DYNAMO (a shortened form of “dynamo-electric machine,” from Gr. δύναμις, power), a machine for converting mechanical into electrical energy.

The dynamo ranks with the telegraph and telephone as one of the three striking applications of electrical and magnetic science to which the material progress that marked the second half of the 19th century was in no small measure due. Since the discovery of the principle of the dynamo by Faraday in 1831 the simple model which he first constructed has been gradually developed into the machines of 5000 horse-power or more which are now built to meet the needs of large cities for electric lighting and power, while at the same time the numbers of dynamos in use have increased almost beyond estimate. Yet such was the insight of Faraday into the fundamental nature of the dynamo that the theory of its action which he laid down has remained essentially unchanged. His experiments on the current which was

Fig. 1.set up in a coil of wire during its movement across the poles of a magnet led naturally to the explanation of induced electromotive force as caused by the linking or unlinking of magnetic lines of flux with an electric circuit. For the more definite case of the dynamo, however, we may, with Faraday, make the transition from line-linkage to the equivalent conception of “line-cutting” as the source of E.M.F.—in other words, to the idea of electric conductors “cutting” or intersecting[1] the lines of flux in virtue of relative motion of the magnetic field and electric circuit. On the 28th of October 1831 Faraday mounted a copper disk so that it could be rotated edgewise between the poles of a permanent horse-shoe magnet. When so rotated, it cut the lines of flux which passed transversely through its lower half, and by means of two rubbing contacts, one on its periphery and the other on its spindle, the circuit was closed through a galvanometer, which indicated the passage of a continuous current so long as the disk was rotated (fig. 1). Thus by the invention of the first dynamo Faraday proved his idea that the E.M.F. induced through the interaction of a magnetic field and an electric circuit was due to the passage of a portion of the electric circuit across the lines of flux, or vice versa, and so could be maintained if the cutting of the lines were made continuous.[2] In comparison with Faraday’s results, the subsequent advance is to be regarded as a progressive perfecting of the mechanical and electro-magnetic design, partly from the theoretical and partly from the practical side, rather than as modifying or adding to the idea which was originally present in his mind, and of which he already saw the possibilities.

A dynamo, then, is a machine in which, by means of continuous relative motion, an electrical conductor or system of conductors forming part of a circuit is caused to cut the lines of a magnetic field or fields; the cutting of the magnetic flux induces an electromotive force in the conductors, and when the circuit is closed a current flows, whereby mechanical energy is converted into electrical energy.

Little practical use could be made of electrical energy so long as its only known sources were frictional machines and voltaic batteries. The cost of the materials for producing electrical currents on a large scale by chemical action was prohibitive, while the frictional machine only yielded very small currents at extremely high potentials. In the dynamo, on the other hand, electrical energy in a convenient form could be cheaply and easily obtained by mechanical means, and with its invention the application of electricity to a wide range of commercial purposes became economically possible. As a converter of energy from one form to another it is only surpassed in efficiency by another electrical appliance, namely, the transformer (see Transformers). In this there is merely conversion of electrical energy at a high potential into electrical energy at a low potential, or vice versa, but in the dynamo the mechanical energy which must be applied to maintain the relative movement of magnetic field and conductor is absorbed, and reappears in an electrical form. A true transformation takes place, and the proportion which the rate of delivery of electrical energy bears to the power absorbed, or in other words the efficiency, is the more remarkable. The useful return or “output” at the terminals of a large machine may amount to as much as 95% of the mechanical energy which forms the “input.” Since it needs some prime mover to drive it, the dynamo has not made any direct addition to our sources of energy, and does not therefore rank with the primary battery or oil-engine, or even the steam-engine, all of which draw their energy more immediately from nature. Yet by the aid of the dynamo the power to be derived from waterfalls can be economically and conveniently converted into an electrical form and brought to the neighbouring factory or distant town, to be there reconverted by motors into mechanical power. Over any but very short distances energy is most easily transmitted when it is in an electrical form, and turbine-driven dynamos are very largely and successfully employed for such transmission. Thus by conducing to the utilization of water-power which may previously have had but little value owing to its disadvantageous situation, the dynamo may almost be said to have added another to our available natural resources.

The two essential parts of the dynamo, as required by its definition, may be illustrated by the original disk machine of Faraday. They are (1) the iron magnet, between the poles of which a magnetic field exists, and (2) the electrical conductors, represented by the rotating copper disk. The sector of the disk cutting the lines of the field forms part of a closed electric circuit, and has an E.M.F. induced in it, by reason of which it is no longer simply a conductor, but has become “active.” In its more highly developed form the simple copper disk is elaborated into a system of many active wires or bars which form the “winding,” and which are so interconnected as to add up their several E.M.F.’s. Since these active wires are usually mounted on an iron structure, which may be likened to the keeper or “armature” of a magnet rotating between its poles, the term “armature” has been extended to cover not only the iron core, but also the wires on it, and when there is no iron core it is even applied to the copper conductors themselves. In the dynamo of Faraday the “armature” was the rotating portion, and such is the case with modern continuous-current dynamos; in alternators, however, the magnet, or a portion of it, is more commonly rotated while the armature is stationary. It is in fact immaterial to the action whether the one or the other is moved, or both, so long as their relative motion causes the armature conductors to cut the magnetic flux.

Fig. 2.As to the ultimate reason why an E.M.F. should be thereby induced, physical science cannot as yet yield any surer knowledge than in the days of Faraday.[3] For the engineer, it suffices to know that the E.M.F. of the dynamo is due to the cutting of the magnetic flux by the active wires, and, further, is proportional to the rate at which the lines are cut.[4]

The equation of the electromotive force which is required in order to render this statement quantitative must contain three factors, namely, the density of the flux in the air-gap through which the armature conductors move, the active length of these wires, and the speed of their movement. For given values of the first and third factors and a single straight wire moved parallel to itself through a uniform field, the maximum rate of cutting is evidently obtained when the three directions of the lines of the conductor’s length and of the relative motion are respectively at right angles to each other, as shown by the three co-ordinate axes of fig. 2. The E.M.F. of the single wire is then

| E=BgLV × 10−8 volts | (1) |

where Bg is the density of the flux within the air-gap expressed in C.G.S. lines per square centimetre, L is the active length of the conductor within the field in centimetres, and V is the velocity of movement in centimetres per second. Further, the direction in which the E.M.F. has the above maximum value is along the length of the conductor, its “sense” being determined by the direction of the movement[5] in relation to the direction of the field.

The second fundamental equation of the dynamo brings to light its mechanical side, and rests on H. C. Oersted’s discovery of the interaction of a magnetic field and an electric current. If a straight electric conductor through which a current is passing be so placed in a magnetic field that its length is not parallel to the direction of the lines of flux, it is acted on by a force which will move it, if free, in a definite direction relatively to the magnet; or if the conductor is fixed and the magnet is free, the latter will itself move in the opposite direction. Now in the dynamo the active wires are placed so that their length is at right angles to the field; hence when they are rotated and an electric current begins to flow under the E.M.F. which they induce, a mutual force at once arises between the copper conductors and the magnet, and the direction of this force must by Lenz’s law be opposed to the direction of the movement. Thus as soon as the disk of fig. 1 is rotated and its circuit is closed, it experiences a mechanical pull or drag which must be overcome by the force applied to turn the disk. While the magnet must be firmly held so as to remain stationary, the armature must be of such mechanical construction that its wires can be forcibly driven through the magnetic field against the mutual pull. This law of electrodynamic action may be quantitatively stated in an equation of mechanical force, analogous to the equation (I.) of electromotive force, which states the law of electromagnetic induction. If a conductor of length L cm., carrying a current C amperes, is immersed in a field of uniform density Bg, and the length of the conductor is at right angles to the direction of the lines, it is acted on by a force

