1911 Encyclopædia Britannica/Plough and Ploughing

PLOUGH AND PLOUGHING. To enable the soil to grow good crops the upper layer must be pulverized and weathered. This operation, performed in the garden by means of the spade, is carried on in the field on a larger scale by the plough,[1] which breaks the soil and by inverting the furrow-slice, exposes fresh surfaces to the disintegrating influence of air, rain and frost.

The first recorded form of plough is found on the monuments of Egypt, where it consists simply of a wooden wedge tipped with iron and fastened to a handle projecting backwards and a beam, pulled by men or oxen, projecting forwards. Many references to the plough are found in the Old Testament, notably that in 1 Sam. xiii. 20: “All the Israelites went down to the Philistines to sharpen every man his share and his coulter.” Descriptions of ploughs found in Hesiod’s Works and Days and in Virgil’s Georgics i. 169–175, show little development in the implement. The same may be said of the Anglo-Saxon ploughs. These are shown with coulter and share and also with wheels, which had in earlier times been fitted to ploughs by the Greeks and also by the natives of Cis-Alpine Gaul (Pliny, Hist. nat. 18, 18). A mattock with which to break the clods is often found represented in Anglo-Saxon drawings as subsidiary to the plough. All these types of plough are virtually hoes pulled through the ground, breaking but not inverting the soil. In the first half of the 18th century a plough with a short convex mould-board of wood was introduced from the Netherlands into England and, as improved at Rotherham in Yorkshire, became known as the Rotherham plough and enjoyed considerable vogue. At this period ploughs were made almost wholly of wood, the mould-board being cased with plates of iron. Small, of Berwickshire, brought out a plough in which beam and handle were of wrought iron, the mould-board of cast iron. The shares, when made of the same material, required constant sharpening, this necessity was removed by the device, patented by Robert Ransome in 1803, of chilling and so hardening the under-surface of the share; the upper surface, which is soft, then wears away more quickly than the chilled part, whereby a sharp edge is always assured. Nowadays the mould-board is of steel with a chilled and polished surface to give greater wearing qualities and to reduce friction. In the latter part of the 19th century there were numerous improvements but no fundamental alterations in the construction of the ordinary plough.

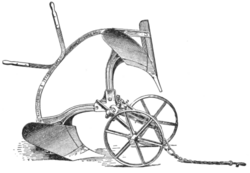

The working parts of the plough are the coulter, the share, and the breast or mould-board. These are carried on the beam, to which are attached the handles or tilts at the back, and the hake or clevis and draught-chain at the front. The hake is notched so that, by moving the draught-chain higher or lower thereon, the plough is caused to go more or less deeply into the ground. It may also be adjusted to suit the height of the horses used. The hake moves laterally on a quadrant and it is thus possible to give the plough a tendency to left or right by moving the hake in the reverse direction. A frame is bolted to the beam and this carries the breast or mould-board to the fore-end of which the share is fitted. The side-cap, a plate of iron fixed to the land-side of the frame, is intended to keep the edge of the unploughed soil vertical and prevent it from falling into the furrow. A piece of iron called the slade is bolted to the bottom of the frame, and this, running along the sole of the furrow, acts as a base to the whole implement. The coulter (either knife or disk) and sometimes a skim-coulter (or jointer) are attached adjust ably to the beam, so as to act in the front of the share.

Newcastle Plough.

The coulter is a knife or revolving disk which is fixed so that its point clears the point of the share. The skim-coulter is shaped like a miniature plough, substituted for or fixed in front of the coulter; it is used chiefly on lea land, to pare off the surface of the soil together with the vegetation thereon, and turn it into the previous furrow, where it is immediately buried by the furrow slice. Two wheels of unequal height are commonly fitted to the front of the beam. By means of them the depth and width of the furrow are regulated, whereas in the case of “swing” or wheelless ploughs these points depend chiefly on the skill of the ploughman. In the wheeled plough some of the weight and downward pull due to its action on the ground is taken by the wheels; the sliding friction is thus to some extent converted into a rolling friction, and the draught is correspondingly diminished.

|

|

| Crested Furrow. | Rectangular Furrow. |

In operation the coulter makes a perpendicular cut separating the furrow-slice which is divided from the “sole” of the furrow by the share and then inverted by the curve of the breast as the plough moves forward. The process is indicated in the illustration of different types of furrow. The form of a furrow is regulated by the shape and width of the share, working in combination with a proper shaped breast. A “crested” furrow is obtained by the use of a share, the wing of which is set at a higher altitude than the point, but this type of furrow is less generally found than the “ rectangular ” form obtained by a level-edged share, which leaves a flat bottom.

Wide Broken Furrow.

Digging Plough.

During the greater part of the 19th century the ideal of ploughing was to preserve the furrow-slice unbroken, and this object was attained by the use of long mould-boards which turned the slices gently and gradually, laying them over against one another at an angle of 45°, thus providing drainage at the bottom of the furrow, and exposing the greatest possible surface to the influences of the weather. Subsequently the digging plough came into vogue; the share being wider, a wider furrow is cut, while the slice is inverted by a short concave mould-board with a sharp turn which at the same time breaks up and pulverizes the soil after the fashion of a spade. Except on extremely heavy soils or on shallow soils with a subsoil which it is unwise to bring upon the surface, the modern tendency is in favour of the digging plough.

A ploughed field is divided into lands or sections of equal width separated by furrows. On light easy draining land 22 yds. is the usual width; on the heaviest lands it may be as little as 5 yds., and in the latter case the furrows will act as drains into which the water flows from the intervening ridges.[2]

Turnwrest Plough.

