SHIPBUILDING. When ships were built of wood and propelled by sails their possible size and proportions were limited by the nature of the structural material, while the type of structure had been evolved by long experience and was incapable of any radical modification. Speed depended so much on circumstances independent of the design of the vessel, such as the state of the wind and sea, that it was impossible to include a definite speed over a voyage or measured distance as one of the essential requirements of a design; and the speed actually obtainable was low even under the most favourable conditions when judged by modern standards. Stability depended principally on the amount of ballast carried, and this was determined experimentally after the completion of the vessel. Under these conditions there was no room for any striking originality of design. One vessel followed so closely on the lines of another, that the qualities of the new ship could be determined for all practical purposes by the performance of an almost identical vessel in the past. The theoretical science of shipbuilding, the object of which is to establish quantitative relations between the behaviour and performance of the ship and the variations in design causing them, was generally neglected.

With the introduction of iron, and later of steel, as a structural material for the hulls of ships, and of heat engines for their propulsion, the possible variation of size, proportions and propelling power of ships was enormously increased. In order to make the fullest use of these new possibilities, and to adapt each ship, as closely as may be, to the special purpose for which it is intended, theoretic knowledge has become of paramount importance to the designer. He has been forced to investigate closely those branches of the abstract physical sciences that bear specially on ships and their behaviour, and these mathematical and experimental investigations constitute the study of Theoretical Shipbuilding. It embraces the consideration of problems and questions upon which the qualities of a ship depend and which determine the various features of the design, having regard to the particular services that the ship will be required to perform; i.e. the requirements that must be fulfilled in order that she may make her various passages economically and with safety in all conditions of wind and sea, the best form for the hull with regard to the resistance offered by the water and the engine power requisite in order to attain the speed desired, the nature of waves and their action upon the ship, and the structural arrangements necessary in order that she may be sufficiently strong to withstand the various stresses to which she will be subjected. The determination of the most suitable dimensions to fulfil certain conditions involves the consideration of a different set of circumstances for almost every service; and here the experience gained in vessels of similar type, together with the known effect of modifications made to fulfil new conditions of each particular design, can be used as a guide. The requirements of economical working, safety, &c., determine the length, breadth, depth and form. The length has a most important bearing on the economy of power with which the speed is obtained; and on the breadth, depth and height of side, or freeboard, depend to an important degree the stability and seaworthiness of the vessel.

While, however, the importance to the ship designer of mathematical theories based on first principles and experiment can hardly be overrated, it should be observed that the circumstances and conditions postulated are invariably much less complex than those which surround actual ships. The applicability of the theories depends on the closeness with which the assumed circumstances are realized in practice. The ultimate guide in the design of new ships must, therefore, still remain practical experience. To this experience theory is a powerful assistance, but can by no means replace it.

Theoretical Shipbuilding

Stability.

When a ship floats at rest in still water, the forces acting upon her must be in equilibrium. These consist of the weight of the ship acting vertically downwards through its centre of gravity and the resultant pressure of the water on the immersed hull. If the ship be supposed removed and the cavity thus formed filled with water, then, since this volume of water Equilibrium.is in equilibrium under the same system of fluid pressures, the resultant of these pressures must be equal and opposite to the weight of the water in the cavity and will therefore act vertically upwards through the centre of gravity of this portion of water. Defining the weight of water displaced by the ship as the displacement, and its centre of gravity as the centre of buoyancy, it is seen that the fundamental conditions for the equilibrium of a ship in still water are (a) that the weight of the ship must be equal to the displacement, and (b) that its centres of gravity and buoyancy must be in the same vertical line.

A floating ship is always subject to various external forces disturbing it from its position of equilibrium, and it is necessary to investigate the stability of such a position, i.e. to determine whether the ship, after receiving a small disturbance, will tend to return to its former position, in which case its equilibrium is termed stable, or whether, Stability of equilibrium. on the other hand, it will tend to move still farther from the original position, when the equilibrium is termed unstable. The intermediate case, when the ship tends to remain in its new position, is a third state of equilibrium, which is termed neutral.

Of the modes of disturbance possible, it is evident that a bodily movement of the ship in a horizontal direction or a rotation about a vertical axis will not affect the conditions of equilibrium; the equilibrium is also stable for vertical displacements of a ship. The remaining movements, viz. rotations about a horizontal axis, can be resolved into rotations in which the displacement is unaltered, and vertical displacements, the effect of the latter being considered separately. Of the various horizontal axes about which a ship can rotate two are of particular importance, viz. (1) an axis parallel to the longitudinal plane of symmetry, (2) an axis at right angles to this plane, both axes being so chosen that the displacement remains constant; the stability of a ship with reference to rotations about these axes is known as the transverse stability and the longitudinal stability respectively. In the following account the consideration of stability is confined at first to these two cases; the general case of rotation about any horizontal axis whatever being dealt with later.

|

Fig. 1. |

Let fig. 1 represent a transverse section of a ship, WL being its water line when upright, and W′L′ its water line when inclined to a small angle θ as shown.Transverse stability.

Assuming that the displacement is unaltered, if G be the position of the ship’s centre of gravity and B, B′ the positions of its centre of buoyancy in the upright and inclined positions respectively, the forces acting on the ship consist of its weight W vertically downwards through G and the resultant water pressure equal to W acting vertically upwards through B′. These constitute a couple of moment W×GZ where Z is the foot of the perpendicular from G on to the vertical through B′; the direction of the couple as drawn in the figure is such as would cause the ship to return to its original position, i.e. the equilibrium is stable for the inclination shown.

If M be the intersection of the vertical through B′ with the original vertical, the moment of the restoring couple is equal to W×GM sin θ, and GM sin θ is termed the righting lever.

If, by moving weights on board, G be moved to a different position on the original vertical through B, the original position of the ship will remain one of equilibrium, but the moment of stability at the angle of inclination θ will vary with GM. If G be brought to the position G′ above M the moment W×G′Z′ will tend to turn the ship away from the original position. It follows that the condition that the original position of equilibrium shall be stable for the given inclination is that the centre of gravity shall be below the intersection of the verticals through the upright and inclined centre of buoyancy; and the moment of stability is proportional to the distance between these two points.

When the inclination θ is made smaller the point M approaches a definite position, which, in the limit when θ is indefinitely small, is termed the metacentre.

In ships of ordinary form it is found that for 10 to 15 degrees of inclination, the intersection of the verticals through the centres of buoyancy B and B′ remains sensibly at the metacentre M; and therefore within these limits the moment of stability is approximately equal Small inclinations.to W×GM sin θ.

Since the angle on either side of the vertical within which a ship rolls in calm or moderate weather does not usually exceed the limit above stated, the stability and to a great extent the behaviour of a vessel in these circumstances are governed by the distance GM which is known as the metacentric height. The position of G can be calculated when the weights and positions of the component parts of the ship are known. This calculation is made for a new ship when the design is sufficiently advanced to enable these component weights and their positions to be determined with reasonable accuracy; in the initial stages of the design an approximation to the vertical position of G is made by comparison with previous vessels.

|

Fig. 2. |

The position of the centre of gravity of a ship is entirely independent of the form or draught of water, except so far as they affect the amount and distribution of the component weights of the ship. The position of the metacentre, on the other hand, depends only on the geometrical properties of the immersed part of the ship; and it is determined as follows:

Let WL, W′L′ (fig. 2) be the traces of the upright and inclined water planes of a ship on the transverse plane, B, B′ the corresponding position of the centre of buoyancy; θ the angle of inclination supposed indefinitely small in the limit, and S the intersection of WL and W′L′; join BB′.

By supposition the displacement is unchanged, and the volumes WAL, W′AL′ are equal; on subtracting W′AL it is seen that the two wedges WSW′, LSL′ are also equal. If dx represent an element of length at right angles to the plane of the figure, y1, y2, the half-breadths one on each side at any point in the original water line, so that WS=y1, SL=y2, the areas WSW′, LSL′ differ, from 12y12.θ, 12y22.θ by indefinitely small amounts, neglecting which the volumes of WSW′, LSL′ are equal to ∫12y12θdx and ∫12y22θdx.

Since these are equal we have

;

i.e. the moments of the two portions of the water plane about their line of intersection passing through S are equal. This line is also the axis of rotation, which therefore passes through the centre of gravity of the water plane. For vessels of the usual shape, having a middle line plane of symmetry and floating initially upright, for small inclinations consecutive water planes intersect on the middle line.

Again if g1, g2 are the centres of gravity of the wedges WSW′, LSL′, and v the volume of either wedge, the moment of transference of the wedges v×g1g2 is equal to the moment of transference of the whole immersed volume V×BB′ where V is the volume of displacement.