| F=BgLC × 10−1 dynes, | (2) |

and the direction of this force is at right angles to the conductor and to the field. The rate at which electrical energy is developed, when this force is overcome by moving the conductor as a dynamo through the field, is EC=BgLVC × 10−8 watts, whence the equality of the mechanical power absorbed and the electrical power developed (as required by the law of the conservation of energy) is easily established. The whole of this power is not, however, available at the terminals of the machine; if Ra be the resistance of the armature in ohms, the passage of the current Ca through the armature conductors causes a drop of pressure of CaRa volts, and a corresponding loss of energy in the armature at the rate of Ca2Ra watts. As the resistance of the external circuit Re is lowered, the current C=Ea / (Re + Ra) is increased. The increase of the current is, however, accompanied by a progressive increase in the loss of energy over the armature, and as this is expended in heating the armature conductors, their temperature may rise so much as to destroy the insulating materials with which they are covered. Hence the temperature which the machine may be permitted to attain in its working is of great importance in determining its output, the current which forms one factor therein being primarily limited by the heating which it produces in the armature winding. The lower the resistance of the armature, the less the rise of its temperature for a given current flowing through it; and the reason for the almost universal adoption of copper as the material for the armature conductors is now seen to lie in its high conductivity.[6]

Since the voltage of the dynamo is the second factor to which its output is proportional, the conditions which render the induced E.M.F. a maximum must evidently be reproduced as far as possible in practice, if the best use is to be made of a given mass of iron and copper. The first problem, therefore, in the construction of the dynamo is the disposition of the wires and field in such a manner that the three directions of field, length of active conductors, and movement are at right angles to one another, and so that the relative motion is continuous. Reciprocating motion, such as would be obtained by direct attachment of the conductors to the piston of a steam-engine, has been successfully employed only in the special case of an “oscillator,”[7] producing a small current very rapidly changing in direction. Rotary motion is therefore universally adopted, and with this two distinct cases arise. Either (A) the active length of the wire is parallel to the axis of rotation, or (B) it is at right angles to it.

|

| Fig. 3. |

|

| Fig. 4. |

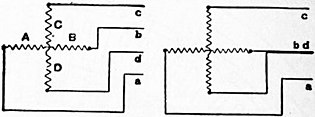

(A) If a conductor is rotated in the gap between the poles of a horse-shoe magnet, and these poles have plane parallel faces opposing one another as in fig. 3, not only is the density of the flux in the interpolar gap small, but the direction of movement is not always at right angles to the direction of the lines, which for the most part pass straight across from one opposing face to the other. When the conductor is midway between the poles (i.e. either at its highest or lowest point), it is at this instant sliding along the lines and does not cut them, so that its E.M.F. is zero. Taking this position as the starting-point, as the conductor moves round, its rate of line-cutting increases to a maximum when it has moved through a right angle and is opposite to the centre of a pole-face (as in fig. 3), from which point onward the rate decreases to zero when it has moved through 180°. Each time the conductor crosses a line drawn symmetrically through the gap between the poles and at right angles to the axis of rotation, the E.M.F. along its length is reversed in direction, since the motion relatively to the direction of the field is reversed. If the ends of the active conductor are electrically connected to two collecting rings fixed upon, but insulated from, the shaft, two stationary brushes bb can be pressed on the rings so as to make a sliding contact. An external circuit can then be connected to the brushes, which will form the “terminals” of the machine, the periodically reversed or alternating E.M.F. induced in the active conductor will cause an alternating current to flow through conductor and external circuit, and the simplest form of “alternator” is obtained. If the field cut by the straight conductor is of uniform density, and all the lines pass straight across from one pole-face to the other (both of which assumptions are approximately correct), a curve connecting the instantaneous values of the E.M.F. as ordinates with time or degrees of angular movement as abscissae (as shown at the foot of fig. 3), will, if the speed of rotation be uniform, be a sine curve. If, however, the conductor is mounted on an iron cylinder (fig. 4),[8] a sufficient margin being allowed for mechanical clearance between it and the poles, not only will the reluctance of the magnetic circuit be reduced and the total flux and its density in the air-gap Bg be thereby increased, but the path of the lines will become nearly radial, except at the “fringe” near the edges of the pole-tips; hence the relative directions of the movement and of the lines will be continuously at right angles. The shape of the E.M.F. curve will then be as shown in fig. 4—flat-topped, with rounded corners rapidly sloping down to the zero line.

|

| Fig. 5. |

|

| Fig. 6. |

But a single wire cannot thus be made to give more than a few volts, and while dynamos for voltages from 5 to 10 are required for certain purposes, the voltages in common use range from 100 to 10,000. It is therefore necessary to connect a number of such wires in series, so as to form an “armature winding.” If several similar conductors are arranged along the length of the iron core parallel to the first (fig. 5), the E.M.F.’s generated in the conductors which at any moment are under the same pole are similarly directed, and are opposite to the directions of the E.M.F.’s in the conductors under the other pole (cf fig. 5 where the dotted and crossed ends of the wires indicate E.M.F.’s directed respectively towards and away from the observer). Two distinct methods of winding thence arise, the similarity of the E.M.F.’s under the same pole being taken advantage of in the first, and the opposite E.M.F.’s under N and S poles in the second.

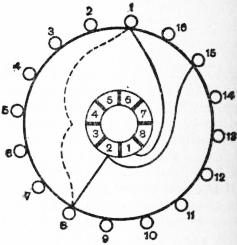

1. The first, or ring-winding, was invented by Dr Antonio Pacinotti of Florence[9] in 1860, and was subsequently and independently reintroduced in 1870[10] by the Belgian electrician, Zénobe Théophile Gramme, whence it is also frequently called the “Gramme” winding. By this method the farther end of conductor 1 (fig. 5) is joined in series to the near end of conductor 2; this latter lies next to it on the surface of the core or immediately above it, so that both are simultaneously under the same pole-piece. For this series connexion to be possible, the armature core must be a hollow cylinder, supported from the shaft on an open non-magnetic spider or hub, between the arms of which there is room for the internal wire completing the loop (fig. 6). The end of one complete loop or turn embracing one side of the armature core thus forms the starting-point for another loop, and the process can be continued if required to form a coil of two or more turns. In the ring armature the iron core serves the double purpose of conducting the lines across from one pole to the other, and also of shielding from the magnetic flux the hollow interior through which the connecting wires pass. Any lines which leak across the central space are cut by the internal wires, and the direction of cutting is such that the E.M.F. caused thereby opposes the E.M.F. due to the active conductors proper on the external surface. If, however, the section of iron in the core be correctly proportioned, the number of lines which cross the interior will bear but a small ratio to those which pass entirely through the iron, and the counter E.M.F. of the internal wires will become very small; they may then be regarded simply as connectors for joining the external active wires in series.

|

| Fig. 7. |

2. The second or drum method was used in the original “shuttle-wound” armatures invented by Dr Werner von Siemens in 1856, and is sometimes called the “Siemens” winding. The farther end of conductor 1 (fig. 5) is joined by a connecting wire to the farther end of another conductor 2′ situated nearly diametrically opposite on the other side of the core and under the opposite pole-piece. The near end of the complete loop or turn is then brought across the end of the core, and can be used as the starting-point for another loop beginning with conductor 2, which is situated by the side of the first conductor. The iron core may now be solid from the surface to the shaft, since no connecting wires are brought through the centre, and each loop embraces the entire armature core (fig. 7). By the formation of two loops in the ring armature and of the single loop in the drum armature, two active wires are placed in series; the curves of instantaneous E.M.F. are therefore similar in shape to that of the single wire (fig. 4), but with their ordinates raised throughout to double their former height, as shown at the foot of fig. 6.

