Many, on opening the Encyclopedia of needlework will be disposed to exclaim as they read the heading of this first section: What is the use of describing all the old well-known stitches, when machines have so nearly superseded the slower process of hand-sewing? To this our reply is that, of all kinds of needlework, Plain Sewing needs to be most thoroughly learned, as being the foundation of all. Those who are able to employ others to work for them, should at least know how to distinguish good work from bad, and those who are in less fortunate circumstances, have to be taught how to work for themselves.

POSITION OF THE BODY AND HANDS.--Before describing different kinds of stitches, a word should be said as to the position of the body and hands when at work. Long experience has convinced me that no kind of needlework necessitates a stooping or cramped attitude. To obviate which, see that your chair and table suit each other in height, and that you so hold your work as hardly to need to bend your head at all. The practice of fastening the work to the knee, besides being ungraceful, is injurious to the health.

NEEDLES.--These should be of the best quality. To test a needle, try to break it; if it resist, and then break clean in two, the steel is good; if it bend without breaking, or break without any resistance, it is bad. Never use a bent needle, it makes ugly and irregular stitches, and see that the eye, whether round or egg-shaped, be well-drilled, that it may not fray or cut the thread. Long or half-long needles are the best for white work, long ones for dress-making, and longer ones still, with long eyes, for darning. A stock of each, from No 5 to 12, is advised. The needle should always be a little thicker than the thread, to make an easy passage for it through the stuff.

To keep needles from rusting, strew a little stone alum in the packets, and workers whose hands are apt to get damp, should have a small box of it handy, to powder their fingers with. Blackened needles can be made quite bright again by drawing them through an emery cushion.

SCISSORS.--Scissors are a very important accessory of the work-table, and two varieties are indispensable; a pair of large ones for cutting-out, with one point blunt and the other sharp, the latter to be always held downwards; and a pair of smaller ones with two sharp points. The handles should be large and round; if at all tight, they tire and disfigure the hand.

THIMBLE.--Steel thimbles are the best; bone are very liable to break, and silver ones are not deeply enough pitted, to hold the needle. A thimble should be light, with a rounded top and flat rim.

THE THREAD.--Except for tacking, your thread should never be more than from 40 to 50 c/m. long.[1] If the thread is in skeins, it does not matter which end you begin with, but if you use reeled cotton, thread your needle with the end that points to the reel, when you cut it; as the other end will split, and unravel, when twisted from left to right, which is generally done, to facilitate the process of threading. The cotton should always be cut, as it is weakened by breaking.

KNOTTING THE THREAD INTO THE NEEDLE (fig. 1).--When the thread becomes inconveniently short, and you do not want take a fresh one, it may be knotted into the needle, thus: bring it round the forefinger close to the needle, cross it on the inside next to the finger, hold the crossed threads fast, with the thumb draw the needle out through the loop thus formed, and tighten the loop round both ends.

MATERIALS.--For tacking, use Coton à coudre D.M.C qualité supérieure (black and gold stamp) Nos. 2 to 6.[A] For hand-sewing, Fil d'Alsace D.M.C Nos. 30 to 700,[A] and Fil à dentelle D.M.C, balls or reels, Nos. 25 to 100[A] will be found most useful. For machine-work: Câblé 6 fils pour machines D.M.C, Nos. 30 to 300,[A] black and white, or white and blue stamp. These can also be used for hand-work. Both these and the lace-thread (Fil à dentelle) on reels, are superfine in quality. The medium sizes are the most useful; but the only suitable ones for very fine and delicate fabrics are the Fil à dentelle D.M.C, and Fil d'Alsace, and the latter only is manufactured in the higher numbers.

All these threads are to be had, wound in balls, or on reels, the buyer may make his own choice; balls are apt to get tangled, but the cotton preserves its roundness better than when it is wound on reels. Linen is generally sewn with linen-thread, but Fil à dentelle and the Fil d'Alsace are very good substitutes.

POSITION OF THE HANDS (fig. 2).--The stuff, fastened to a cushion, must be held with the left hand, which should neither rest on the table, nor on the cushion, the needle must be held between the thumb and forefinger, of the right hand, and the middle finger, armed with the thimble, pushes the needle far enough through the stuff, for the other fingers to take hold of it and draw it out; the thread then comes to lie between the fourth and fifth fingers in the form of a loop, which must be tightened gradually to avoid its knotting.

POSITION OF THE HANDS WITHOUT CUSHION (fig. 3).--When the work cannot be fastened to a cushion it should be held between the forefinger and the thumb, and left hanging down, over the other fingers. If it need to be more firmly held, draw it between the fourth and fifth fingers, which will prevent it from getting puckered or dragged.

STITCHES.--Plain-Sewing comprises 4 varieties of stitches, (1) running, (2) back-stitching, (3) hemming and (4) top or over-sewing.

(1) RUNNING-STITCH (fig. 4).--This is the simplest and easiest of all. Pass the needle in and out of the material, at regular intervals, in a horizontal direction, taking up three or four threads at a time. If the stuff allow, several stitches may be taken on the needle at once, before the thread is drawn out. Running-stitch is used for plain seams, for joining light materials, for making gathers and for hems.