But v×g1S=moment of wedge WSW′ about S=13∫y13.θ.dx, and v×Sg2=moment of wedge LSL′ about S=13∫y23.θ.dx. Adding, 13∫(y13+y23)θ.dx=v×g1g2=V×BB′. But BB′=M.θ to the same order of accuracy, and 13∫(y13+y23).dx is the moment of inertia of the water plane about the axis of rotation; denoting the latter by I, it follows that BM=I/V; i.e. the height of the metacentre above the centre of buoyancy is equal to the moment of inertia of the water plane about the axis of rotation divided by the volume of displacement. These quantities, and also the position of the centre of buoyancy can be obtained by the approximate methods of quadrature usual in ship calculations, and from them the position of the metacentre can be found.

If the ship is wholly immersed, or if the inertia of the water plane is negligible as in a submarine when diving, BM=O, and the condition for stability is that G should be below B; the righting lever at any angle of inclination is then equal to BG sin θ.

During the process of design the position of the centre of gravity is determined by the disposition of hull material and fittings, machinery, coal and all other movable weights, the position of which is necessarily fixed by other considerations than those of stability; but the height of the metacentre above the centre of buoyancy varies approximately as the cube of the breadth, and any desired value of GM is readily obtained by a suitable modification in the beam.

The metacentric height in various typical classes of ships at “normal load” is as follows:—

| Class of ship. | Approximate GM in Ft. |

| First class battleship and cruiser | 312 to 5 |

| Second and third class cruiser and scout | 2 to 3 |

| Torpedo boat destroyer | 112 to 212 |

| First class torpedo boat | 1 to 112 |

| Steam picket boat or launch | .8 to 112 |

| River gunboat (shallow draught) | 8 to 20 |

| Large mail and passenger steamer | .5 to 2 |

| Cargo steamer | 1 to 2 |

| Sailing ship | 2 to 6 |

| Tug | 112 to 212 |

The metacentric height adopted in steamships is governed principally by the following considerations:—

(a) It should be sufficiently large to provide such a position of G as will give ample stability at considerable angles of inclination and sufficient range.

(b) Where ample stability at large angles is obtained by other means, the stability at small angles, which is entirely due to the metacentric height, should be sufficient to prevent forces due to wind on upper works, movement of weights athwartships, turning, &c., causing large and uncomfortable angles of heel.

(c) It should be sufficient to allow one or more compartments to become opened to the sea, through accidental damage, without risk of capsizing.

(d) It should, if possible, be sufficiently large in the normal condition of the ship to permit the greatest possible freedom in the stowage of a miscellaneous cargo without producing instability.

(e) On the other hand an excessive value causes rapid and uncomfortable rolling among waves.

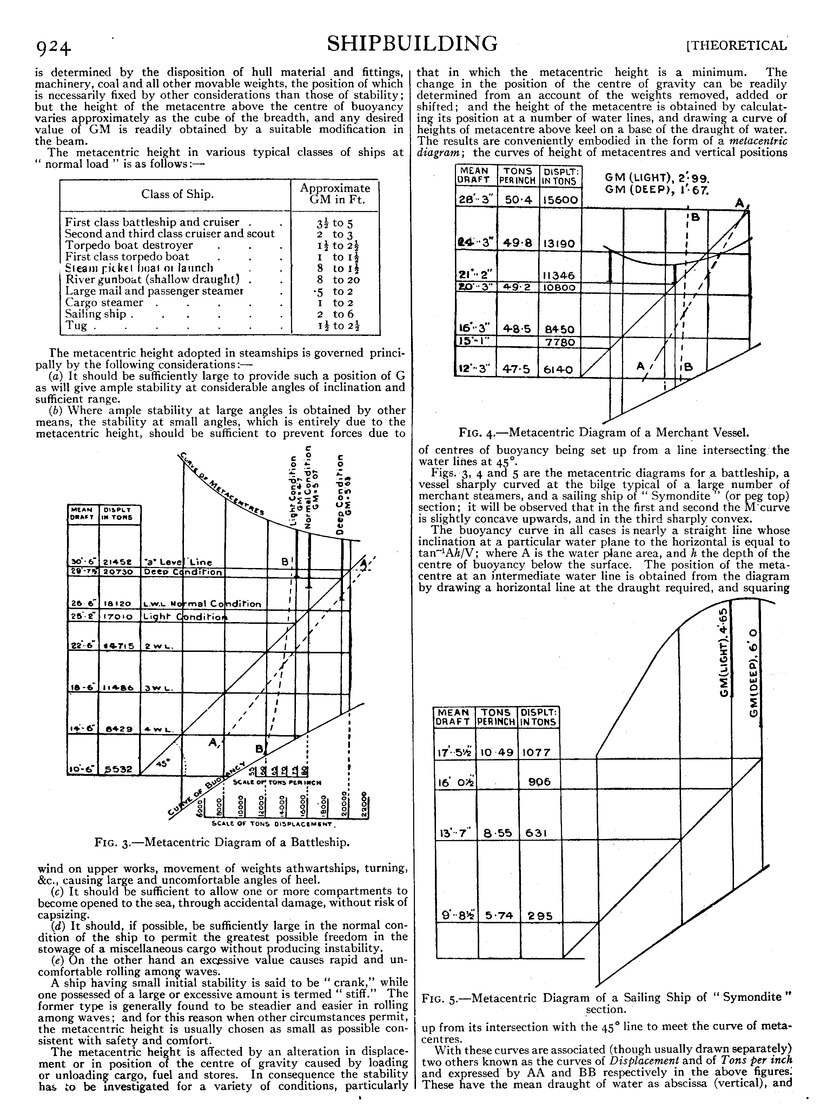

Fig. 3.—Metacentric Diagram of a Battleship.

A ship having small initial stability is said to be “crank,” while one possessed of a large or excessive amount is termed “stiff.” The former type is generally found to be steadier and easier in rolling among waves; and for this reason when other circumstances permit, the metacentric height is usually chosen as small as possible consistent with safety and comfort. The metacentric height is affected by an alteration in displacement or in position of the centre of gravity caused by loading or unloading cargo, fuel and stores. In consequence the stability has to be investigated for a variety of conditions, particularly that in which the metacentric height is a minimum. The change in the position of the centre of gravity can be readily determined from an account of the weights removed, added or shifted; and the height of the metacentre is obtained by calculating its position at a number of water lines, and drawing a curve of heights of metacentre above keel on a base of the draught of water. The results are conveniently embodied in the form of a metacentric diagram; the curves of height of metacentres and vertical positions of centres of buoyancy being set up from a line intersecting, the water lines at 45°.

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

- Fig. 4.—Metacentric Diagram of a Merchant Vessel.

Figs. 3, 4 and 5 are the metacentric diagrams for a battleship, a vessel sharply curved at the bilge typical of a large number of merchant steamers, and a sailing ship of “Symondite” (or peg top) section; it will be observed that in the first and second the M curve is slightly concave upwards, and in the third sharply convex.

The buoyancy curve in all cases is nearly a straight line whose inclination at a particular water plane to the horizontal is equal to tan−1Ah/V; where A is the water plane area, and h the depth of the centre of buoyancy below the surface. The position of the metacentre at an intermediate water line is obtained from the diagram by drawing a horizontal line at the draught required, and squaring up from its intersection with the 45° line to meet the curve of metacentres.

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

- Fig. 5.—Metacentric Diagram of a Sailing Ship of “Symondite”

section.

With these curves are associated (though usually drawn separately) two others known as the curves of Displacement and of Tons per inch and expressed by AA and BB respectively in the above figures. These have the mean draught of water as abscissa (vertical), and the displacement in tons and the number of tons required to increase the mean draught by 1 in., respectively, as ordinates (horizontal). The ordinate on the curve of displacement at any water line is clearly proportional to the area of the curve of tons per inch up to that water line.

The properties of the metacentric stability at small angles are used when determining the vertical position of the centre of gravity of a ship by an “inclining experiment”; this gives a check on the calculations for this position made in the initial stages of the design, and enables the stability of the completed ship in any condition to be ascertainedInclining experiment. with great accuracy.

The experiment is made in the following manner:—

Let fig. 6 represent the transverse section of a ship; let 𝑤, 𝑤 be two weights on deck at the positions P, Q, chosen as far apart transversely as convenient; and let G be the combined centre of gravity of ship and weights. When the weight at P M is moved across the deck to Q′, the centre of gravity of the whole moves from G to some point G′ so that GG' is parallel to PQ′ (assumed horizontal) and equal to ℎ𝑤/W where ℎ is the distance moved through by P, and W is the total displacement. The ship in consequence heels to a small angle θ, the new vertical through G passing through the metacentre M; also GM=GG′ cot θ=ℎ−𝑤/W cot θ, the metacentric height being thereby determined and the position of G then found from the metacentric diagram. In practice θ is observed by means of plumb bobs or a short period pendulum recording angles on a cylinder;[1] the weight 𝑤 at P, which is chosen so as to give a heel of from 3° to 5°, is divided into several portions moved separately to Q′. The weight at Q′ is replaced at P, the angle heeled through again observed; and the weight at Q similarly moved to P' where P′Q=ℎ=PQ′, and the angle observed; GM is then taken as the mean of the various evaluations.