Next, if the free ends of either the ring or drum loops, instead of being connected to two collecting rings, are attached to the two halves of a split-ring insulated from the shaft (as shown in fig. 7 in connexion with a drum armature), and the stationary brushes are so set relatively to the loops that they pass over from the one half of the split-ring to the other half at the moment when the loops are passing the centre of the interpolar gap, and so are giving little or no E.M.F., each brush will always remain either positive or negative. The current in the external circuit attached to the brushes will then have a constant direction, although the E.M.F. in the active wires still remains alternating; the curve of E.M.F. obtained at the brushes is thus (as in fig. 7) entirely above the zero line. The first dynamo of H. Pixii,[11] which immediately followed Faraday’s discovery, gave an alternating current, but in 1832[12] the alternator was converted into a machine giving a unidirected current by the substitution of a rudimentary “commutator” in place of mercury collecting cups.

(B) So far the length of the active wires has been parallel to the axis of rotation, but they may equally well be arranged perpendicularly thereto. The poles will then have plane faces and the active wires will be disposed with their length approximately radial to the axis of the shaft. In order to add their E.M.F.’s in series, two types of winding may be employed, which are precisely analogous in principle to the ring and drum windings under arrangement (A).

3. The discoidal or flat-ring armature is equivalent to a ring of which the radial depth greatly exceeds the length, with the poles presented to one side of the ring instead of embracing its cylindrical surface. A similar set of poles is also presented to the opposite side of the ring, like poles being opposite to one another, so that in effect each polar surface is divided into two halves, and the groups of lines from each side bifurcate and pass circumferentially through the armature core to issue into the adjacent poles of opposite sign.

4. In the disk machine, no iron core is necessary for the armature, the two opposite poles of unlike sign being brought close together, leaving but a short path for the lines in the air-gap through which the active wires are rotated.

|

| Fig. 8. |

If the above elementary dynamos are compared with fig. 1, it will be found that they all possess a distinctive feature which is not present in the original disk machine of Faraday. In the four types of machine above described each active wire in each revolution first cuts the group of lines forming a field in one direction, and then cuts the same lines again in the opposite direction relatively to the sense of the lines, so that along the length of the wire the E.M.F. alternates in direction. But in the dynamo of fig. 1 the sector of the copper disk which is at any moment moving through the magnetic field and which forms the single active element is always cutting the lines in the same manner, so that the E.M.F. generated along its radial length is continuous and unchanged in direction. This radical distinction differentiates the two classes of heteropolar and homopolar dynamos, Faraday’s disk machine of fig. 1 being the type of the latter class. In it the active element may be arranged either parallel or at right angles to the axis of rotation; but in both cases, in order to increase the E.M.F. by placing two or more elements in series, it becomes necessary either (1) to employ some form of sliding contact by which the current may be collected from the end of one active element and passed round a connecting wire into the next element without again cutting the field in the reverse direction, or (2) to form on the armature a loop of which each side is alternately active and inactive. The first method limits the possibilities of the homopolar machine so greatly when large currents and high voltages are required that it is now only used in rare instances, as e.g. occasionally in dynamos driven by steam-turbines which have a very high speed of rotation. The second alternative may be carried into effect with any of the four methods of armature winding, but is practically confined to the drum and disk types. In its drum form the field is divided into two or more projecting poles, all of the same sign, with intervening neutral spaces of equal width, and the span of the loop in the direction of rotation is at least equal to the width of a polar projection, as in fig. 8, where two polar projections are shown. Each side of the loop then plays a dual part; it first cuts the lines of one polar projection and generates an E.M.F., and next becomes an inactive connecting wire, while the action is taken up by the opposite side of the loop which has previously served as a connector but now cuts the lines of the next polar projection. The E.M.F. is thus always in the same direction along the side which is at any moment active, but alternates round the loop as a whole, and the distinctive peculiarity of the homopolar machine, so soon as any form of “winding” is introduced into its armature, is lost. It results that the homopolar principle, which would prima facie appear specially suitable for the generation of a unidirectional E.M.F. and continuous current, can seldom be used for this purpose and is practically confined to alternators. It may therefore be said that in almost all dynamos, whether they supply an alternating or a continuous current in the external circuit, the E.M.F. and current in the armature are alternating.

Ring winding was largely employed in early continuous-current dynamos and also in the alternators of Gramme and H. Wilde, and later of Auguste de Méritens. Disk winding was also successfully introduced for alternators, as in the magneto-machines of Nollet (1849) and the alternators of Wilde (1866) and Siemens (1878), and its use was continued in the machines of W. M. Mordey and S. Z. Ferranti. But although the ring, discoidal-ring and disk methods of winding deserve mention from their historical importance, experience has shown that drum winding possesses a marked superiority for both electrical and manufacturing reasons; the three former methods have in fact been practically discarded in its favour, so that the drum method will hereafter alone be considered.

The drum coil, composed of several loops wound side by side, may therefore be regarded as the constituent active element out of which the armature winding of the modern dynamo is developed. Its application to the multipolar machine is easily followed from fig. 9, which illustrates the heteropolar type of dynamo. The span of the loops, which is nearly 180° or across the diameter of the two-pole machine, is reduced approximately to 90° in the four-pole or to 60° in the six-pole machine and so on, the curvature of the coil becoming gradually less as the number of poles is increased. The passage of a coil through two magnetic fields of opposite direction yields a complete wave of E.M.F., such as is shown in fig. 6, and the time in seconds taken to pass through such a complete cycle is the “period” of the alternating E.M.F. The number of complete periods through which the E.M.F. of the coil passes per second is called the “periodicity” or “frequency” of the machine. In the bipolar machine this is equal to the number of revolutions per second, and in the multipolar machine it is equal to the number of pairs of fields through which the coil passes in one second; hence in general the periodicity is pN / 60, where N = the number of revolutions per minute and p = the number of pairs of poles, and this holds true of the E.M.F. and current round the coil, even though the E.M.F. and current furnished to the external circuit may be rendered unidirectional or continuous. The only difference on this point is that in the continuous-current machine the poles are usually fewer than in the alternator, and the periodicity is correspondingly lower. Thus in the former case the number of poles ranges from 2 to 12 and the usual frequencies from 5 to 20; but with alternators the frequencies in commercial use range from 25 to 120, and in large machines driven by slow-speed engines the number of poles may even be as high as 96.

| |

| I. Smooth. | II. Toothed. |

| Fig. 9. | |

|

| Fig. 10. |

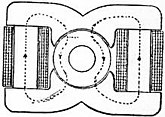

The drum coil may be applied either to the external surface of a rotating armature, the field-magnet being external and stationary (fig. 9), or to the internal surface of a stationary armature (fig. 10), the field-magnet being internal and rotating. While the former combination is universally adopted in the continuous-current dynamo, the latter is more usual in the modern alternator. In either case the iron armature core must be “laminated”; the passage of the lines of the field across its surface sets up E.M.F.’s which are in opposite directions under poles of opposite sign, so that if the core were a solid mass a current-sheet would flow along its surface opposite to a pole, and complete its circuit by passing through the deeper layers of metal or by returning in a sheet under a pole of opposite sign. Such “eddy-currents” can be practically avoided by dividing the metal core into laminations at right angles to the length of the active wires which are themselves arranged to secure the greatest rate of line-cutting and maximum E.M.F. The production of the eddy-current E.M.F. is not thereby prevented, but the paths of the eddy-currents are so broken up that the comparatively high resistance with which they meet reduces their amount very greatly. The laminae must be lightly insulated from one another, right up to their edges, so that the E.M.F.’s which still act across their thickness will not be added up along the length of the core, but will only produce extremely small currents circulating through the interior of the separate laminations. Each thin iron plate is either coated with an insulating varnish or has one of its sides covered with a sheet of very thin paper; the thickness of the laminae is usually about one-fortieth of an inch, and if this is not exceeded the rate at which energy is dissipated by eddy-currents in the core is so far reduced that it does not seriously impair the efficiency of the machine.

