Popular Mechanics/Volume 49/Issue 1/Build This Model of Flying Cloud

SHIP-MODEL PRIZES

Few hobbies enable the amateur to produce auch beautiful work with so few tools and such inexpensive material as ship-model building. To encourage such a worth-while and pleasant pastime, Popular Mechanics Magazine offers the following awards for the best models of the "Flying Cloud" made from plans published in this and subsequent issues:

- First, $100 cash and gold medal.

- Second, $50 cash and silver medal.

- Third, $25 cash and bronze medal.

- Five awards, $10 cash and bronze medal.

- Five awards. $5 cash and bronze medal.

Bronze medals also will be awarded for excellence in workmanship.

The contest is open to everyone, regardless of age or sex. The conditions are very simple, and full details will be aupplied to every reader addressing the Editor, Amateur Mechanics department, Popular Mechanics Magazine, 200 E. Ontario st., Chicago.

With the hull carved to shape, as in Fig. 19, the next step is the erection of the bulwarks. Cut a rabbet on each side of the quarterdeck, as shown in Fig. 18, and a similar one on each side of the after end of the foc's'le head. These rabbets should be about 11⁄4 in. long and a stout 1⁄16 in. deep; the bottom of the rabbets should be cut in line with the deck edge. Before going any further. it will be well to mark in the deck planking. Mark center lines down the decks, and, with the dividers, lay off the planks on either side of the lines, 1⁄8 in. wide. Rule pencil lines lightly along the decks, defining the planks. Cut a strip of wood 1 in. wide and 1⁄16 in. thick, make one edge straight and use this as a straightedge when ruling and scoring the lines: the flexible wood will lie closer to the deck than a regular straightedge. Now take a putty knife or similar tool, and score in the planking lines as shown in Fig. 25. A scriber will do for this job, but the point must be slightly rounded, else it has a tendency to follow the grain of the wood, and produce crooked "planks." The putty knife, used as shown, is an excellent tool for the job. After the deck lines have been scored in, stain the decks slightly with light-oak wood dye, made very light with turpentine. The object here is to get a deck that will look weatherworn yet "clean."

The deck should be very slightly brownish-yellow. Don't leave the decks white; ships' decks were

never so. After the stain has set, give the decks three coats of varnish, rubbing each coat down with the very finest steel wool: the last rubbing should leave the decks smooth, but not shiny.

Take a piece of wood, 3⁄32 in. thick and about 3 in. wide, and cut it to length, so that it will fit snugly between the after end of the foc's'le and the forward edge of the quarterdeck, just back of the rabbets. Hold the strip down on the deck, projecting over the edge of the hull, as in Fig. 21, and run a pencil around the hull as indicated, to mark the shape of the deck edge on the strip. Cut this edge to the pencil line, and then, with the dividers set to 1⁄4 in., run another mark along the strip inside the curved edge. Cut to this line, and you have a waterway strip. 1⁄4 in. wide, which is glued to the deck, as indicated in Fig. 20, the outer edge of the strip being even with the back of the rabbets at each end, and an even distance from the edge of the hull all along. A few pins will assist the glue in holding. Fit a similar strip on the other side.