Fig. 6.

In the case of small transverse inclinations it has been assumed that the vertical through the upright and the inclined positions of the centre of buoyancy intersect, or, which is the same thing, that the centre of buoyancy remains in the same transverse plane when the vessel is inclined. This assumptionLarge inclinations. is not generally correct for large transverse inclinations, but is nevertheless usually made in practice, being sufficiently accurate for the purpose of estimating the righting moments and ranges of stability of different ships, calculated under the same conventional system; this is all that is necessary for practical purposes.

With this assumption, there will always be a point of intersection (M′ in fig. 7) of the verticals through the upright and inclined centres of buoyancy; and the righting lever is, as before, GZ=GM′ sin θ. In this case, however, there is no simple formula for BM′ as there is for BM in the limiting case where θ is infinitesimal; and other methods of calculation are necessary.

The development of this part of the subject was due originally to Atwood, who in the Philosophical Transactions of 1796 and 1798, advanced reasons for differing from the metacentric method which was published by Bouguer in his Traité du navire in 1746. Atwood's treatment of stability (which was the foundation of the modes of calculation adopted in England until about twenty years ago) was as follows:—

Let WL, W′L′ (fig. 7) be respectively the water lines of a ship when

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

- Fig. 7.

upright and inclined at an angle θ, S their point of intersection: B and B′ the centres of buoyancy, 𝑔1 and 𝑔2 the centres of gravity of the equal wedges WSW′, L′SL, and ℎ1, ℎ2 the feet of the perpendiculars from 𝑔1 and 𝑔2 on the inclined water line. Draw GZ, BR parallel to W'L', meeting the vertical through B′ in Z and R.

The righting lever is GZ as before; if V be the volume of displacement, and 𝑣 that of either wedge, then

V × BR=𝑣 × ℎ1ℎ2

also

GZ=BR−BG sin θ;

whence the righting moment or

W×GZ=W𝑣×ℎ1ℎ2V −BG sin θ .

This is termed Atwood's formula. Since BG, V and W are usually known, its application to the computation of stability at various angles and draughts involves only the determination of 𝑣×ℎ1ℎ2. A convenient method of obtaining this moment was introduced by F. K. Barnes and published in Trans. Inst. N.A. (1861). The steps in this method were as follows: (a) assume a series of trial water lines at equal angular intervals radiating from S′ the intersection of the upright water line with the middle line plane; (b) calculate the volumes of the various immersed and emerged trial wedges by radial integration, using the formula

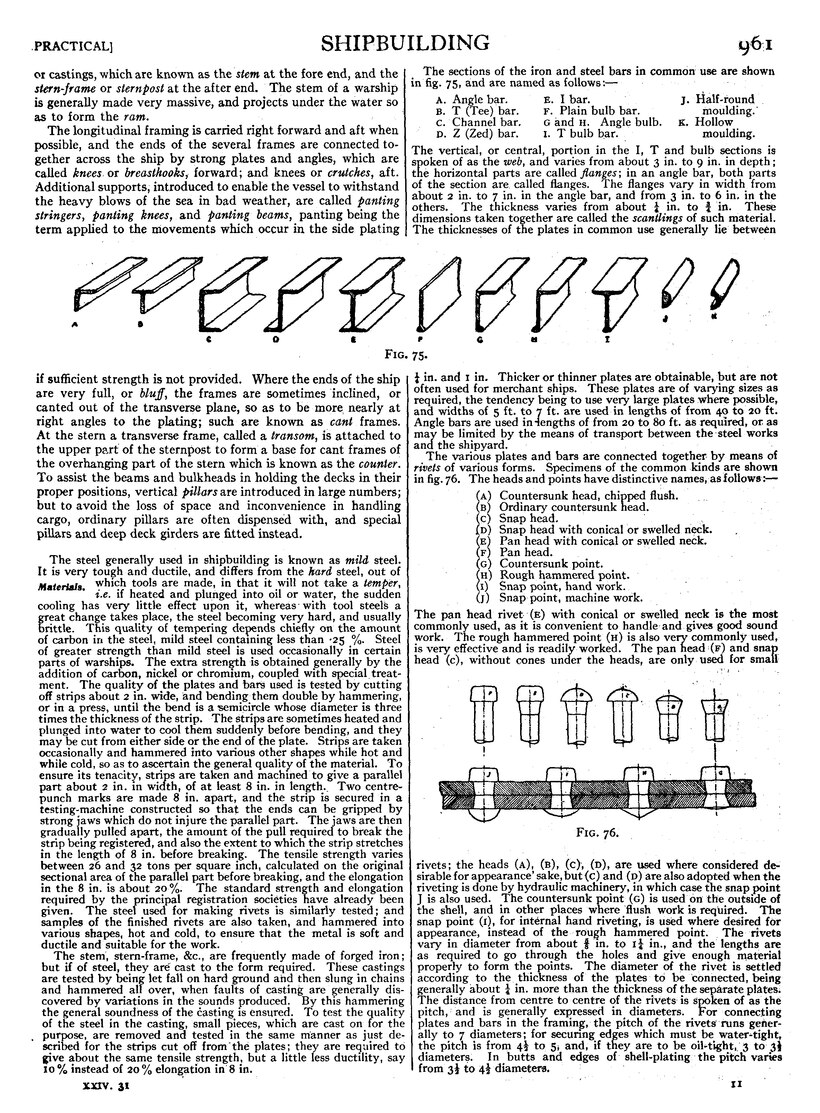

𝑣=12𝑑φ∫𝑟2dx,

where 𝑟, φ are the polar co-ordinates of the ship’s side, measured from S′ as origin, and dx an element of length; (𝑐) estimate the moment of transference of the same wedges parallel to the particular trial water line by the formula

𝑣×ℎ1ℎ2=13cos(φ−φ)𝑑φ∫𝑟3𝑑𝑥,

adding together the moments for both sides of the ship; and (𝑑) add or subtract a parallel layer at the desired inclination to bring the result to the correct displacement. The true water line at any angle is obtained by dividing the difference of volume of the two wedges by the area of the water plane (equal to ∫𝑟𝑑𝑥, for both sides) and setting off the quotient as a distance above or below the assumed water line according as the emerged wedge is greater or less than the immersed wedge. The effect of this “layer correction” on the moment of transference is then allowed.

The righting moment and the value of GZ are thus determined for the displacement under consideration at any required angle of heel.

A different method of obtaining the righting moments of ships at large angles of inclination has prevailed in France, the standard investigation on the subject being that of M. Reech first published in his memoir on the “Construction of Metacentric Evolutes for a Vessel under different Conditions of Lading” (1864). The principle of his method is dependent on the following geometrical properties:—

Let B′, B″ (fig. 8) be the centres of buoyancy corresponding to two water lines W′L′, W″L″ inclined at angles θ, θ+𝑑θ, to the original upright water line WL, 𝑑θ being small; and let 𝑔1, 𝑔2 be the centres of gravity of the equal wedges W′TW″, L′TL″. The moment of either wedge about the line 𝑔1𝑔2 is zero, and the moments of W′L′A and FIG. 8. of W″L″A about 𝑔1𝑔2 are therefore equal; since these volumes are also equal, the perpendicular distances of B′ and B″ from 𝑔1𝑔2 are equal, or B′B″ is parallel to 𝑔1𝑔2.

The projection on the plane of inclination of the locus of the centre of buoyancy for varying inclinations with constant displacement is termed the curve of buoyancy, a portion BB′B″ of which is shown in the figure. On diminishing the angle 𝑑θ indefinitely so that B″ approaches B′ to coincidence, the line B′B″ becomes, in the limit, the tangent to the curve BB′B″, and 𝑔1𝑔2 coincides with the water line W′L′; hence the tangent to the curve of buoyancy is parallel to the water line.

Again, if the normals to the curve at B′, B″ (which are the verticals corresponding to these positions of the centre of buoyancy) intersect at M′, and those at B″, B″′ (adjacent to B″) at M″, and so on, a curve may be passed through M′, M″, . . . , commencing at M, the metacentre. This curve, which is the evolute of the curve of buoyancy, is known as the metacentric curve, and its properties were first investigated by Bouguer in his Traité du Navire. The points M′M″, . . . on the curve are now termed pro-metacentres.