Lastly, the drum coils may be either attached to the surface of a smooth armature core (fig. 9, I.), or may be wound through holes formed close to the periphery of the core, or may be embedded in the slots between projecting iron teeth (figs. 9 [II.] and 10). Originally employed by Antonio Pacinotti in connexion with ring winding, the toothed armature was after some considerable use largely discarded in favour of the smooth core; it has, however, been reintroduced with a fuller understanding of the special precautions necessitated in its design, and it is now so commonly used that it may be said to have superseded the smooth-surface armature.

Not only does the toothed armature reduce the length of the air-gap to the minimum permitted by mechanical and magnetic considerations, and furnish better mechanical protection to the armature coils, but it also ensures the positive holding of the active wires against the mechanical drag which they experience as they pass through the magnetic field. Further, the active wires in the toothed armature are relieved of a large proportion of this mechanical drag, which is transferred to the iron teeth. The lines of the field, after passing through the air-gap proper, divide between the teeth and the slots in proportion to their relative permeances. Hence at any moment the active wires are situated in a weak field, and for a given armature current the force on them is only proportional to this weak field. This important result is connected with the fact that when the armature is giving current the distribution of the lines over the face of each tooth is distorted, so that they become denser on the “trailing” side than on the “leading” side;[13] the effect of the non-uniform distribution acting on all the teeth is to produce a magnetic drag on the armature core proportional to the current passing through the wires, so that the total resisting force remains the same as if the armature had a smooth core. The amount by which the stress on the active wires is reduced entirely depends upon the degree to which the teeth are saturated, but, since the relative permeability of iron even at a flux density of 20,000 lines per sq. cm. is to that of air approximately as 33 : 1, the embedded wires are very largely relieved of the driving stress. An additional gain is that solid bars of much greater width can be used in the toothed armature than on a smooth core without appreciable loss from eddy-currents within their mass.

A disadvantage of the slotted core is, however, that it usually necessitates the lamination of the pole-pieces. If the top of the slot is open, and its width of opening is considerably greater than the length of the air-gap from the iron of the pole-face to the surface of the teeth, the lines become unequally distributed not only at the surface of the teeth, but also at the face of the pole-pieces; and this massing of the lines into bands causes the density at the pole-face to be rhythmically varied as the teeth pass under it. No such variation can take place in a solid mass of metal without the production of eddy-currents within it; hence if the width of the slot-opening is equal to or exceeds twice the length of the single air-gap, lamination of the pole-pieces in the same plane as that of the armature core becomes advisable.

If the wires are threaded through holes or tunnels pierced close to the periphery of the core, the same advantages are gained as with open slots, and lamination of the pole-pieces is rendered unnecessary. But on the other hand, the process of winding becomes laborious and expensive, while the increase in the inductance of the coils owing to their being surrounded by a closed iron circuit is prejudicial to sparkless commutation in the continuous-current dynamo and to the regulation of the voltage of the alternator. A compromise is found in the half-closed slot, which is not uncommon in alternators, although the open slot is more usual in continuous-current dynamos.

|

| Fig. 11. |

With the addition of more turns to the elementary drum loop or of several complete coils, new questions arise, and in connexion therewith the two great classes of machines, viz. alternators and continuous-current dynamos, which have above been treated side by side, diverge considerably, so that they are best considered separately. The electromotive-force equation of the alternator will be first deduced, and subsequently that of the continuous-current machine.

Corresponding to the number of pairs of poles in the multipolar alternator, it is evident that there may also be an equal number of coils as shown diagrammatically in fig. 11. The additional coils, being similarly situated in respect to other pairs of poles, will exactly reproduce the E.M.F. of the original coil in phase and magnitude, so that when they are connected in series the total E.M.F. will be proportional to the number of coils in series; or if they are connected in parallel, while not adding to the E.M.F., they will proportionately increase the current-carrying capacity of the combination. But within each coil the addition of more loops will not cause an equal increase in the total E.M.F., unless the phases of the component E.M.F.’s due to the several turns are identical, and on this account it becomes necessary to consider the effect of the width of the coil-side.

|

| Fig. 12. |

If the additional loops are wound within the same slots as the original loop, the winding is “concentrated,” and each turn will then add the same E.M.F. But if the coil-side is divided between two or more slots, the phase of the E.M.F. yielded by the wires in one slot being different from that of the wires in another neighbouring slot, the sum of all the E.M.F.’s will be less than the E.M.F. of one component loop multiplied by the number of loops or turns in the coil. The percentage reduction in the E.M.F. will depend upon the number of the slots in a coil-side and their distance apart, i.e. on the virtual width of the coil-side expressed as a fraction of the “pole-pitch” or the distance measured along the pitch-line from the centre of one pole to the centre of a neighbouring pole of opposite sign (fig. 12). The winding is now to be regarded as “grouped,” since a small number of distinct phases corresponding to the groups within the two, three or four slots have to be compounded together. As the number of slots per coil-side is increased, an approach is gradually made to the case of “uniform distribution,” such as would obtain in a smooth-core armature in which the turns of the coil are wound closely side by side. Thus in the six-turn coil of fig. 12 A, which represents the development of a two-pole armature when the core is cut down to the shaft and opened out flat, there are in effect six phases compounded together, each of which differs but little from that of its next neighbour. With numerous wires lying still closer together a large number of phases are compounded until the distribution becomes practically uniform; the decrease in the E.M.F., as compared with that of a single turn multiplied by the number in series, is then immediately dependent upon the width of the coil-side relatively to the pole-pitch.

|

| Fig. 13. |

If the width of the inner loop of fig. 12 A is less than that of the pole-face, its two sides will for some portion of each period be moving under the same pole, and “differential action” results, the net E.M.F. being only that due to the difference between the E.M.F.’s of the two sides. The loop of smallest width must therefore exceed the width of pole-face, if direct differential action is to be avoided. The same consideration also determines the width of the outer loop; if this be deducted from twice the pole-pitch, the difference should not be less than the width of the pole-face, so that, e.g., in a bipolar machine the outer loop may stand to the S. pole exactly as the inner loop stands to the N. pole (fig. 13). In other words, the width of the coil-side must not exceed the width of the interpolar gap between two fields. Evidently then if the ratio of the pole-width to the pole-pitch approaches unity, the width of the coil-side must be very small, and vice versa. A compromise between these conflicting considerations is found if the pole is made not much more than half the pole-pitch, and the width of the coil-side is similarly about half the pole-pitch and therefore equal in width to the pole (fig. 13). A single large coil, such as that of fig. 12 A, can, however, equally well be divided into two halves by taking the end-connexions of one half of the turns round the opposite side of the shaft (fig. 12 B), as indeed has already been done in fig. 13. Each sheaf or band of active wires corresponding to a pole is thereby unaffected, but the advantages are gained that the axial length of the end-connexions is halved, and that they have less inductance. Thus if in fig. 11 there are four turns per coil, fig. 14 is electrically equivalent to it (save that the coils are here shown divided into two parallel paths, each carrying half the total current). When the large coils are divided as above described, it results that there are as many coils as there are poles, the outer loop of the small coil having a width equal to the pole-pitch, and the inner a width equal to the pole-face.

|

| Fig. 14. |

Such is the form which the “single-phase alternator” takes, but since only one-half of the armature core is now covered with winding, an entirely distinct but similar set of coils may be wound to form a second armature circuit between the coils of the first circuit. The phase of this second circuit will differ by 90° or a quarter of a period from that of the first, and it may either be used to feed an entirely separate external circuit possibly at a different pressure or, if it be composed of the same number of turns and therefore gives the same voltage, it may be interconnected with the first circuit to form a “quarter-phase alternator,” as will be more fully described later. By an extension of the same process, if the width of each side of a coil is reduced to one-sixth of the pole-pitch, three armature circuits can be wound on the same core, and a “three-phase alternator,” giving waves of E.M.F. differing in phase by 120°, is obtained.