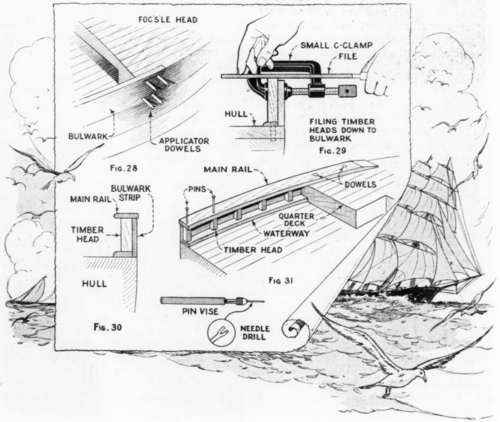

Make some 1⁄8-in. square strips of wood, and from them cut the timber heads, shown in Fig. 22, in the circle. The peg portion is 3⁄8 in. long, and the square part 1 in. long. Here we digress a little. Amidships the sides of our model are approximately vertical and the bulwarks correspond. From amidships aft, the upper part of the hull leans inward or "tumbles home" as the nautical term has it. and the bulwarks tumble home in the same degree. From amidships forward the upper part of the hull curves outward, or "flares," and the flare becomes more pronounced the further forward we go, and, as the timber heads represent the upper part of the ribs in a real ship, they consequently follow the tumbling or flaring lines of the hull. (See Fig. 23.) So, in drilling the holes for the timber heads through the waterways, the flare or tumble home must be taken into account, and the holes drilled to correspond. When marking off for drilling, make the holes come so that the outer edges of the timber heads will be exactly on the outer edges of the waterways. Only four timber heads with the pegs are needed on each side: the remainder may be dummies, glued on later. There are 23 timber heads on each side, hence the pegged ones must be spaced so that, when the others are glued on, the spaces between all will be equal. Make the pegged heads the second and fifth ones from the foc's'le; one about amidships and the second one from the quarterdeck. Drill the holes and glue the heads in place, on each side.

Now cut a strip of wood a stout 1⁄16 in. thick, long enough to reach from the outer end of the foe's'le rabbet to the outer end of the quarterdeck rabbet, and about 2 in. wide. Shape one edge very carefully until it fits the deck perfectly from rabbet to rabbet. This strip will form the bul- wark. Get a dozen or so of wooden "applicators" or iodine-swab sticks from the drug store, for use as dowels. Glue the after end of the bulwark into the rabbet at the quarterdeck, clamping it as shown in Fig. 24; run glue into the ledge formed by the waterway and deck; glue the outer sides of the timber heads, and then proceed forward with the strip, as in Fig. 27. fastening it in place by pinning to the waterway as in Figs. 24 and 25, and clamping it to the timber heads by means of spring clothespins, as in Fig. 26. The timber heads will help spring the thin strip to shape forward and aft. At the foc's'le head, drill small holes and dowel the strip to the hull, Fig. 28. When the glue has set, remove the clamp at the after end and insert some glued dowels. Pins may be used instead of the applicators, but the advantage of the latter is that one can carve right through them, and this is of special value here, since the bulwark should run smoothly along with the hull lines, and this usually necessitates some carving, filing and sandpapering at the ends. Now trim the top of the bulwark down until it makes a smooth curve from end to end with the sheer of the foc's'le and quarterdecks, and file the timber heads down, clamping them as in Fig. 20, while filing. Cut off and glue in place the remaining timber heads, clamping them to the bulwark with spring clothespins, spacing them equally and filing them down level with the top of the bulwark. Round off the inboard edges of the waterways, as in Fig. 30.

For work of this kind, get some packages of ordinary dressmakers' pins, and also a package or two of the very small pins known as "Lills." These are about 1⁄2 in. long, and are essential.

It is wise, at this time, to paint the inside of the bulwarks, since they are hard to get at later. Give them three or four coats of white japan color, thinned with turps, then a final coat of eggshell-gloss

white enamel. Don't use a full-gloss enamel anywhere on the model. The japan paint is known variously as "colors in japan," "carriage colors" and "japan colors" and they are simply what the names indicate: pigments ground in japan drier instead of in oil. They dry fast and flat. If they cannot be obtained locally, use artists' oil colors, mixed with turps and japan drier. In addition to the white, a steel-gray will be needed, also a pure green, cream, brown, vermilion and ivory black.

Cut a strip of white pine, 1⁄8 in. thick, 3⁄8 in. wide and 16 in. long, for the main rail. Starting 3 in. back on the quarterdeck, glue and dowel the strip down as in Fig. 31, allowing the outer edge to project 1⁄16 in. over the hull edge. Carry the strip forward, gluing and pinning it to the timber heads and the bulwark, and keeping the projection 1⁄16 in. over the latter; pin into every timber head. The strip may be a little hard to bend at the forward curve, but patience will do it. It should end, forward. 23⁄4 in. back of the foc's'le, just on the curve. Scarf or bevel the ends as shown in Fig. 31. Take a wide strip of wood, of the same thickness as the rail, lay it down so that it reaches from the forward end of the rail to a point beyond the bow, Fig. 37, and mark the curve of the bulwark and foc's'le deck on it. Trim to this line, mark 3⁄8 in. inside the trimmed edge and cut the inner curve. Glue, pin and dowel this to bulwark and foc's'le deck to form the continuation of the main rail. Cut the portion of the rail running around the quarterdeck in the same manner, then file and sand the joints. Fig. 45 shows part of the rail around the quarterdeck cut and ready for gluing.