Certain important variations of the ordinary plough demand consideration. The one-way plough lays the furrows alternately to its left and right, so that they all slope in the same direction. This is found advantageous on hill-sides where the work is easier if all the furrows are turned downhill; or from another point of view the furrows may be all laid uphill so as to counteract the tendency for the soil to work down the slope. One-way ploughs also leave the land level and dispense with the wide open furrows between the ridges which are left by the ordinary plough. They are made on different principles. One type comprises two separate ploughs, one right hand and one left, which revolve on the beam, one working, while the other stands vertically above it. In another the mould board and share are shaped so that they can be swung on a swivel under the beam when the latter is lifted. A third type is made on the “ balance ” principle, two plough beams with mould-boards being placed at right angles to one another, so that while the right-hand plough is at work the left-hand is elevated above the ground.

Balance Plough.

Double-furrow or multiple ploughs are a combination of two or more ploughs arranged in echelon so as to plough two or more furrows. The weight of these implements necessitates some provision for turning them at the headlands, and this is supplied either by a bowl wheel, enabling the plough to be turned on one side, or by a pair of wheels cranked so that they can be raised by a lever when the plough is working. The double-furrow plough was known as early as the 17th century, but, till the introduction of the latter device by Ransome in 1873, cannot be said to have been in successful use.

Riding Plough.

The “sulky” or riding plough is little known in the United Kingdom, but on the larger arable tracts of other countries where quick work is essential and the character of the surface permits, it is in general use. In this form of plough the frame is mounted on three wheels, one of which runs on the land, and the other two in the furrow. The furrow wheels are placed on inclined axles, the plough beam being carried on swing links, operated by a hand lever when it is necessary to raise the plough out of the furrow. The land wheel and the forward furrow wheel are adjustable vertically with reference to the frame, for the purpose of controlling the action of the plough.

In the disk plough, which is built both as a riding and a walking plough, the essential feature is the substitution of a concavoconvex disk, pivoted on the plough beam, for the mould-board and share of the ordinary plough. This disk is carried on an axle inclined to the line of draught, and also to a vertical plane. As the machine is drawn forward the disk revolves and cuts deeply into the ground, and by reason of its inclination crowds the earth outwards and thus turns a furrow. A scraper is provided to keep the disk clean and prevent sticking. The controlling levers and draught arrangements are similar to those in the “sulky” plough. The advantage of this plough over the ordinary form is in the absence of sliding friction, and in the mellow and porous condition in which it leaves the bottom of the furrow.

Multiple Disk Plough.

Disk ploughs are unsuitable for heavy sticky soils and for stony land, but may be used with effect on stubbles and on land in a dry hard state. Perhaps their most common use is in ploughing on a large scale in conjunction with steam power.

Steam is employed as motive power when it is necessary to plough large areas in a short time. In the United Kingdom steam ploughing is generally carried on on the double-engine system (introduced by Messrs John Fowler about 1865), in which case two sets of ploughs are arranged on the one-way balance principle, so that while one set is at work the other is carried clear of the ground. In this arrangement, a pair of locomotive engines, each having a plain winding drum fixed underneath the boiler, are placed opposite to each other at the ends of the field to be operated upon; the rope of each of the engines is attached to the plough, or other tillage implement, which is drawn to and fro betwixt them by each working in turn. While the engine in gear is coiling in its rope and drawing the plough towards itself, the rope of the other engine is paid out with merely so much drag on it as to keep it from kinking or getting ravelled on the drum.

American Steam Plough.

In the United States and elsewhere engines drawing behind them a number of ploughs, arranged in echelon and taking perhaps 30 ft. at a time, are frequently seen. On smaller areas petrol motors with one or more ploughs attached are sometimes used.

There is a large variety of ploughs which differ in their purpose from the ordinary plough.

The ridging plough is an implement with a mould-board on each side, terminating in front in a flat point, and used for moulding up potatoes, and for throwing up the ridge on which to plant roots.

The sub-soil plough has the beam and body but not the mould-board of an ordinary plough. Following in the furrow of an ordinary plough it breaks through the sub-soil to a depth of several inches, making it porous and penetrable by plant roots.

Gripping and draining ploughs are employed in opening the grips and trenches necessary both in surface and underground drainage.

See Davidson and Chase, Farm Motors and Farm Machinery; articles in L. H. Bailey's Cyclopedia of American Agriculture (New York, 1907) and Standard Encyclopaedia (London, 1908), &c.

- ↑ The O. Eng form is ploh, which is usually found in the sense of “plough-land,” a unit for the assessment of land (see Hide), the regular O. Eng. word for the implement being sulh, still found in some dialects in the form sull. It appears in many Teutonic languages, cf. Du. ploeg, Ger. Pflug, Swed. plog, Dan. plov. The Slavonic forms, such as Russ. or Pol. plug, are borrowed from the German. It does not appear in Gothic, where the word used is hoha. The ultimate origin of “plough” is unknown. Max-Muller (Science of Language, i. 296) connects the word with the Indo-European root meaning “to float,” seen in the Gr. πλοτον, a boat or ship; the same word would be applied to the ship “ploughing” through the waves, and to the implement “ploughing” through the earth. A Celtic origin has been suggested, connecting the word with Gael. ploe, stump of a tree, as forming the original plough. The form “plow” was common in English until the beginning of the 18th century, and is usual in America.

- ↑ Methods of the “setting-out” of land to be ploughed together with a full discussion of other technical details relating to ploughing will be found in ch. vii. of W. J. Malden's Workman’s Technical Instructor (London, 1905).