The fundamental “electromotive-force equation” of the heteropolar alternator can now be given a more definite form. Let Za be the number of C. G. S. lines or the total flux, which issuing from any one pole flows through the armature core, to leave it by another pole of opposite sign. Since each active wire cuts these lines, first as they enter the armature core and then as they emerge from it to enter another pole, the total number of lines cut in one revolution by any one active wire is 2pZa. The time in seconds taken by one revolution is 60/N. The average E.M.F. induced in each active wire in one revolution being proportional to the number of lines cut divided by the time taken to cut them is therefore 2Za (pN / 60) × 10−8 volts. The active wires which are in series and form one distinct phase may be divided into as many bands as there are poles; let each such band contain t active wires, which as before explained may either form one side of a single large coil or the adjacent sides of two coils when the large coil is divided into two halves. Since the wires are joined up into loops, two bands are best considered together, which with either arrangement yield in effect a single coil of t turns. The average E.M.F.’s of all the wires in the two bands when added together will therefore be 4Za (pN / 60)t × 10−8. But unless each band is concentrated within a single slot, there must be some differential action as they cross the neutral line between the poles, so that the last expression is virtually the gross average E.M.F. of the loops on the assumption that the component E.M.F.’s always act in agreement round the coil and do not at times partially neutralize one another. The net average E.M.F. of the coil as a whole, or the arithmetical mean of all the instantaneous values of a half-wave of the actual E.M.F. curve, is therefore reduced to an extent depending upon the amount of differential action and so upon the width of the coil-side when this is not concentrated. Let k′=the coefficient by which the gross average E.M.F. must be multiplied to give the net average E.M.F.; then k′ may be called the “width-factor,” and will have some value less than unity when the wires of each band are spread over a number of slots. The net average E.M.F. of the two bands corresponding to a pair of poles is thus eav=4k′Za (pN / 60)t × 10−8.

The shape of the curve of instantaneous E.M.F. of the coil must further be taken into account. The “effective” value of an alternating E.M.F. is equal to the square root of the mean square of its instantaneous values, since this is the value of the equivalent unidirectional and unvarying E.M.F., which when applied to a given resistance develops energy at the same rate as the alternating E.M.F., when the effect of the latter is averaged over one or any whole number of periods. Let k″=the ratio of the square root of the mean square to the average E.M.F. of the coil, i.e.= Since it depends upon the shape of the E.M.F. curve, k″ is also known as the “form-factor”; thus if the length of gap between pole-face and armature core and the spacing of the wires were so graduated as to give a curve of E.M.F. varying after a sine law, the form-factor would have the particular value of π/2 √2=1·11, and to this condition practical alternators more or less conform. The effective E.M.F. of the two bands corresponding to a pair of poles is thus eeff=4k′k″Za (pN / 60)t × 10−8.

In any one phase there are p pairs of bands, and these may be divided into q parallel paths, where q is one or any whole number of which p is a multiple. The effective E.M.F. of a complete phase is therefore peeff/q. Lastly, if m=the number of phases into which the armature winding is divided, and τ=the total number of active wires on the armature counted all round its periphery, t=τ / 2pm, and the effective E.M.F. per phase is Ea=2k′k″Za (pNτ / 60mq) × 10−8.

The two factors k′ and k″ may be united into one coefficient, and the equation then takes its final form

| Ea=2KZa (pNτ / 60mq) × 10−8 volts | (1a) |

In the alternator q is most commonly 1, and there is only one circuit per phase; finally the value of K or the product of the width-factor and the form-factor usually falls between the limits of 1 and 1·25.

We have next to consider the effect of the addition of more armature loops in the case of dynamos which give a unidirectional E.M.F. in virtue of their split-ring collecting device, i.e. of the type shown in fig. 7 with drum armature or its equivalent ring form. As before, if the additional loops are wound in continuation of the first as one coil connected to a single split-ring, this coil must be more or less concentrated into a narrow band; since if the width becomes nearly equal to or exceeds the width of the interpolar gap, the two edges of the coil-side will just as in the alternator act differentially against one another during part of each revolution. The drum winding with a single coil thus gives an armature of the H- or “shuttle” form invented by Dr Werner von Siemens. Although the E.M.F. of such an arrangement may have a much higher maximum value than that of the curve of fig. 7 for a single loop, yet it still periodically varies during each revolution and so gives a pulsating current, which is for most practical uses unsuitable. But such pulsation might be largely reduced if, for example, a second coil were placed at right angles to the original coil and the two were connected in series; the crests of the wave of E.M.F. of the second coil will then coincide with the hollows of the first wave, and although the maximum of the resultant curve of E.M.F. may be no higher its fluctuations will be greatly decreased. A spacial displacement of the new coils along the pole-pitch, somewhat as in a polyphase machine, thus suggests itself, and the process may be carried still further by increasing the number of equally spaced coils, provided that they can be connected in series and yet can have their connexion with the external circuit reversed as they pass the neutral line between the poles.

|

| Fig. 15. |

|

| Fig. 16. |

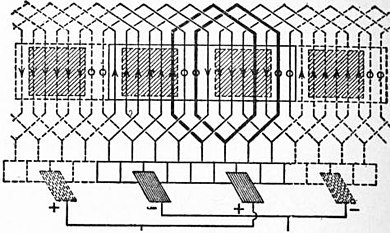

Given two coils at right angles and with their split-rings displaced through a corresponding angle of 90°, they may be connected in series by joining one brush to the opposite brush of the second coil, the external circuit being applied to the two remaining brushes.[14] The same arrangement may again be repeated with another pair of coils in parallel with the first, and we thus obtain fig. 15 with four split-rings, their connexions to the loops being marked by corresponding numerals; the four coils will give the same E.M.F. as the two, but they will be jointly capable of carrying twice the current, owing to their division into two parallel circuits. Now in place of the four split-rings may be employed the greatly simplified four-segment structure shown in fig. 16, which serves precisely the same purpose as the four split-rings but only requires two instead of eight brushes. The effect of joining brush 2 in fig. 15 across to brush 3, brush 4 to brush 5, 5 to 6, &c., has virtually been to connect the end of coil A with the beginning of coil B, and the end of coil B with the beginning of coil A′, and so on, until they form a continuous closed helix. Each sector of fig. 16 will therefore replace two halves of a pair of adjacent split-rings, if the end and beginning of a pair of adjacent coils are connected to it in a regular order of sequence. The four sectors are insulated from one another and from the shaft, and the whole structure is known as the “commutator,”[15] its function being not simply to collect the current but also to commute its direction in any coil as it passes the interpolar gap. The principle of the “closed-coil continuous-current armature” is thus reached, in which there are at least two parallel circuits from brush to brush, and from which a practically steady current can be obtained. Each coil is successively short-circuited, as a brush bridges over the insulation between the two sectors which terminate it; and the brushes must be so set that the period of short-circuit takes place when the coil is generating little or no E.M.F., i.e. when it is moving through the zone between the pole-tips. The effect of the four coils in reducing the percentage fluctuation of the E.M.F. is very marked, as shown at the foot of fig. 15 (where the upper curve is the resultant obtained by adding together the separate curves of coils A and B), and the levelling process may evidently be carried still further by the insertion of more coils and more corresponding sectors in the commutator, until the whole armature is covered with winding.

|

| Fig. 17. |

|

| Fig. 18. |

For example, figs. 17 and 18 show a ring and a drum armature, each with eight coils and eight commutator sectors; their resultant curve, on the assumption that a single active wire gives the flat-topped curve of fig. 4, will be the upper wavy line of E.M.F. obtained by adding together two of the resultant curves of fig. 15, with a relative displacement of 45°. The amount of fluctuation for a given number of commutator sectors depends upon the shape of the curve of E.M.F. yielded by the separate small sections of the armature winding; the greater the polar arc, the less the fluctuation. In practice, with a polar arc equal to about 0·75 of the pitch, any number of sectors over 32 per pair of poles yields an E.M.F. which is sensibly constant throughout one or any number of revolutions.