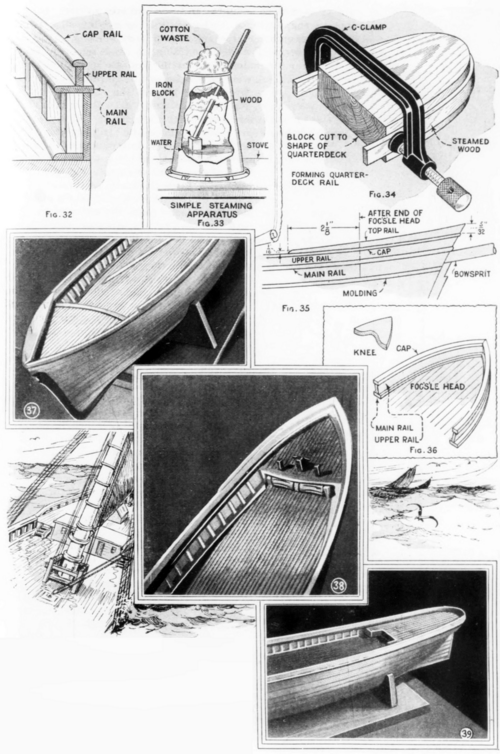

Above the main rail, as shown in Fig. 32, is an upper rail (sometimes called topgallant rail) and a cap or cap rail. The upper rail is formed from a piece 3⁄16 in. wide and 3⁄32 in. thick, glued and pinned to the main rail, 1⁄16 in. back from the outer edge of the latter. Make the midship portion the same length as the corresponding part of the main rail, and scarf the ends for joints like the main rail. The upper rail around the quarters and the stern is best bent to shape as shown in Figs. 33 and 34. The receptacle used for steaming the strip should be deep enough so that the center will be thoroughly pliable. and the wood should be steamed until this will be attained. It is then clamped around a piece of wood cut to the same shape as the quarterdeck, and left for twenty-four hours to dry. Since the upper rail on the foc's'le head should carry out the flare of the hull, it is best to cut it from a wider piece of wood, in the same manner as the main rail was fashioned, then carve it carefully on the outboard side to follow the flare of the hull lines, carving the inboard side afterward until the strip is of the proper thickness. The forward end of the first portion glued on should also be flared as it approaches the foc's'le, so that it will make a fair joint with the foc's'le rail. This may be accomplished by beveling the underside slightly, so as to make the top lean out. The flare at the bow is a little too extreme to make this easy to do with the foc's'le rail, hence the advice to cut this from a solid piece. A small knee, Fig. 36, is cut and fitted in the joint at the bow, down on the waterway, and the bow ends are glued and pinned to this.

When pinning small pieces like this, use the "Lills." and where there is danger of splitting the piece, screw a small C-clamp on the wood at the point where the pin is to be driven, and drive the pin down between the jaws of the clamp. The secret of driving these small pins straight is to use a very light hammer, and only the lightest blows: they will bend at once if struck hard. Where possible, a leading hole should be drilled for the pin, to help in keeping it straight. If small drills are hard to obtain, get a package of assorted needles, choose the size you want for the drill, and snip the eye off, leaving two little projecting prongs, as shown in Fig. 31. Take a three-cornered oil slip and sharpen the prongs in the same way as a flat drill is sharpened, slip the needle drill into a pin vise, and you will have the handiest drill possible for fine work. The modeler should have two sizes of the pin vises; one holding a drill around No. 65, the other the small needle drill. The larger drill will make leading holes for the larger pins.

When gluing the various pieces forming the bulwarks and rails together, be sure that both surfaces to be glued are well coated with the glue, but do not apply too much: then, when the pieces are pinned together and before the glue has set, run over the joints with a sharpened toothpick or similar tool and remove the surplus glue. Nothing looks worse than to see blobs and beads of glue in the joints, and it is only a matter of a second to remove the surplus while the glue is still soft. The cap rail is a stout 1⁄16 in. thick and 5⁄32 wide. The midship and foc's'le portions are easy to bend and apply "cold," using the points of small pins for fastenings, but the after part must be steamed and bent. Use the same block as before. Since it is difficult to bend a thin strip in the direction of its width without having it buckle, cut the piece to be bent 5⁄32 in. square, steam and bend it, then, after it is glued and pinned in place, file it down to the same thickness as the rest of the cap. Make scarf joints in the cap as in the other parts. Sandpaper the cap and the inboard edge of the main rail to the shape shown in Fig. 32.