If ρ represent the length of the normal B′M′ or the radius of curvature of the curve of buoyancy at an angle θ, then ρ.𝑑θ = 𝑑𝑠 the length of an element of arc of the B curve. In the limit when dθ is indefinitely small, 𝑑𝑠𝑑θ=ρ. Using Cartesian co-ordinates with B as origin and B𝑦, B𝑧, as horizontal and vertical axes, we have—

| 𝑑𝑦𝑑θ=𝑑𝑠𝑑θcos θ=ρ cos θ, | (1) |

| 𝑑𝑧𝑑θ=𝑑𝑠𝑑θsin θ=ρ sin θ, | (2) |

whence

and the righting lever GZ =𝑦 cos θ+(𝑧−BG) sin θ.

The radius ρ is (as for the upright position) equal to the moment of inertia of the corresponding water-plane about a longitudinal axis through its centre of gravity divided by the volume of displacement; the integration may be directly performed in the case of bodies of simple geometrical form, while a convenient method of approximation such as Simpson’s Rules is employed with vessels of the usual ship-shaped type. As an example in the case of a box, or a ship with upright sides in the neighbourhood of the water-line, if BG=𝑎 and BM =ρ0, then ρ=ρ0 sec3θ; whence

𝑦=ρ cos θ.𝑑θ=ρ0 tan θ,

𝑧=ρ sin θ.𝑑θ=12ρ0 tan2 θ,

and

GZ=(ρ0−𝑎) sin θ0+12ρ0 tan2 θ.sin θ;

which relations will also hold for a prismatic vessel of parabolic section. It is interesting to note that in these cases if the stability for infinitely small inclinations is neutral, i.e. if p0=a, the vessel is stable for small finite inclinations, the righting lever varying approximately as the cube of the angle of heel.

The application of the preceding formulae to actual ships is troublesome and laborious on account of the necessity for finding by trial the positions of the inclined water-lines which cut off a constant volume of displacement. To avoid this difficulty the process was modified by Reech and Risbec in the following manner z-Multiply equations (1) and (2) by V.dθ, V being the volume of displacement; we then have—

| 𝑑(V𝑦)=I cos θ.𝑑θ, | (3) |

| 𝑑(V𝑧)=I sin θ.𝑑θ, | (4) |

where I is the moment of inertia of the inclined water-line about a longitudinal axis passing through its centre of gravity. These formulae have been obtained on the supposition that the volume V is constant while θ is varying; but by regarding the above equations as representing the moments of transference horizontally and vertically due to the wedges, it is evident that V may be allowed to vary in any manner provided that the moment of inertia I is taken about the longitudinal axis passing through the intersection of consecutive water-lines. In particular the water-lines may all be drawn through the point of intersection of the upright water-line with the middle line, and the moments of inertia are then equal to 13∫𝑟3𝑑𝑥 for both sides of the ship, 𝑟 being the half-breadth along the inclined water-line; the increase in volume is the difference between the quantity ∫𝑑θ∫12𝑟2𝑑𝑥 for the two sides of the ship.

If Vα, V0 be the volumes of displacement at angles α and θ respectively,

| Vα−V0=dθ[12𝑟2𝑑𝑥 difference] |

(5) |

and substituting in (3) and (4) and integrating

| Vα𝑦=dθ[13𝑟2𝑑𝑥 sum]sin θ |

(6) |

| Vα𝑧=dθ[13𝑟2𝑑𝑥 sum]cos θ |

(7) |

On eliminating Vα in (5), (6) and (7), 𝑦 and 𝑧 can be found.

This is repeated at different draughts, and thus Vα, 𝑦 and 𝑧 are determined at a number of draughts at the same angle, enabling curves of 𝑦 and 𝑧 to be drawn at various constant angles with V for an abscissa; from these, curves may be obtained for 𝑦 and 𝑧 with the angle α as abscissa for various constant displacements; GZ being equal to

𝑦 cos α+(𝑧−𝑎) sin α.

From the foregoing it is evident that the elements of transverse stability, including the co-ordinates of the centre of buoyancy, position of pro-metacentre, values of righting lever and righting moment. depend on two variable quantities—the displacement and the angle of heel. The righting lever GZ is in England selectedCurve of stability. the most useful criterion of the stability, and, after being evaluated for the various conditions, is plotted in a form of curves—(a) for various constant displacements on an abscissa of angle of inclination, (b) for a number of constant angles on an abscissa of displacement.

Fig. 9.—Cross Curves of Stability of a Battleship.

These are known as curves of stability and cross curves of stability respectively; either of these can be readily constructed when the other has been obtained; which process is utilized in the method now almost universally adopted for obtaining GZ at large angles of inclination, a full description being given in papers by Merrifield and Amsler in Trans. I.N.A. (1880 and 1884). The procedure is as follows:

1. The substitution of calculations at constant angle for those at constant volume. A number of water-lines at inclinations having a constant angular interval (generally 15°) are drawn passing through the intersection S′ of the load water-line with the middle line on the body plan. Other water-lines are set off parallel to these at fixed distances above or below the original water-line passing through S′.

2. The volumes of displacement and the moments about an axis through S′ perpendicular to the water-line are determined for each draught and inclination by means of the Amsler-Laffon integrator, the pointer of this instrument being taken in turn round the immersed part of each section.

Fig. 10.—Curves of Stability of a Battleship.

3. On dividing the moments by the corresponding volumes, the perpendicular distance of the centre of buoyancy from the vertical through S′ is obtained, i.e. the value of GZ, assuming G and S′ to coincide.

4. For each angle in turn “cross curves” of GZ are drawn on a base of displacement. 5. From the cross curves, curves of stability on a base of angle of inclination can be constructed for any required displacement, allowance being made for the position of G by adding to, or subtracting from, each ordinate, the quantity GS′ sin α according as G is below or above S′.

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

Fig.11.—Curves of Stability of a Merchant Vessel.

A typical set of cross curves of stability for a battleship of about 18,000 tons displacement is shown in fig. 9. It will be observed that the righting levers decrease with an increase of displacement; and this is a general characteristic of the cross curves for ships of ordinary form. The additional weights that constitute the difference between light and deep load (i.e. cargo, coal, stores and water) are generally placed low down, and thus the position of the centre of gravity is usually lower when loaded than when light, causing an increase of stability which frequently more than compensates for the loss of stability indicated by the cross curves.

The stability curves for the same vessel are reproduced in fig. 10. It is customary in warships to draw separate curves for three conditions: (a) normal load, i.e. fully equipped with bunkers about half full, and reserve feed tanks empty; (b) deep load with all bunkers and tanks full; (c) light with all coal, water (except in boilers), ammunition, provisions and consumable stores removed.

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

Fig. 12.—Curves of Stability of a Box-shaped Vessel showing the influence of, beam and freeboard.

The curves for a cargo or passenger ship are generally drawn for the condition when light, when full laden with assen ers or with a homogeneous cargo, and sometimes for an intermediate condition; typical curves are given in fig. 11.

Stability curves are obtained on the assumptions—

1. That all openings in the upper deck, forecastle and poop (if any) are covered in and made watertight; and the buoyancy of any erections above these decks is generally neglected.

2. That the side of the ship is intact up to the upper deck, all side scuttles, ports or other openings being closed.

3. That all weights in the ship are absolutely fixed.

4. That no changes of trim occur during the inclination.

In some cases curves are drawn (a) with forecastle and poop intact, (b) with these thrown open to the sea, the latter condition being more commonly considered.

The slope of the stability curve for small angles, the maximum righting lever with the angle at which it occurs, and the range or the inclination at which the stability vanishes are of particular interest, inasmuch as the curve depends principally on these features; and the effect on them, particulars of variation of freeboard,” breadth and position of centre of gravity, is considered below.

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

- Fig. 13.—Curves of Stability of “Monarch” and “Captain.”

The stability curve AA (fig. 12) is drawn for a box-shaped vessel of draught 10 ft., freeboard 10 ft. and beam 30 ft.; with C.G. in the water-plane. The curves EE, FF, GG are drawn for the same vessel, but with freeboard altered to 1212, 712 and 5 ft. respectively; it will be observed that freeboard has no influence on the stability at small angles, but has a marked effect on the range and maximum righting lever. An increase of freeboard is generally accompanied by a rise in the position of the centre of gravity; this is not included in the curves, but would actually reduce the stability to. some extent. The effect of freeboard on the range and on the safety of ships is also illustrated by a comparison between the curves of stability (fig. 13) of the armoured turret ships “Monarch” and “Captain,” the latter of which was lost at sea in 1870. These vessels were similar in construction and dimensions except that the freeboard of the “Monarch” was 14′ 0″ and that of the “Captain” 6′ 6″; the smaller freeboard of the “Captain” was associated with a slightly lower position of the centre of gravity and a greater metacentric height. The stability curve of the “Captain” in consequence rises rather more steeply than that of the “Monarch” up to about 14° when the deck edge is immersed; the righting lever then rapidly declines, and vanishes at 5412°, in contrast to, the “Monarch’s,” where the maximum righting lever is doubled and range augmented 1.3 times by the additional freeboard. For the influence of the' range in enabling a ship to withstand a suddenly applied force see “Dynamical Stability.”