The fundamental electro-motive-force equation of the continuous-current heteropolar machine is easily obtained by analogy from that of the alternator. The gross average E.M.F. from the two sides of a drum loop without reference to its direction is as before 4Za (pN / 60) × 10−8 volts. But for two reasons its net average E.M.F. may be less; the span of the loop may be less than the pole-pitch, so that even when the brushes are so set that the position of short-circuit falls on the line where the field changes its direction, the two sides of the loop for some little time act against each other; or, secondly, even if the span of the loop be equal to the pole-pitch, the brushes may be so set that the reversal of the direction of its induced E.M.F. does not coincide with reversal of the current by the passage of the coil under the brushes. The net average E.M.F. of the loop is therefore proportional to the algebraic sum of the lines which it cuts in passing from one brush to another, and this is equal to the net amount of the flux which is included within the loop when situated in the position of short-circuit under a brush. The amount of this flux may be expressed as k′Za where k′ is some coefficient, less than unity if the span of the coil be less than the pole-pitch, and also varying with the position of the brushes. The net average E.M.F. of the loop is therefore

4k′Za (pN / 60) × 10−8.

In practice the number of sections of the armature winding is so large and their distribution round the armature periphery is so uniform, that the sum total of the instantaneous E.M.F.’s of the several sections which are in series becomes at any moment equal to the net average E.M.F. of one loop multiplied by the number which are in series. If the winding is divided into q parallel circuits, the number of loops in series is τ/2q, so that the total E.M.F. is Ea=2(k′ / q) Za (pN / 60)τ × 10−8 volts. Thus as compared with the alternator not only is there no division of the winding into separate phases, but the form-factor k′ disappears, since the effective and average E.M.F.’s are the same. Further whereas in the alternator q may=1, in the continuous-current closed-coil armature there can never be less than two circuits in parallel from brush to brush, and if more, their number must always be a multiple of two, so that q can never be less than two and must always be an even number. Lastly, the factor k′ is usually so closely equal to 1, that the simplified equation may in practice be adopted, viz.

| Ea=(2/q) (ZpN / 60) τ × 10−8 volts. | (1b) |

The fundamental equation of the electromotive force of the dynamo in its fully developed forms (1 a) (and 1 b) may be compared with its previous simple statement (I.). The three variable terms still find their equivalents, but are differently expressed, the density Bg being replaced by the total flux of one field Za, the length L of the single active wire by the total number of such wires τ, and the velocity of movement V by the number of revolutions per second. Even when the speed is fixed, an endless number of changes may be rung by altering the relative values of the remaining two factors; and in successful practice these may be varied between fairly wide limits without detriment to the working or economy of the machine. While it may be said that the equation of the E.M.F. was implicitly known from Faraday’s time onwards, the difficulty under which designers laboured in early days was the problem of choosing the correct relation of Za or τ for the required output; this, again, was due chiefly to the difficulty of predetermining the total flux before the machine was constructed. The general error lay in employing too weak a field and too many turns on the armature, and credit must here be given to the American inventors, E. Weston and T. A. Edison, for their early appreciation of the superiority in practical working of the drum armature, with comparatively few active wires rotating in a strong field.

Continuous-current Dynamos.—On passing to the separate consideration of alternators and continuous-current dynamos, the chief constructive features of the latter will first be taken in greater detail. As already stated in the continuous-current dynamo the armature is usually the rotating portion, and the The armature core.necessity of laminating its core has been generally described. The thin iron stampings employed to build up the core take the form of circular washers or “disks,” which in small machines are strung directly on the shaft; in larger multipolar machines, in which the required radial depth of iron is small relatively to the diameter, a central cast iron hub supports the disks. Since the driving force is transmitted through the shaft to the disks, they must in the former case be securely fixed by keys sunk into the shaft; when a central hub is employed (fig. 19) it is keyed to the shaft, and its projecting arms engage in notches stamped on the inner circumference of the disks, or the latter have dovetailed projections fitting into the arms. The disks are then tightly compressed and clamped between stout end-plates so as to form a nearly solid iron cylinder of axial length slightly exceeding the corresponding dimension of the poles. If the armature is more than 4 ft. in diameter, the disks become too large to be conveniently handled in one piece, and are therefore made in segments, which are built up so as to break joint alternately. Prior to assemblage, the external circumference of each disk is notched in a stamping machine with the required number of slots to receive the armature coils, and the longitudinal grooves thereby formed in the finished core only require to have their sharp edges smoothed off so that there may be no risk of injury to the insulation of the coils.

|

| Fig. 19. |

With open slots either the armature coils may be encased with wrappings of oiled linen, varnished paper and thin flexible micanite sheeting in order to insulate them electrically from the iron slots in which they are afterwards embedded; or the slots may be themselves lined with moulded troughs of micanite, &c., Armature winding.for the reception of the armature coils, the latter method being necessary with half-closed slots. According to the nature of the coils armatures may be divided into the two classes of coil-wound and bar-wound. In the former class, round copper wire, double-cotton covered, is employed, and the coils are either wound by hand directly on to the armature core, or are shaped on formers prior to being inserted in the armature slots. Hand-winding is now only employed in very small bipolar machines, the process being expensive and accompanied by the disadvantage that if one section requires to be repaired, the whole armature usually has to be dismantled and re-wound. Former-wound coils are, on the other hand, economical in labour, perfectly symmetrical and interchangeable, and can be thoroughly insulated before they are placed in the slots. The shapers employed in the forming process are very various, but are usually arranged to give to the finished coil a lozenge shape, the two straight active sides which fit into the straight slots being joined by V-shaped ends; at each apex of the coil the wire is given a twist, so that the two sides fall into different levels, an upper and a lower, corresponding to the two layers which the coil-sides form on the finished armature. Rectangular wire of comparatively small section may be similarly treated, and if only one loop is required per section, wide and thin strip can be bent into a complete loop, so that the only soldered joints are those at the commutator end where the loops are interconnected. But finally with massive rectangular conductors, the transition must be made to bar-winding, in which each bar is a half-loop, insulated by being taped after it has been bent to the required shape; the separate bars are arranged on the armature in two layers, and their ends are soldered together subsequently to form loops. As a general rule, whether bars or former-wound coils are employed, the armature is barrel-wound, i.e. the end-connexions project outwards from the slots with but little change of level, so that they form a cylindrical mass supported on projections from the end-plates of the core (fig. 19); but, in certain cases, the end-connexions are bent downwards at right angles to the shaft, and they may then consist of separate strips of copper bent to a so-called butterfly or evolute shape.