One more rail must be added; the top rail on the foc's'le. This must be as thin as it can be made without splitting in applying, not over 5⁄64 in., and better 1⁄16 in. Remember that in this scale (1⁄8 in. to the foot) 1⁄16 in. represents 6 in., and a 6-in. timber is a pretty "hefty" one. This rail runs from the bow to a point on the cap 21⁄8 in. aft of the foc's'le: it is 5⁄32 in. high at the bow and 1⁄16 in. high at the after end. Notice, in Fig. 42, that the bow ends of the upper rail and this top rail slope forward, and make allowance for this in fitting. Some readers may find it easier to carve the top rails from the solid in the same way as the upper rail for the foc's'le, but, with care, they can be formed from thin strips, bent and twisted into place.

After sanding everything smooth, paint the inboard part of the main rail steel-gray all around. (See Fig. 38.) Paint the inside of the upper rail, the cap, the knee and the top rail white. The outside of the upper rail is painted black, and the cap is white all over, thus making a narrow white bead all around the outside of the ship. Do not paint the outside of the rail just yet. Notice the flare of bulwarks and rails, in Fig. 38.

The next step is to apply the molding. Fig. 44. This is a 1⁄16 by 1⁄8-in. strip, covering the deck and bulwark joint, and running parallel with the main rail from stem to stern. To insure that they are parallel, use a small block as a spacer between the two when pinning and gluing on the molding, as indicated in Fig. 44, sliding the block along as the molding is fastened. Steam the molding piece for running around the stern. After the glue has dried, cut off and drive in the pins, then take a small triangular or knife file and file grooves right down the center of both molding and main-rail projection, so as to bead them, then sand until the molding and rail look as in the detail, Fig. 44. This is a small point, but it makes a great difference in appearance of the moldings.

The channels are the timbers on the ship's side that carry the ends of the mast shrouds, and they are shown in Figs. 42 and 43. They are 1⁄8 in. thick and 5⁄32 in. wide. The fore and main channels are 37⁄8 in. long and the mizzen channels, 21⁄2 in. long. See also Fig. 46.

The foremast comes 27⁄8 in. aft of the end of the foc's'le, and the forward ends of the fore channels are 1⁄8 in. forward of the center line of the mast. The mainmast is 89⁄16 in., center to center, from the foremast, and the forward ends of the main channels are 1⁄8 in. forward of the center line of the mast. The mizzenmast is 65⁄8 in., center to center, aft of the main, and the mizzen channels are 1⁄8 in. forward of the center line, at their forward ends. Glue and pin these on strongly, using large pins, well driven in, at each end. Fig. 44 is one-fourth the size of the model.

(To Be Continued)

Latches Hold Cellar Doors Upright

Handy Latches for Cellar Doors

Many devices have been made for holding outside cellar doors open and in such a position that the opening will be guarded from both sides. However, in most cases these devices are of such a cumbersome nature that they make no appeal to the busy home owner. The trigger lock, shown in the illustration, is free from the usual objections, and can be easily installed by anyone. Upon the inside of each door, at the points shown, screweyes are placed. through which is passed a 1⁄2-in. rod with a lever attached to the outer end. Two holes are drilled into the siding of the house directly above the hinged side of each door, and the trigger locks are completed. When the doors are opened, the levers on the underside are pushed forward so that the sliding rods enter the holes in the siding and lock the doors in a vertical position. When released, the levers will not interfere with the closing of the doors.