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

- Fig. 14.—Curves of Stability of a Steam Yacht showing effect

- of variation in height of centre of gravity.

Again, for the box-shaped vessel previously considered, if the breadth is modified successively from 30 ft. to 35, 25 and 20 ft., other features remaining unaltered, the curves of stability then obtained are represented by BB, CC and DD in fig. 12. It is seen that alteration in beam affects principally the stabilityEffect of beam. levers at moderate angles of inclination, while at 90° inclination the curves all intersect. Since at small angles GZ=GM.θ (in circular measure) approximately, the initial slope of the curve is proportional to GM, and the tangent to this curve at the origin can be drawn by settinog by the value of GM as an ordinate to an angle of one radian (57.3°) as abscissa, and joining the point to the origin. (See figs. 10 and 11.) The height of the meta centre above the centre of buoyancy will, caeteris paribus, vary with the cube of the breadth, and an increase of beam will result in a large increase of stability at moderate angles.

Finally the effect of an alteration in the vertical position of the centre of gravity is illustrated by the three stability curves of a steam yacht in fig. 14, where the centre of gravity is successively raised 1 ft. In the condition corresponding to the fourth and lowest curve, the GM is negative (−.2 ft.)Effect of position of C.G. and so also are the righting levers up to 15° when the curve crosses the axis; from 15 to about 52° the GZ is positive, but above that value it again becomes negative. In this case the stability is unstable at the upright position, and the ship will roll to an angle of 15° on either side where the equilibrium is stable. This peculiarity is not uncommon in merchant steamers at light draught. Ample stability at large angles and good range is provided in such cases by high freeboard; but, apart from any considerations of safety, Water ballast is used to lower the centre of gravity to a sufficient extent to avoid excessive tenderness.

The properties of the loci of centres of buoyancy and of prometacentres were fully investigated by Dupin in 1822, including also the surfaces into which these curves develop when admitting inclinations about transverse and “skew” axes. It has been shown that the tangent to the curve of buoyancyGeometrical properties. at any point is parallel to the corresponding water-line; and assuming that the ship is only free to turn in a plane perpendicular to the axis of inclination, the positions of equilibrium are found by drawing from the centre of gravity all possible normals to the buoyancy curve, or equally, all possible tangents to its evolute, the metacentric curve, since the condition to be satisfied is, that the centres of gravity and buoyancy shall lie in the same vertical. Again, when the curve of statical stability crosses the axis, making an acute positive angle as at P in fig. 14, the values of GZ on either side of P are such as to tend to move the ship towards the position at P, and the equilibrium at P is stable. Similarly, when the curve crosses the axis “negatively,” as at the origin and Q, the equilibrium is unstable. Since the angle of intersection cannot be either positive or negative twice in succession, on considering rotation in one direction only, it follows that positions of stable and unstable equilibrium occur alternately and the total number of positions of equilibrium is even.

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

Fig. 15.—Metacentric, Buoyancy and Flotation Curves of “Serapis.”

The radius of curvature of the curve of buoyancy is equal to I/V, and is always positive. The curve, therefore, has no re-entrant parts or cusps, is continuous and has no sudden changes in direction; parallel tangents (or normals) can be drawn through two points only (corresponding to inclinations separated by 180°), which property is shared by its evolute, the metacentric curve. On the other hand, the moment of inertia I varies continuously with the inclination, attaining maximum and minimum values alternately; and the metacentric curve, therefore, contains a series of cusps corresponding to the values of I when dI=0, which will generally occur at positions of symmetry (e.g. at 0° and 180°), near the angles at which the deck edge is immersed or emerged, and at about 90° and 270°.

The curves of buoyancy and flotation and the metacentric curve for H.M. troopship “Serapis” are shown with reference to the section of the ship in fig. 15, and on an enlarged scale for greater clearness in fig. 16.[2] It will be seen that the metacentric curve contains eight cusps, M1, M2, . . . M8. Assuming the ship to heel to starboard, M1 corresponds to the upright position, M2 to the immersion of the starboard topsides and emersion of the port bilge; M3 corresponds to 90° of heel, M4 to the complete immersion of the deck and the emersion of the starboard bilge. M5 corresponds to the bottom-up position and similarly for M6, M7 and M8. There are also 6 nodes, of which P and Q are on the middle line. By means of those curves, the effect of a rise or fall in the position of the ship’s centre of gravity can readily be traced. The positions of equilibrium correspond- to the normals that can be drawn from G to the buoyancy curve, or equally to the tangents drawn to its evolute the metacentric curve. For stable equilibrium G lies below M, i.e. generally between B and M; and for unstable equilibrium, similarly, B is between G and M. In the ship under consideration, G1 was the actual centre of gravity, and G1M1 corresponds to the upright position of stable equilibrium. As the vessel heels over, equilibrium (this time unstable) is again reached at about 90°, and a third position (stable) is obtained when the vessel is bottom up, G1M5 being then the metacentric height. A fourth (unstable) position is obtained at about 270°, after which the original position G1M1 is reached, the vessel having turned completely round. For this position of G1 therefore, there are four positions of equilibrium, two of which are stable and two unstable; and this is also true for all positions of G between M1 and M5.

If G lies at G4 between M5 and the point P, there are six positions of equilibrium, alternately stable and unstable. If G is below P as at G5, there are two positions of equilibrium of which the upright only is stable.” A self-righting life-boat exactly corresponds to this condition, the vessel being capable of resting only in the original upright position. If G is above Q, on the other hand, as at G3, there are again only two positions of equilibrium, the vessel being unstable when upright. If G is at G2 there are again six positions of equilibrium; the upright position is unstable, but a stable position is reached at a certain angle on either side. This phase is often realised in merchant ships when light, as already stated (vide fig. 14). When G is exactly upon one of the branches of the metacentric curve, the equilibrium is neutral; if it is at M1 the ship is stable for finite inclinations, and if at Q unstable; similarly for M5 (except that the neutral state is then reached, at 180°) and for P.

In all the above cases it will be observed that the positions of stable and unstable equilibrium are equal in number and occur alternately. There are two exceptions:—

1. When the moment of inertia of the water plane changes abruptly so that the B curve receives a sudden change of curvature. This is possible with bodies of peculiar geometrical forms, and two positions of M then correspond to one position of the body; if G lies between them, the equilibrium is stable for inclinations in one direction and tins tab lien for 'those in the opposite direction, and is then termed mixed.

2. When the equilibrium is neutral, this condition may be regarded as the coincidence of two or more positions of equilibrium alternately stable and unstable. The ship may then be either stable, unstable or neutral for finite inclinations; in exceptional cases she may be stable in one direction and unstable in the other, resembling to some extent the condition of “mixed equilibrium.”

Another curve whose properties were originally investigated by Dupin is the curve of flotation F1F2F3 . . (fig. 15), which is the envelope of all the possible water-lines for the ship when inclined transversely at constant displacement. Since, as previously shown, consecutive water-planes intersect on a line passing through their centre of gravity, or, as it is termed, the centre of flotation, the curve of flotation will be the locus of the projections of the centres of flotation on the plane of the figure, which curve touches each waterline.

From consideration of the slope of a ship's side around the periphery of a water-line, Dupin obtained the following expression for ρ, the radius of curvature of the curve of flotation,

ρ′ = fy2 tan α. dsarea of water-planefor both sides,

where ds is an element of the perimeter, α the inclination of the ship's side to the vertical, and y its distance from the longitudinal axis through the centre of flotation. M. Emile Leclert, in a paper read at the Institution of Naval Architects, 1870, proved the e uivalence of the above formula to the two following, which are (known as Leclert's Theorem:

ρ′=ρ+VdρdV and ρ′=dIdV,

where I and V are respectively the moment of inertia of the water plane and the volume of displacement, and ρ is the radius of the curve of buoyancy or B′M′. Independent analytical proofs of the formulae were given in the paper referred to; and (Trans. I.N.A., 1894) a number of elegant geometrical theorems in connexion with stability, given by Sir A. G. Greenhill, include a demonstration of Leclert's Theorem as follows (in abbreviated form):

Let B, B1 (fig. 17) be the centres of buoyancy of a ship in two consecutive inclined positions, and F, F, the corresponding centres of flotation. Draw normals BM, BIM, meeting at the pro-meta centre M, and FC, FiC, meeting at the centre of curvature C. Produce FB, F1B, to meet at O; join OM, MC.

Then BM, CF and B1M, CF, are respectively parallel, and ultimately also BB1 , FF1, ; hence the triangles MBB1, CFF1 are similar and

BMCF=BB1FF1=OBOF,

so that O, M and C are collinear.

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

Fig. 17.