After the coils or loops have been assembled in the slots on the armature core, and the commutator has been fixed in place on the shaft, the soldering of the ends of the coils proceeds, by which at once the union of the end of one coil with the beginning of the next, and also their connexion to the commutator sectors, is effected, and in this lies the essential part of armature winding.

|

| Lap-loops Fig. 20. |

The development of the modern drum armature, with its numerous coils connected in orderly sequence into a symmetrical winding, as contrasted with the earlier Siemens armatures, was initiated by F. von Hefner Alteneck (1871), and the laws governing the interconnexion of the coils have now been elaborated into a definite system of Lap-winding.winding formulae. Whatever the number of wires or bars in each side of a coil, i.e. whether it consist of a single loop or of many turns, the final connexions of its free ends are not thereby affected, and it may be mentally replaced by a single loop with two active inducing sides. The coil-sides in their final position are thus to be regarded as separate primary elements, even in number, and distributed uniformly round the armature periphery or divided into small, equally spaced groups by being located within the slots of a toothed armature. Attention must then be directed simply to the span of the back connexion between the elements at the end of the armature further from the commutator, and to the span of the front connexion by which the last turn of a coil is finally connected to the first turn of the next in sequence, precisely as if each coil of many turns were reduced to a single loop. In order to avoid direct differential action, the span of the back connexion which fixes the width of the coil must exceed the width of the pole-face, and should not be far different from the pole-pitch; it is usually a little less than the pole-pitch. Taking any one element as No. 1 in fig. 20, where for simplicity a smooth-core bipolar armature is shown, the number of winding-spaces, each to be occupied by an element, which must be counted off in order to find the position of the next element in series, is called the “pitch” of the end-connexion, front or back, as the case may be. Thus the back pitch of the winding as marked by the dotted line in fig. 20 is 7, the second side of the first loop being the element numbered 1 + 7=8. In forming the front end-connexion which completes the loop and joins it to the next in succession, two possible cases present themselves. By the first, or “lap-winding,” the front end-connexion is brought backwards, and passing on its way to a junction with a commutator sector is led to a third element lying within the two sides of the first loop, i.e. the second loop starts with the element, No. 3, lying next but one to the starting-point of the first loop. The winding therefore returns backwards on itself to form each front end, but as a whole it works continually forwards round the armature, until it finally “re-enters,” after every element has been traversed. The development of the completed winding on a flat surface shows that it takes the form of a number of partially overlapping loops, whence its name originates. The firm-line portion of fig. 21 gives the development of an armature similar to that of fig. 18 when cut through at the point marked X and opened out; two of the overlapping loops are marked thereon in heavy lines. The multipolar lap-wound armature is obtained by simply repeating the bipolar winding p times, as indicated by the dotted additions of fig. 21 which convert it from a two-pole to a four-pole machine. The characteristic feature of the lap-wound armature is that there are as many parallel paths from brush to brush, and as many points at which the current must be collected, as there are poles. As the bipolar closed-coil continuous-current armature has been shown to consist in reality of two circuits in parallel, each giving the same E.M.F. and carrying half the total current, so the multipolar lap-wound drum consists of p pairs of parallel paths, each giving the same E.M.F. and carrying 1/2p of the total current. Thus in equation 1.b we have q=2p, and the special form which the E.M.F. equation of the lap-wound armature takes is Ea=Za (N / 60)τ × 10–8 volts. All the brushes which are of the same sign must be connected together in order to collect the total armature current. The several brush-sets of the multipolar lap-wound machine may again be reduced to two by “cross-connexion” of sectors situated 360°/p apart, but this is seldom done, since the commutator must then be lengthened p times in order to obtain the necessary brush contact-surface for the collection of the entire current.

Fig. 21. |

Wave-loops Fig. 22. |

Fig. 23. |

But for many purposes, especially where the voltage is high and the current small, it is advantageous to add together the inductive effect of the several poles of the multipolar machine by throwing the E.M.F.’s of half the total number of elements Wave-winding. into series, the number of parallel circuits being conversely again reduced to two. This is effected by the second method of winding the closed-coil continuous current drum, which is known as “wave-winding.” The front pitch is now in the same direction round the armature as the back pitch (fig. 22), so that the beginning of the second loop, i.e. element No. 15, lies outside the first loop. After p loops have been formed and as many elements have been traversed as there are poles, the distance covered either falls short of or exceeds a complete tour of the armature by two winding-spaces, or the width of two elements. A second and third tour are then made, and so on, until finally the winding again closes upon itself. When the completed winding is developed as in fig. 23, it is seen to work continuously forwards round the armature in zigzag waves, one of which is marked in heavy lines, and the number of complete tours is equal to the average of the back and front pitches. Since the number of parallel circuits from brush to brush is q=2, the E.M.F. equation of the wave-wound drum is Ea=pZa (N / 60)τ × 10−8 volts. Only two sets of brushes are necessary, but in order to shorten the length of the commutator, other sets may also be added at the point of highest and lowest potential up to as many in number as there are poles. Thus the advantage of the wave-wound armature is that for a given voltage and number of poles the number of active wires is only 1/p of that in the lap-wound drum, each being of larger cross-section in order to carry p times as much current; hence the ratio of the room occupied by the insulation to the copper area is less, and the available space is better utilized. A further advantage is that the two circuits from brush to brush consist of elements influenced by all the poles, so that if for any reason, such as eccentricity of the armature within the bore of the pole-pieces, or want of uniformity in the magnetic qualities of the poles, the flux of each field is not equal to that of every other, the equality of the voltage produced by the two halves of the winding is not affected thereby.

In appearance the two classes of armatures, lap and wave, may be distinguished in the barrel type of winding by the slope of the upper layer of back end-connexions, and that of the front connexions at the commutator end being parallel to one another in the latter, and oppositely directed in the former.

|

| Fig. 24. |

After completion of the winding, the end-connexions are firmly bound down by bands of steel or phosphor bronze binding wire, so as to resist the stress of centrifugal force. In the case of smooth-surface armatures, such bands are also placed at intervals along the length of the armature core, but in toothed armatures, although the coils are often in small machines secured in the slots by similar bands of a non-magnetic high-resistance wire, the use of hard-wood wedges driven into notches at the sides of the slots becomes preferable, and in very large machines indispensable. The external appearance of a typical armature with lap-winding is shown in fig. 24.

A sound mechanical construction of the commutator is of vital importance to the good working of the continuous-current dynamo. The narrow, wedge-shaped sectors of hard-drawn copper, with their insulating strips of thin mica, are built up into a cylinder, tightly clamped together, and turned in the lathe; The commutator.at each end a V-shaped groove is turned, and into these are fitted rings of micanite of corresponding section (fig. 19); the whole is then slipped over a cast iron sleeve, and at either end strong rings are forced into the V-shaped grooves under great pressure and fixed by a number of closely-pitched tightening bolts. In dynamos driven by steam-turbines in which the peripheral speed of the commutator is very high, rings of steel are frequently shrunk on the surface of the commutator at either end and at its centre. But in every case the copper must be entirely insulated from the supporting body of metal by the interposition of mica or micanite and the prevention of any movement of the sectors under frequent and long-continued heating and cooling calls for the greatest care in both the design and the manufacture.