Locking Ford Car Windows

The older Ford closed cars with the windows controlled by straps have no method of locking the windows. The doors can be locked by the use of locking handles but the window can be opened from the outside by prying the lower edge up from the iron strip on which it rests. A good lock for such windows can be made by drilling a 3⁄16-in. hole through the wood under the window frame, and into the space in which the windows are lowered. When leaving the car, large nails are inserted into the holes and the windows then cannot be dropped. The holes through the upholstery can be given a neat finish by using the parts of curtain fasteners that are clinched into the cloth of side curtains. The ball-headed screws are not used. These fasteners are attached to the cloth either by clinching them into it like an open-car side curtain, or by drilling two small holes, and using two fine wood screws.—E. T. Gunderson, Jr., Humboldt, Iowa.

Garment Hanger Keeps Moths Away

A good moth-proof garment hanger can easily be made from an ordinary wooden hanger by tacking a mothball receptacle on the underpart, as shown in the illustration. This will in no way interfere with the use of the hanger. A sheet of heavy cardboard is cut to a disk. the size of which depends on the size of the hanger. It is bent at the bottom, and a 1-in. hole is cut in one side to insert the mothballs. A number of small holes also are punched in the disk, so that the fumes of the balls will more easily penetrate the garment.

¶ Spots on varnished surfaces often can be removed by rubbing them well with a soft rag saturated in boiled linseed oil.

Barrel-Stave Sled

Barrel-Stave Sled Requiring Considerable Skill to Balance It

A barrel-stave sled that requires considerable skill to manage and provides great sport is made by attaching a seat well back of the center of the barrel stave as shown in the drawing. On such a sled there is naturally no method of controlling it other than by movements of the body or feet, but once the trick of managing it is mastered, it is controlled as easily as a bicycle when riding without steering.

Door Silencer for the Sick Room

Slamming doors are very annoying to sick persons. The trouble can readily be remedied in a simple manner by means of a heavy rubber band or a section, cut from an old inner tube, that is slipped over the door handles as shown in the drawing. This makes a good silencer and shock absorber, which will be highly appreciated by the patients.—Frank N. Coakley, Buffalo, N. Y.

Campers' Shaving Mirror

Handy Shaving Mirror for the Camp Which Can Be Attached to Tree or Post

Campers in the woods can make a serviceable holder for their shaving mirror that can be instantly clamped to a tree or post as shown in the illustration. Remove the adjusting rod from the back of a round rear-vision mirror used on an auto. The attachments differ somewhat for different makes of mirrors. Cut out a section of a small auto tire, about 3 in. wide, and drill or punch suitable holes through the middle of the tread, into which the mirror lugs can be inserted and pinned from the inside of the shoe. This completes the mirror clamp, which can then be pushed over a small tree at any desired height for shaving and other purposes.

Filing Cabinet Aids in Kitchen

I recently came into possession of a sheet-metal filing cabinet, which had been a piece of office furniture. This cabinet makes a dustless, mouse-proof and bugproof grocery and food container for my kitchen. The drawers close tightly and are of various sizes, the smaller ones being at the top. The shallow top drawers make excellent storage room for cookies and layer cakes, as they keep in the moisture. The next larger ones hold cereals, cornmeal and bread. The bottom one is for sugar. While I have to stoop to reach the lower drawer, the inconvenience is compensated for in that it can be shut with the foot. The tight construction of these compartments does away with waste, and they are absolutely clean. I painted the outside to match the color scheme of my kitchen. The filing cabinet is a space saver, too, as compared with the commercial types of kitchen cabinets. It stands 47 in. high, 18 in. deep and 15 in. wide.—Miss Hilda Ellyson Allen, Onawa, Iowa.

Eliminating Alcohol Odors

Length of Rubber Tubing, Attached to Overflow Pipe, Disposes of Alcohol Odors

The odor of alcohol, when used as an anti-freeze solution in the winter, is more or less objectionable, especially in a closed car or in a touring car when the curtains are used. The odor is caused by the escape of vapor from the overflow pipe of the radiator. To eliminate this odor from the car, get a length of rubber tubing large enough to fit the lower end of the radiator overflow pipe and fasten it to the latter. Let the tubing extend under the front side member of the frame and for about 6 in. above the bottom edge of the frame side member, where it should be fastened to the front-fender support bracket with tape or a small clamp, as shown in the drawing. In this way the vapors will all be carried away into the outer air and will not reach the inside of the car.—G. C. Douglas, Raleigh, N. C.

¶ A sash lock can be used as a bolt on a door, if the casing is flush with the surface of the door.