If the displacement V be now increased by dV, changing B to B′, and M to M′, then since the added displacement dV may be supposed concentrated at F, B' will lie on OBF, and it may be shown similarly as before that M' lies on OC. Further, considering the transference of moments, BB′×V=BF×dV.

Draw MED parallel to BF, then

dVV=BB′BF=MEMD=M′ECD=dρρ′−ρ;

∴dρdV=ρ′−ρV or ρ′=+VdρdV,

giving Leclert's first expression; also, since ρ = IV,

dIdV=ρ+VdρdV=ρ′,

which is Leclert's second expression for p'.

The value of ρ′ at the upright can be obtained from the meta centric diagram by the following simple construction. Let M and B be the meta centre and the centre of buoyancy for a water-line WL on the metacentric diagram (fig. 18); draw the tangent to the B curve meeting WL at Q, and through Qdraw QR to meet MB and parallel to the tangent to the M curve at M.

Let BP=h, and area of water-line be A. Then

PQ=h cot θ=hVAh=VA;

also

MR=BM−(BP+PR)=ρ−VA (tan θ+tan φ).

If D be the draught,

tan θ+tan φ =dρdD = −A.dρdV,

whence

MR=ρ+VdρdV=ρ′

the curve of flotation being concave upwards if R is below M.

For moderate inclinations from the upright, the buoyancy of the added layer due to a small additional submersion will act through the centre of curvature of the curve a of flotation; this point may be regarded as that at which any additional weight will, onf being placed on a ship, cause no difference to the values of the righting moment at moderate angles of inclination. The curve of flotation, therefore, and its evolute bear similar relations to the increase or decrease of the stability of a ship due to alteration of draught, as the curves of buoyancy and of pro-metacentres do to the actual amount of the stability.

The curve of flotation resembles the curve of buoyancy in that not more than two tangents can be drawn to it in any given direction, but it differs in that its radius of curvature can become infinite or change sign. It contains a number of cusps determined by ρ′=dIdV=O. These occur in an ordinary ship-shape body at positions: (1) at or near the angles at which the deck is immersed or emerged (four in number); and (2) at or near the angles 90° and 270°. There are, therefore, six cusps in the curve ¢ of flotation of an ordinary ship; they are shown in figs. 15 and 16 by the points F2, F3, F4, F6, F7, F8.

The following relations between the curves of buoyancy and of pro-meta centres and the curve of statical stability are of interest, and enable the former curves to be constructed when the latter have been obtained. If GZ′, GZ″ (fig. 19) are the righting levers correspond in to inclinations θ, θ+ dθ, where dθ vanishes in the limit; B′, B″, the centres of buoyancy, metacentre; produce GZ' to meet, B″M′ in U.

Then, neglecting squares of small quantities,

d(GZ′)=Z′U=M′Z′.dθ,

or vertical distance of M′ above G=d(GZ′)dθ.

Also M′B′=M′B″;

hence

Z″B″−Z′B′=MZ′-MZ″=Z″U=GZ′.dθ,

or

GZ=B′Z′dθ,

i.e. the vertical distance (B′Z′) of G over B is equal to ∫GZ.dθ.

It follows that by differentiating the levers of statical stability and finding the slope at each ordinate the vertical distance of M′ over G is obtained, and M′ may be plotted by setting up this value from Z′ above GZ′ drawn at the correct inclination; also that by integrating the curve of statical stability and finding its area up to any angle, the vertical separation of G and B′ is obtained, and B′ may be plotted by setting down this value increased by BG below Z′.

The work done in inclining a ship slowly so as to maintain a constant displacement (and avoid communicating any unnecessary movement or disturbance to the water) is given by the expression where M is the moment resisting the inclination. This may be writtenDynamical stability.

and it has been shown above that this is equal to the weight multiplied by the vertical separation of the centres of gravity and buoyancy. This is otherwise evident since the work is the sum of that done against the forces acting on the ship, viz. the weight and the buoyancy; these are respectively equal to W×rise of G, and W×fall of B, giving the value W.(Z′B′−BG) as before.

The dynamical stability of a ship at any angle is defined as the work done in inclining the ship from the upright position; and its value is conveniently obtained by integrating the curve of statical stability as stated above. The dynamical stability can thus be calculated at various angles and a curve obtained, whose ordinates represent work done in foot-tons. The curve of dynamical stability is drawn for a battleship (normal condition) in fig. 10, and is there shown in relation to the curve of statical stability; it will be seen that the dynamical stability increases continuously until the righting moment vanishes, when it becomes a maximum.

A formula for the dynamical stability of a ship at any angle was given by Canon Moseley in a paper read before the Royal Society in 1850. Experiments on models made under his direction at Portsmouth Dockyard showed that the actual work in quickly inclining to a moderate angle agreed closely with that calculated in the case of a model of circular section; but considerable divergence was obtained with a model of triangular section owing to the motion of the water set up, and also, probably, to the variation in displacement during the roll.

The existence of large righting couples at moderate angles of heel is of greater importance in a sailing ship than in a steamship, since in the former it determines the amount of sail that can be safely carried under known weather conditions and thereby influences the speed. A sailing ship in motion is subjected to the wind-pressures on the sails and the upper works of the ship, and to the water-pressures on the hull. When the ship is in steady motion, these forces are equal and opposite; and, so far as the stability is concerned, it is sufficient to determine the transverse resultant of the wind-pressure on the sails, and its moment, the water-pressure on the hull affecting only the speed and leeway of the ship.

The pressure on the sails depends on their form and area, their position, and the apparent velocity of the wind, i.e. the velocity relative to the ship. The pressure of the wind on the hull is obtainable similarly to that on the sails, but is usually neglected as the heeling moment is small. Experiments have been made to determine the wind-pressure on plates by Dines, Langley, Eiffel, Stanton and others; and the results of the experiments are briefly as follows—

The normal pressure R in pounds on a plate of area A square feet exposed to face normally a wind of velocity V feet per second is given b the formula R=KAV2, where K is a coefficient depending on the form and area of the plate. For a square or circular plate of about 1 sq. ft. in area K is about .0014, corresponding to a pressure of 1 ℔ per sq. ft. at about 16 knots. The coefficient increases slightly for larger dimensions of the plate. It has also been found that a departure from the square or circular form involving an increase in perimeter for the same area causes an increase in the mean pressure. An alteration from the plane to the concave, analogous to the “bellying” of sails, is accompanied by a slight, increase in the pressure per square foot of projected area; but for any large amount of concavity the increase is more than counterbalanced by the decrease in the projected area.

No simple law exists connecting the normal pressure on a plate exposed obliquely to the wind with the angle of incidence; it is found that the results for air exhibit a close agreement with those for water after allowing for the difference of density between the two fluids. At small angles of incidence up to about 20°, or even 40° (varying with the shape of the plate), the pressure varies, directly as the angle; beyond this limit it is slightly diminished, afterwards increasing or decreasing to a value which is almost constant for the remaining angles up to and including 90°. The centre of pressure for oblique impact lies between the leading edge and the centre of gravity of the area. In a plate 1 ft. square, it lies 0.3 ft. from the leading edge at 10° inclination and 0.4 ft. at 30° inclination, gradually approaching the centre of the plate as the angle of inclination is increased. A slight curving or concavity of the plate does not appear to have much influence on the normal component of the wind pressure.

The wind-pressure on the sails of a ship cannot be calculated with any degree of precision because existing information is insufficient to take account of (a) the variety in area and shape of the sails used; (b) the different positions in which the sails may be placed relative to the wind and to each other; and (c) the interference of adjacent sails with each other. On the other hand, conclusions based on these experiments are of value both in assisting in an intelligent appreciation of the effects of changes in the sail areas, sail positions, and in the form of rig, and in forming a comparison between the various qualities of speed, stability and general behaviour of vessels with which experience has been obtained.

The stability of a sailing vessel is usually estimated by assuming all plain sail to be placed in a fore and aft direction and to be subject to a normal pressure of 1 ℔ per sq. ft., corresponding to a wind of about 16 knots. The resultant pressure of the wind is supposed to act through the centre of gravity of the total sail area (termed the centre of ejort). The resultant pressure of the water on the hull, which is equal and o posite to the wind-pressure, is assumed to pass through the centre of) gravity of the area of the immersed middle line plane (termed the centre of lateral resistance). If h be the vertical distance between these points ir1 feet, A the sail area in square feet, and α the angle of heel, the moment causing the heel is (on these assumptions)

Ah2240foot-tons

and the righting moment is approximately

W×GM sin α.

Hence

sin α=Ah2240.W×GM.

The reciprocal of this quantity or

2240.W×GMAh

is a measure of the capability of the ship to stand up under her canvas and is termed the power to carry sail. Its value varies with different sizes and classes of ships and boats. It is relatively small in small boats and small yachts owing to the practicability of reducing the angle of heel by movable ballast; and a low value is also permissible in large yachts on account of their great range of stability. In-boats and yachts it varies from 3 to 4 and in full-rigged sailing ships from 15 to 20.