On passing to the second fundamental part of the dynamo, namely, the field-magnet, its functions may be briefly recalled as follows:—It has to supply the magnetic flux; to provide for it an iron path as nearly closed as possible upon the armature, save for the air-gaps which must exist between the pole-system Forms of field-magnet.and the armature core, the one stationary and the other rotating; and, lastly, it has to give the lines such direction and intensity within the air-gaps that they may be cut by the armature wires to the best advantage. Roughly corresponding to the three functions above summarized are the three portions which are more or less differentiated in the complete structure. These are: (1) the magnet “cores” or “limbs,” carrying the exciting coils whereby the inert iron is converted into an electro-magnet; (2) the yoke, which joins the limbs together and conducts the flux between them; and (3) the pole-pieces, which face the armature and transmit the lines from the limbs through the air-gap to the armature core, or vice versa.

|

| Fig. 25. |

Of the countless shapes which the field-magnet may take, it may be said, without much exaggeration, that almost all have been tried; yet those which have proved economical and successful, and hence have met with general adoption, may be classed under a comparatively small number of types. For bipolar machines the single horse-shoe (fig. 25), which is the lineal successor of the permanent magnet employed in the first magneto-electric machines, was formerly very largely used. It takes two principal forms, according as the pole-pieces and armature are above or beneath the magnet limbs and yoke. The “over-type” form is best suited to small belt-driven dynamos, while the “under-type” is admirably adapted to be directly driven by the steam-engine, the armature shaft being immediately coupled to the crank-shaft of the engine. In the latter case the magnet must be mounted on non-magnetic supports of gun-metal or zinc, so as to hold it at some distance away from the iron bedplate which carries both engine and dynamo; otherwise a large proportion of the flux which passes through the magnet limbs would leak through the bedplate across from pole to pole without passing through the armature core, and so would not be cut by the armature wires.

|

| Fig. 26. |

Next may be placed the “Manchester” field (fig. 26)—the type of a divided magnetic circuit in which the flux forming one field or pole is divided between two magnets. An exciting coil is placed on each half of the double horse-shoe magnet, the pair being so wound that consequent poles are formed above and below the armature. Each magnet thus carries one-half of the total flux, the lines of the two halves uniting to form a common field where they issue forth into or leave the air-gaps. The pole-pieces may be lighter than in the single horse-shoe type, and the field is much more symmetrical, whence it is well suited to ring armatures of large diameter. Yet these advantages are greatly discounted by the excessive magnetic leakage, and by the increased weight of copper in the exciting coils. Even if the greater percentage which the leakage lines bear to the useful flux is neglected, and the cross sectional area of each magnet core is but half that of the equivalent single horse-shoe, the weight of wire in the double magnet for the same rise of temperature in the coils must be some 40% more than in the single horse-shoe, and the rate at which energy is expended in heating the coils will exceed that of the single horse-shoe in the same proportion.

Thirdly comes the two-pole ironclad type, so called from the exciting coil being more or less encased by the iron yoke; this latter is divided into two halves, which pass on either side of the armature. Unless the yoke be kept well away from the polar edges and armature, the leakage across the air into the yoke becomes considerable, especially if only one exciting coil is used, as in fig. 27 A; it is better, therefore, to divide the excitation between two coils, as in fig. 27 B, when the field also becomes symmetrical.

From this form is easily derived the multipolar type of fig. 28 or fig. 29, which is by far the most usual for any number of poles from four upwards; its leakage coefficient is but small, and it is economical in weight both of iron and copper.

|

| Fig. 27. |

As regards the materials of which magnets are made, generally speaking there is little difference in the permeability of “wrought iron” or “mild steel forgings” and good “cast steel”; typical (B, H) curves connecting the magnetizing force required with different flux-densities for these materials are given under Electromagnetism. On the other hand there is a Materials of magnets.marked inferiority in the case of “cast iron,” which for a flux-density of B=8000 C.G.S. lines per sq. cm. requires practically the same number of ampere-turns per centimetre length as steel requires for B=16,000. Whatever the material, if the flux-density be pressed to a high value the ampere-turns are very largely increased owing to its approaching saturation, and this implies either a large amount of copper in the field coils or an undue expenditure of electrical energy in their excitation. Hence there is a limit imposed by practical considerations to the density at which the magnet should be worked, and this limit may be placed at about B=16,000 for wrought iron or steel, and at half this value for cast iron. For a given flux, therefore, the cast iron magnet must have twice the sectional area and be twice as heavy, although this disadvantage is partly compensated by its greater cheapness. If, however, cast iron be used for the portion of the magnetic circuit which is covered with the exciting coils, the further disadvantage must be added that the weight of copper on the field-magnet is much increased, so that it is usual to employ forgings or cast steel for the magnet cores on which the coils are wound. If weight is not a disadvantage, a cast iron yoke may be combined with the wrought iron or cast steel magnet cores. An absence of joints in the magnetic circuit is only desirable from the point of view of economy of expense in machining the component parts during manufacture; when the surfaces which abut against each other are drawn firmly together by screws, the want of homogeneity at the joint, which virtually amounts to the presence of a very thin film of air, produces little or no effect on the total reluctance by comparison with the very much longer air-gaps surrounding the armature. In order to reduce the eddy-currents in the pole-pieces, due to the use of toothed armatures with relatively wide slots, the poles themselves must be laminated, or must have fixed to them laminated pole-shoes, built up of thin strips of mild steel riveted together (as shown in fig. 29).

|

| Fig. 28. |

However it be built up, the mechanical strength of the magnet system must be carefully considered. Any two surfaces between which there exists a field of density Bg experience a force tending to draw them together proportional to the square of the density, and having a value of Bg2 / (1·735 × 106) ℔ per sq. in. of surface, over which the density may be regarded as having the uniform value Bg. Hence, quite apart from the torque with which the stationary part of the dynamo tends to turn with the rotating part as soon as current is taken out of the armature, there exists a force tending to make the pole-pieces close on the armature as soon as the field is excited. Since both armature and magnet must be capable of resisting this force, they require to be rigidly held; although the one or the other must be capable of rotation, there should otherwise be no possibility of one part of the magnetic circuit shifting relatively to any other part. An important conclusion may be drawn from this circumstance. If the armature be placed exactly concentric within the bore of the poles, and the two or more magnetic fields be symmetrical about a line joining their centres, there is no tendency for the armature core to be drawn in one direction more than in another; but if there is any difference between the densities of the several fields, it will cause an unbalanced stress on the armature and its shaft, under which it will bend, and as this bending is continually reversed relatively to the fibres of the shaft, they will eventually become weakened and give way. Especially is this likely to take place in dynamos with short air-gaps, wherein any difference in the lengths of the air-gaps produces a much greater percentage difference in the flux-density than in dynamos with long air-gaps. In toothed armatures with short air-gaps the shaft must on this account be sufficiently strong to withstand the stress without appreciable bending.

Reference has already been made to the importance in dynamo design of the predetermination of the flux due to a given number of ampere-turns wound on the field-magnet, or, conversely, of the number of ampere-turns which must be furnished by the exciting coils in order that a certain flux corresponding to one field The magnetic circuit.may flow through the armature core from each pole. An equally important problem is the correct proportioning of the field-magnet, so that the useful flux Za may be obtained with the greatest economy in materials and exciting energy. The key to the two problems is to be found in the concept of a magnetic circuit as originated by H. A. Rowland and R. H. M. Bosanquet;[16] and the full solution of both may be especially connected with the name of Dr J. Hopkinson, from his practical application of the concept in his design of the Edison-Hopkinson machine, and in his paper on “Dynamo-Electric Machinery.”[17] The publication of this paper in 1886 begins the second era in the history of the dynamo; it at once raised its design from the level of empirical rules-of-thumb to a science, and is thus worthy to be ranked as the necessary supplement of the original discoveries of Faraday. The process of predetermining the necessary ampere-turns is described in a simple case under Electromagnetism. In its extension to the complete dynamo, it consists merely in the division of the magnetic circuit into such portions as have the same sectional area and permeability and carry approximately the same total flux; the difference of magnetic potential that must exist between the ends of each section of the magnet in order that the flux may pass through it is then calculated seriatim for the several portions into which the magnetic circuit is divided, and the separate items are summed up into one magnetomotive force that must be furnished by the exciting coils.

|

| Fig. 29. |

The chief sections of the magnetic circuit are (1) the air-gaps, (2) the armature core, and (3) the iron magnet.