(2) BACK-STITCH (fig. 5).--Insert the needle, and draw it out six threads further on, carry your thread back, from left to right, and insert the needle three threads back from the point at which it was last drawn out, and bring it out six threads beyond. Stitching and back-stitching are better and more quickly done by machine than by hand.

STITCHING (fig. 6).--The production of a row of back-stitches, that exactly meet one another, constitutes what is called stitching. Only one stitch can be made at a time, and the needle must be put in, exactly at the point where it was drawn out to form the preceding back-stitch, and brought out as many threads further on as were covered by the last back-stitch. The beauty of stitching depends on the uniform length of the stitches, and the straightness of the line formed, to ensure which it is necessary to count the threads for each stitch, and to draw a thread to mark the line. If you have to stitch in a slanting line across the stuff, or the stuff be such as to render the drawing of a thread impossible, a coloured tacking thread should be run in first, to as a guide.

STITCHED HEM (fig. 7).--Make a double turning, as for a hem, draw a thread two or three threads above the edge of the first turning, and do your stitching through all three layers of stuff; the right side will be that on which you form your stitches.

(3) HEMMING-STITCH (fig. 8).--To make a good hem, your stuff must be cut in the line of the thread. Highly dressed stuffs, such as linen and calico; should be rubbed in the hand, to soften them, before the hem is laid. Your first turning should not be more than 2 m/m. wide; turn down the whole length of your hem, and then make the second turning of the same width, so that the raw edge is enclosed between two layers of stuff.

Narrow hems do not need to be tacked, but wide ones, where the first turning should only be just wide enough to prevent the edge from fraying, ought always to be. In hemming you insert the needle and thread directed in a slanting position towards you, just below the edge of the hem, and push it out two threads above, and so on to the end, setting the stitches, two or three threads apart, in a continuous straight line. To ensure the hem being straight, a thread may be drawn to mark the line for the second turning, but it is not a good plan, especially in shirt-making, as the edge of the stuff, too apt in any case, to cut and fray, is, thereby, still further weakened. Hems in woollen materials, which will not take a bend, can only be laid and tacked, bit by bit. In making, what are called rolled hems, the needle must be slipped in, so as only to pierce the first turning, in order that the stitches may not be visible on the outside.

FLAT SEAM (fig. 9).--Lay your two edges, whether straight or slanting, exactly even, tack them together with stitches 2 c/m. long, distant 1 to 2 c/m. from the edge, and then back-stitch them by machine or by hand, following the tacking-thread. Cut off half the inner edge, turn the outer one in, as for a hem and sew it down with hemming-stitches.

Smooth the seam underneath with the forefinger as you go, to make it lie quite flat. Beginners should flatten down the seam with their thimbles, or with the handle of the scissors, before they begin to hem, as the outer and wider edge is very apt to get pushed up and bulge over, in the sewing, which hides the stitches.

ROUNDED SEAM.--Back-stitch your two edges together, as above directed, then cut off the inner edge to a width of four threads, and roll the outer one in, with the left thumb, till the raw edge is quite hidden, hemming as you roll. This kind of seam, on the wrong side, looks like a fine cord, laid on, and is used in making the finer qualities of underclothing.

FASTENING THREADS OFF, AND ON (fig. 10).--Knots should be avoided in white work. To fasten on, in hemming, turn the needle backwards with the point up, take one stitch, and stroke and work the end of the thread in, underneath the turning. To fasten on, in back-stitching or running, make one stitch with the new thread, then take both ends and lay them down together to the left, and work over them, so that they wind in, and out of the next few stitches.

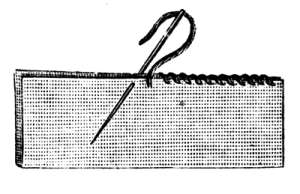

(4) TOP OR OVER-SEWING STITCH (fig. 11).--This stitch is used for joining selvedges together. To keep the two pieces even, it is better, either to tack or pin them together first. Insert the needle, from right to left, under the first thread of the selvedge, and through both edges, and sew from right to left, setting your stitches not more than three threads apart. The thread must not be drawn too tightly, so that when the seam is finished and flattened with the thimble, the selvedges may lie, side by side.

ANOTHER KIND OF SEWING-STITCH (fig. 12)--For dress-seams and patching; sew left to right, tacking or pinning the edges together first, and holding them tightly with the thumb and finger, to keep perfectly even.

ANTIQUE OR OLD-GERMAN SEAM (figs. 13 and 14).--Tack or pin the selvedges together as above, then, pointing your needle upwards from below, insert it, two threads from the selvedge, first on the wrong side, then on the right, first through one selvedge, then through the other, setting the stitches two threads apart. In this manner, the thread crosses itself, between the two selvedges, and a perfectly flat seam is produced. Seams of this kind occur in old embroidered linen articles, where the stuff was too narrow to allow for any other. A similar stitch, fig. 14, only slanting, instead of quite straight, as in fig. 13, is used in making sheets.

