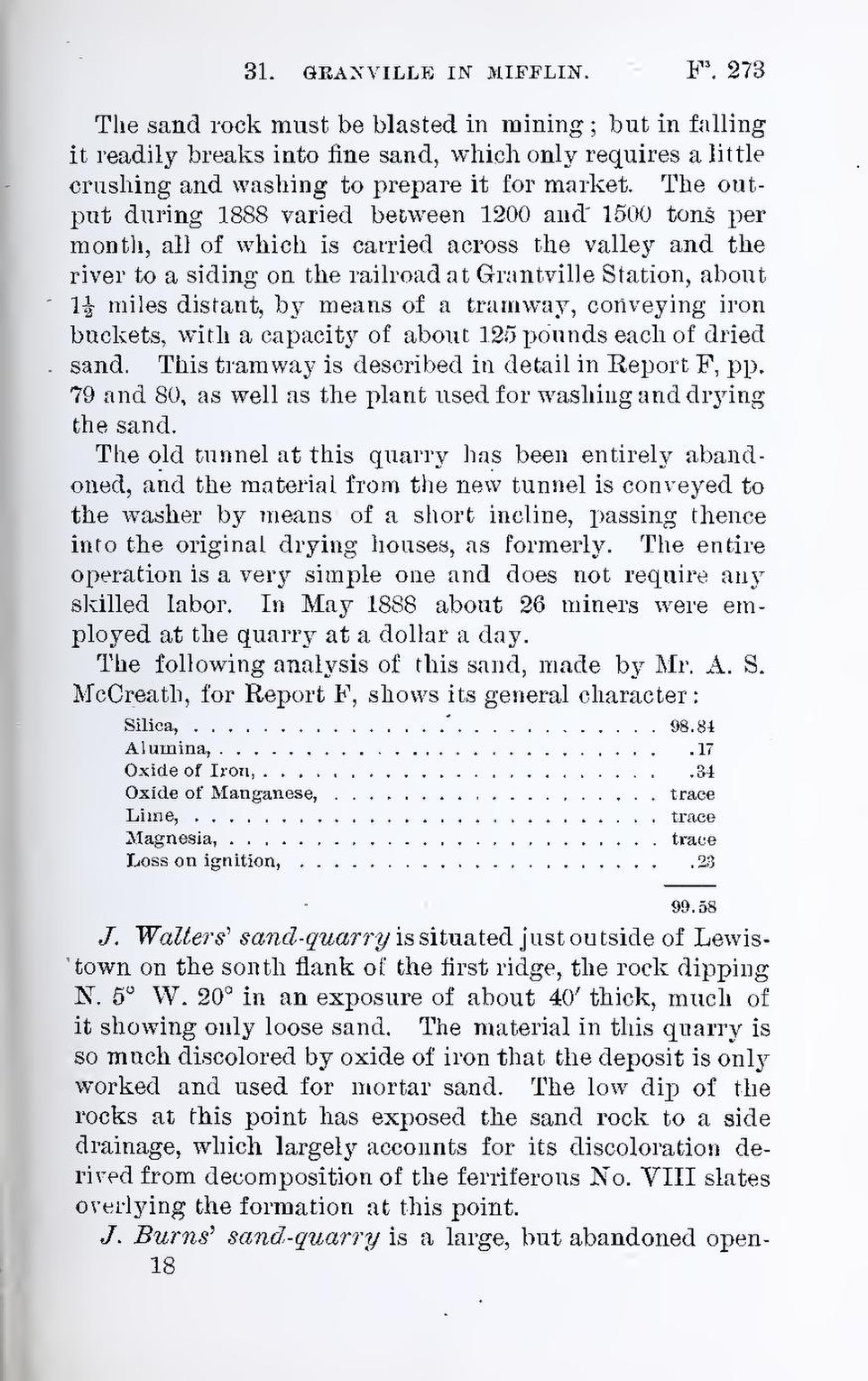

The following analysis of this sand, made by Mr. A. S. McCreath, for Report F, shows its general character:

| Silica, | 98.84 |

| Alumina, | .17 |

| Oxide of Iron, | .34 |

| Oxide of Manganese, | trace |

| Lime, | trace |

| Magnesia, | trace |

| Loss on ignition, | .23 |

| 99.58 |

J. Walters’ sand-quarry is situated just outside of Lewistown on the south flank of the first ridge, the rock dipping N. 5° W. 20° in an exposure of about 40′ thick, much of it showing only loose sand. The material in this quarry is so much discolored by oxide of iron that the deposit is only worked and used for mortar sand. The low dip of the rocks at this point has exposed the sand rock to a side drainage, which largely accounts for its discoloration derived from decomposition of the ferriferous No. VIII slates overlying the formation at this point.

J. Burns’ sand-quarry is a large, but abandoned open-