to force the air out, though for this purpose a fraction of a pound above the atmospheric should suffice; and frequently better results are obtained with such a slight excess than with a greater pressure. A subsequent chapter on radiators will discuss the action of air and position of an air valve.

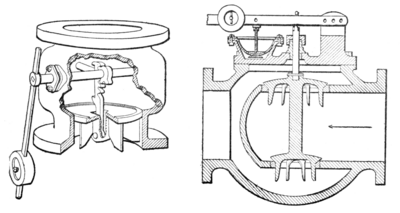

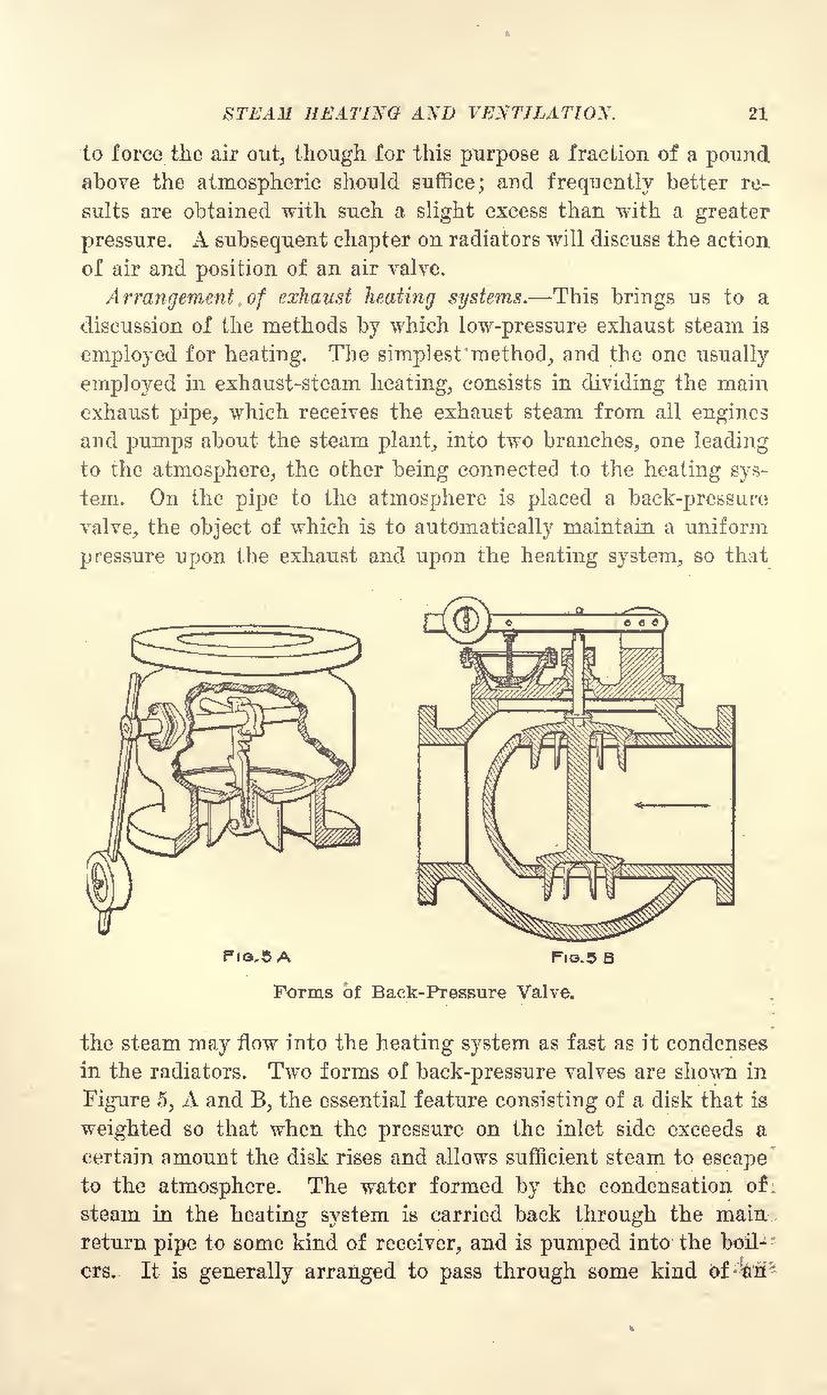

Arrangement of exhaust heating systems.—This brings us to a discussion of the methods by which low-pressure exhaust steam is employed for heating. The simplest method, and the one usually employed in exhaust-steam heating, consists in dividing the main exhaust pipe, which receives the exhaust steam from all engines and pumps about the steam plant, into two branches, one leading to the atmosphere, the other being connected to the heating system. On the pipe to the atmosphere is placed a back-pressure valve, the object of which is to automatically maintain a uniform pressure upon the exhaust and upon the heating system, so that the steam may flow into the heating system as fast as it condenses in the radiators. Two forms of back-pressure valves are shown in Figure 5, A and B, the essential feature consisting of a disk that is weighted so that when the pressure on the inlet side exceeds a certain amount the disk rises and allows sufficient steam to escape to the atmosphere. The water formed by the condensation of steam in the heating system is carried back through the main return pipe to some kind of receiver, and is pumped into the boilers. It is generally arranged to pass through some kind of an