The stability of sailing vessels at large angles of inclination varies considerably with the class of vessel. In racing yachts and other completely decked sailing boats whose ratios of beam to depth and draught are comparatively small, initial stability is obtained by lowering the centre of gravity with ballast fitted on the keel, and-the range then extends to considerably over 90°; on the other hand, a number of half-decked or open sailing boats immerse their gunwales when inclined to a moderate angle. With reference to this, Mr Dixon Kemp in his Yacht Architecture remarks that the deck edge should not be immersed at an angle of heel less than 20°; some small centre-board boats whose gunwales are awash at 12° or 15° cause anxiety. With full-rigged sailing ships this angle is commonly 20° to 25.

The effect of a sudden gust of wind on a sailing ship is obtained by equating the work done on the ship by the gust to her dynamical stability; and the angle at which this equality holds will be the extreme angle of heel, assuming the ship to be originally upright and at rest. Since the dynamical stability is represented by the area of the statical stability curve it is convenient to represent this angle in relation to this latter curve. The effects of the resistance and inertia of the water and any change of displacement are neglected; the wind-pressure is assumed constant during the roll, in accordance with the results of experiments on oblique lates (the maximum angle of roll being supposed less than 50°); the modification of the pressure due to the motion of the sail is also neglected.

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

- Fig 20.

Let OPQ (fig. 20) be the curve of statical stability, the ordinates representing righting moments, and let the heeling couple due to the gust be represented by OS. If N be the extreme angle of heel, draw SPUR parallel to the base, cutting the curve at P, R; and PM, NQ perpendicular. The work done by the wind is the area OSUN and is equal to the dynamical stability of the ship or the area OPQN. Hence the areas OPS, PQU are equal, and the extreme angle of heel is determined by this equality. If P and Q lie on the initial and approximately straight portion of the curve, the extreme angle of heel ON is about twice that of the steady angle OM corresponding to the strength of the gust. The area QUR represents the reserve dynamical stability when the wind is blowing with strength corresponding to OS; the intercepts of the ordinates below SPUR doing work against the force of the wind, leaving the segments above SPR available for absorbing the kinetic energy possessed by the vessel at the position of steady heel PM. As the strength of the gust is increased the points P and Q travel farther along the curve until P′, Q′ are reached, such that the areas P′Q′Q, OTP′ are equal; the vessel will then come momentarily to rest at Q′ and will be in unstable equilibrium, any increase in the wind-pressure causing her to capsize. It follows that a ship sailing in a wind of sufficient strength to cause a moderate angle of heel equal to OM′ will be on the point of capsizing if the wind should happen to drop and afterwards return suddenly with its former force, A more dangerous, though improbable, case in which a gust of wind strikes the ship just as she has completed a roll to windward' can similarly be investigated; it is found that the safe angle of steady heel under this condition is considerably less than that represented by OM′. It thus appears that it is of the-greatest importance that sailing vessels should possess large dynamical stability in order to provide against the risk of capsizing due to fluctuations in the wind-pressure. Although the neglect of the wind and water resistances in the above investigation materially modifies the quantitative results, the general conclusions point to the necessity for sufficient range and freeboard however large the righting levers may be at small inclinations.

The centres of effort and of lateral resistance have not the same longitudinal position, consequently horizontal couple is produced which turns the vessel either into the wind or away from it. In the former condition the vessel is said to be “ardent,” and in the latter to be “slack.” In order that a vessel maybe quick in going about and yet not require too large a helm angle on a straight course, she should be slightly “ardent,” i.e. the true centre of effort should be slightly abaft the true centre of lateral resistance; The assumed and true positions of these centres differ to some extent, and on making allowance for this it is found that in the majority of vessels possessing slight ardency the assumed C.E. lies slightly before instead of abaft the assumed C.L.R. In small sailing boats the points are usually very near together but in a large number of sailing ships, including H.M. sloops, their distance apart is about .05 L, and in yachts' about .02 L, where L is the length.

It may be noted in this connexion that the area of sail spread and the size of the ship are often connected by the coefficient AW23 known as the Driving Power, The, value for small sailing boats and for yachts is about 200, and for- full-rigged sailing ships from 80 to 100 (including plain sail only).

The method of estimating the: righting moment of a ship when inclined from a position of equilibrium through a small angle in the longitudinal plane is exactly analogous to that used in the case of small transverse inclination, and similar propositions are true in both cases, viz.:—

1. Consecutive water-lines intersect about an axis passing through the centre of flotation.

2. The height of the longitudinal meta centre M above the centre of buoyancy is equal to the moment of inertia about this axis divided by the volume of displacement of the ship.

3. The righting moment at any small angle of inclination θ (circular measure) is equal to

W.GM.θ

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

Fig. 21.

In fig. 21 let WL be the water-line corresponding to the positions G and B, and conceive a longitudinal movement of a portion of the weights in the ship causing G to move horizontally to G′. If G′ be abaft G the ship will alter trim by the stern until B moves to B′ vertically beneath G′ and the water-line changes to W′L′, intersecting WL at the centre of flotation F.

If L be the length of the ship between the draught marks, the change of trim (WW′+LL′) is equal to L.θ, and the moment changing trim is W.GG′ or W.GM.θ: the change of trim in inches (other linear dimensions being in feet) is therefore

The change of trim due to any horizontal movement of weights is therefore equal to the moment of the shift of weight divided by the quantity

W×GM12×L

which is the moment required to change trim one inch. Since the longitudinal moment of inertia of the Water-plane includes the cube of the length as a factor, the longitudinal BM is usually large compared with BG, and the moment to change trim 1 in. in foot-tons is nearly equal to

which is approximately constant for moderate variations of draught.

If a weight of moderate amount 'w tons be placed at a distance of a feet abaft the centre of flotation F, the bodily sinkage in inches is wT, the moment changing trim by the stern is wa foot-tons, and the change of trim is therefore waM where T is the “tons per inch” and M the moment to change trim 1 in. If b be the distance of F abaft the middle of length, the draughts forward and aft are increased respectively by

w (1T−aM ⋅ L+2b2L)

and

w (1T+aM L−2b2L) inches.

A ship provided with' water-tight compartments is liable to have

water admitted into any of them on account of damage

received, or may require to carry water or other fluid in

bulk as ballast or cargo. The effect of this addition on the LY en d

draught and the stability is therefore of interest. ThereStability when damaged.

are three cases:—

1. When the water completely fills a compartment;

2. When the water partially fills a compartment up to the level of

the water-line, remaining in free communication with the sea; and

3. When a compartment is partially filled with water without any

communication with the sea.

In the first case the water is regarded as a weight added to the ship; the mean sinkage is obtained from the displacement curve, the change of trim from the “moment to change trim,” and the angle of heel from the metacentric diagram, or (for large angles) the cross curves. In general, if the compartment filled is low in the ship, the stability is increased; if high, it is diminished.

In the second case, assume in the first place the compartment to be amidships, so that no heel or change of trim occurs, and to be moderate in siie, so that the sinkage is moderate in amount.

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

Fig. 22.

Let ABCD (fig. 22) be such a compartment bounded by; watertight bulkheads sufficiently high to prevent water reaching adjoining compartments. Let the water-lines be WEFL, W′GHL′, before and after bilging; let A, a be the area of the whole water-plane WEFL and of the portion EF within the compartment respectively, in square feet; and let v be the volume contained in EBCF diminished by the volume of any solid cargo in the compartment;, The buoyancy is reduced by ans amount v by bilging, and the amount added through sinking must be equal to the amount so-lost. If x be the sinkage in feet, then

v=x(A−a),

so that the mean sinkage is equal to the buoyancy lost divided by the area of the intact water-plane. In the event of the compartment being so situated as to cause heel and change of trim, the mean sinkage is first determined as above, and the effect of heel and change of trim superposed.

To obtain the heel produced, the position of the centre of flotation for the intact portion of the water-plane is, found, and thence the vertical and horizontal positions of the new centre of buoyancy. are deduced by takingateount of the buoyancy lost through bilging, and then regained by the layer between the two water-planes. The moment of inertia of the intact water-plane is found about an axis through the new centre of flotation and thence the height of the new meta centre M′ determined. The heel θ (assumed small) is found by equating the horizontal shift of B to sin θ× the vertical distance of M′ above G, both being equal to the moment causing heel divided by the displacement.” Tn a similar manner the change of trim is obtained. If the compartment bilged is large so that considerable changes in its area and that of the ship at the water-line result, the sink age and alteration in stability are found by a tentative process, closer approximations to the final water-line being successively made.

An investigation of the stability when bilged at or near the waterline is, of“special importance in warships owing to their liability to damage by gunfire in action, with the consequent opening up of a large number of compartments to the sea. Calculations are made of the sinkage and stability when the unarmoured or lightly armoured parts of the ship are completely riddled; the stability should be sufficient to provide for this contingency.

The third case, where the ship is intact but has compartments partially filled with water or other liquid, is of frequent occurrence. Practical illustrations occur in connexion with the filling and emptying of water-ballast and oil-fuel tanks, and particularly in the case of ships fitted to carry large quantities of oil in bulk.

Let fig. 23 represent the section of a vessel fitted with a tank PQRS partly full of water. Let WL, wl be the upright water-lines

of the vessel and tank, G the centre of gravity of the vessel and

water combined, B the centre of buoyancy of the vessel, and b the

centre of gravity of the Water.,

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

Fig. 23.

As the ship is inclined successively through angles θ1, θ2, . . . the centre of buoyancy B moves along the curve of buoyancy to B1, B2, . . . the normals at which are tangential to the metacentric curve M1 M1, . . . those at small angles passin through the meta centre M. If the water in the tank could be kept from moving as the inclination roceeded, G would be fixed in the ship, and the righting levers would be GZ1, GZ;, those at small angles being equal to GM sin θ. Actually, if the inclination be slowly performed, the water-level in the tank changes successively to w1l1, w2l2, . .maintaining a level surface at all times; its centre of gravity moves to b1, b22, . . . thereby causing a corresponding alteration in the combined centre of gravity G. Drawing bn, bn, perpendicular to the verticals through b1, b2, . . and calling w, W the weights of the water and of the water and ship combined, then at the angle θ2 the line of action of the weight of the water w has moved through a distance bn and the righting moment of the ship is diminished by an amount w×br2. It is evident that the movement of the centre of gravity of the water in the tank is the same as would be the movement of the C.B. of a ship having the same form as the tank and water-lines corresponding to wl, w1l1, w2l2, &c. The values of the levers br1, br2. . .can therefore be obtained by a process similar to that used for obtaining the righting levers of the ship; cross curves and thence ordinary stability curves being drawn for various heights of water and inclinations. If θ1 be a small angle of inclination, the line of action of the weight b1m will be such as to pass through the metacentre m corresponding to the water-line wl, and determined by the formula bm=iv where i is the moment of inertia of the water-plane wl about a longitudinal axis through its centre of gravity and v the volume of water contained. The moving weight w at b may therefore be replaced by an equal weight fixed at m, which is the virtual centre of gravity of the water; and the centre of gravity G of ship and water is likewise raised to a virtual position G′ where

GG′=wW⋅bm=vV ⋅ iv=iV.

If the tank contain a fluid of specific gravity p the virtual rise of the centre of gravity is ρiV. The loss of stability at small angles due to the mobility of the water is thus independent of the quantity in the tank, but is proportional to the moment of inertia of its free surface. It is possible for a small quantity of water with an extensive free surface to render a ship unstable in the upright condition; the angle to which this large loss of stability extends depends, however, on the quantity of water in the tank, for the extent of the sideways movement of the centre of gravity G of ship and water is minute if the tank be either nearly empty or nearly full, and the loss of stability at all angles above a small amount will then be inappreciable; the loss at moderate angles is usually a maximum when the tanks are about half full.

The assumption made above, viz. that the ship is inclined so gradually as to maintain a level water surface in the tank, is by no means in accordance with the actual circumstances during rol ing; waves are then set up in the water, causing it to wash from side to side. so that the loss of stability may be either more or less than the amount calculated. To avoid danger of capsizing in still water, large tanks in a ship are filled or emptied in succession as far as possible, so that not more than one or two are partly full at the same time. Water-tight longitudinal partitions are also fitted in wide tanks in order to reduce the moment of inertia of the free surface. On the other hand tanks, partly filled with water, have been fitted and found effective in certain ships in order to reduce the rolling oscillations among waves. (See § Rolling.)

Hitherto the stability of a ship has been considered only with reference to inclinations, about either a longitudinal or transverse axis. These are the only cases which it is necessary to deal with in practice for the purpose of ascertaining the probable qualities as re rds stability of a vessel by comparing the elements (fits stability in the design stage with those of existing ships Whose qualities have been tested by experience. For the exact theoretical consideration of the stability of a ship or any floating body, however, it is necessary to take account of the true line of the action of the buoyancy and not merely of its projection on the plane of inclination. The development of this part of the subject has largely been due to M. Dupin in his Mémoire de la stabilité des corps flottants and to M. Guyou in his Théorie du navire. If a ship is inclined in all possible positions, keeping the displacement constant, the locus of the centre of buoyancy is a closed surface which is known as the surface of buoyancy; the curve of buoyancy for two-dimensional inclinations being, the projection on the plane of 'rotation of the corresponding points on the surface of buoyancy. Similarly the envelope of all the water-planes is defined as the surface of flotation. The stability of a ship in all positions is known when (a) the forms and dimensions of the surface of buoyancy, and (b) the position of the centre of gravity relative to it, have been obtained; the former depends entirely on the geometrical form of the ship and on the constant volume of displacement assumed, and the latter has reference only to the arrangement and magnitude of the component weights of the structure and lading. For an infinitesimal inclination the line joining the centres of buoyancy when upright and inclined is parallel to the water-plane, and the tangent plane to the surface of buoyancy is therefore parallel to the water-plane, i.e. it is horizontal, and the normal to the surface is vertical. If the initial position is one of equilibrium, the centre of gravity must lie on the normal. To determine the effect of a small disturbance from the position of equilibrium, it is necessary, as in the particular inclinations already considered, to find the line of action of the buoyancy for adjacent positions, Le. to trace the normals to the surface of buoyancy. Consecutive normals to this surface will not, in general, intersect; but, from the properties of curvature of surfaces, there are two particular directions of inclination for which adjacent normals to the surface will intersect the original normal, these directions being perpendicular to one another and parallel to the principal axes of the indicatrix of the surface of buoyancy.

An image should appear at this position in the text. If you are able to provide it, see Wikisource:Image guidelines and Help:Adding images for guidance. |

Fig. 24.

If fig. 24 be a plan of the water-plane, Ox1 the axis of inclination passing through O the centre of flotation, Oy and Oz perpendicular axes in and at right angles to the plane of flotation, then, from a consideration of the wedges of immersion and emersion for a small inclination 0, the travel o the centre of buoyancy B becomes:—

θV∬y′2.dx′.dy′ (or BB1, in fig. 24) parallel to Oy

θV∬y′.dx′.dy′ (or—BB1) parallel to Ox

and

12θ2V∬y′2.dx′.dy′ (or B2B′)parallel to Oz.

These may be written:-

θV⋅Ix′; θV⋅P; and θ22V⋅Ix′ respectively

where Ix′ is the moment of inertia of the water-plane about Ox′, and P the product of inertia about Ox', Oy'. If the principal axes of inertia of the water-plane Ox, Oy make an angle ¢ with Ox', Oy', and if, from B as origin, axes Bx, By, Bz are drawn parallel to Ox, Oy, Oz, then the co-ordinates of B' are as follows:—

x= -BIB; cos ¢-BB; sin ¢=%-(P cos ¢>-l, ' sin ¢); y= BB, cos da-BIB; sin ¢=%(I, ,' cos 4:-l-P sin ¢); 0” 1

Z= B2B'=w'Iz .,

Also,

l, ,' = I, cos' ¢>+I, , sin' ¢;

P =(I, - I,) sin ¢ cos ¢; where Ix, Iy, are the principal moments of inertia of the water-plane. Hence

- x = −θV⋅Iy⋅sin φ;

- y = θV⋅Ix⋅cos φ;

- z = 12θ2V(Ixcos φ+Iysin2 φ).

Eliminating θ and φ, the locus of the centre of buoyancy for small inclinations of the ship becomes the elliptic paraboloid—

and the indicatrix is therefore similar and similarly situated to the

momental ellipse of the water-plane and the surface of buoyancy is

everywhere synclastic and concave to all points within it. The

quantities Iy/V and Ix/V are evidently equal to BMx and BMy (referring

to inclinations about Oy and Ox respectively); and the

indicatrix and momental ellipse become

x2 %f- +§ yTjI- =constant.

The angle φ that BB2 (the projection of BB′ on the plane of the indicatrix) makes with xO is given by

- tan φ= -%=-f. cot φ;

hence the direction is conjugate to that of the axis of rotation with respect to the indicatrix.

This is illustrated in fig. 25, where the ellipse shown is the indicatrix; OPx′ the axis of inclination, OQ the conjugate radius, and ORMy′ the perpendicular on the tangent. Draw QN parallel to OM to meet OP. The triangle OMQ is similar to BB1B2; and they can be made equal by giving a suitable value to the constant in the indicatrix equation. In that case QN is the projection on the plane of the figure of the normal to the surface at Bl, and the shortest distance between the normals at B and B1 is equal to ON = MQ =