-

Fig. 13. Antique or old-german seam.

-

Fig. 14. Antique or old german seam.

FRENCH DOUBLE SEAM (fig. 15).--For joining such stuffs as fray, use the so-called French-seam.

Run your two pieces of stuff together, the wrong sides touching, and the edges perfectly even, then turn them round just at the seam, so that the right sides come together inside, and the two raw edges are enclosed between, and run them together again. See that no threads are visible on the outside. This seam is used chiefly in dress-making, for joining slight materials together which cannot be kept from fraying by any other means.

HEMMED DOUBLE SEAM (figs. 16 and 17).--Turn in the two raw edges, and lay them one upon the other, so that the one next the forefinger, lies slightly higher than the one next the thumb. Insert the needle, not upwards from below but first into the upper edge, and then, slightly slanting, into the lower one. This seam is used in dress-making, for fastening down linings. Fig. 17 shows another kind of double seam, where the two edges are laid together, turned in twice, and hemmed in the ordinary manner, with the sole difference, that the needle has to pass through a sixfold layer of stuff.

-

Fig. 16. Hemmed double-seam.

-

Fig. 17. Open hemmed double-seam.

GATHERING (fig. 18).--Gathers are made with running-stitches of perfectly equal length; take up and leave three or four threads, alternately, and instead of holding the stuff fast with your thumb, push it on to the needle as you go, and draw up your thread after every four or five stitches.

STROKING GATHERS (fig. 19).--When you have run in your gathering thread, draw it up tight, and make it fast round the finger of your left hand, and then stroke down the gathers with a strong needle, so that they lie evenly side by side, pushing each gather, in stroking it, under your left thumb, whilst you support the stuff at the back with your other fingers.

RUNNING IN A SECOND GATHERING THREAD (fig. 20).--This is to fix the gathers after they have been stroked, and should be run in 1 or 2 c/m. below the first thread, according to the kind of stuff, and the purpose it is intended for: take up five or six gathers at a time, and draw your two threads perfectly even, that the gathers may be straight to the line of the thread.

SEWING ON GATHERS (fig. 21).--To distribute the fulness equally, divide the gathered portion of material, and the band, or plain piece, on to which it is to be sewn, into equal parts, and pin the two together at corresponding distances, the gathered portion under the plain, and hem each gather to the band or plain piece, sloping the needle to make the thread slant, and slipping it through the upper threads only of the gathers.

WHIPPING (fig. 22).--Whipping is another form of gathering, used for fine materials. With the thumb and forefinger of the left hand, roll the edge over towards you, into a very tight thin roll, insert the needle on the inside of the roll next the thumb, and bring it out on the outside next the forefinger, at very regular distances, and draw up the thread slightly, from time to time, to form the gathers.

ORNAMENTAL HEM (fig. 23). For an ornamental hem, make a turning, 2 or 3 c/m. deep, and run in a thread, with small running-stitches up and down, as shown in fig. 23. By slightly drawing the thread, the straight edge will be made to look as if it were scalloped.

SEWING ON CORD (fig. 24).--For sewing on cord, use strong thread, either Fil d'Alsace D.M.C, Fil à dentelle D.M.C or Câblé 6 fils D.M.C No. 25, 30, 35 or 40.[A] Be careful not to stretch the cord, but to hold it in, as you sew it, as it invariably shrinks more than the stuff in the first washing. Fasten it with hemming stitches to the edge of the turning, taking care that it does not get twisted.

SEWING ON FLAPS (fig. 25).--These should be back-stitched on to the right side of the article they are to be affixed to, quite close to the edge, then folded over in half, and hemmed down on the wrong side. Like the cord, the flap must, in the process, be held in very firmly with the left hand. Though the back-stitching could be more quickly done by machine, hand-work is here preferable, as the holding in cannot be done by machine.

SEWING ON TAPE-LOOPS (figs. 26 and 27).--These, in the case of the coarser articles of household linen, are generally fastened to the corners. Lay the ends of your piece of tape, which should be from 15 to 17 c/m. long, side by side, turn in and hem them down, on three sides: the loop should be so folded as to form a three-cornered point, shewn in the illustration. Join the two edges of the tape together in the middle with a few cross-stitches, and stitch the edge of the hem of the article to the loop, on the right side.

Fig. 27 shows how to sew on a loop in the middle of an article, the two ends separately, one on one side, the other on the other.

-

Fig. 26. Sewing on tape-loops to the corner.

-

Fig. 27. Sewing on tape-loops in the middle of the article.

STRINGS AND LOOPS FOR FINE UNDER-LINEN (fig. 28).--Sew these on, likewise, on the wrong side of the article, hemming down the ends, and fastening them on the right side, with two rows of stitching crossing each other, and a third row along the edge.

BUTTON-HOLES IN LINEN (fig. 29).--Cut your hole perfectly straight, and of exactly, the diameter of the button, having previously marked out the place for it, with two rows of running-stitches, two or three threads apart. Put in your needle at the back of the slit, and take up about three threads, bring the working thread round, from right to left under the point of the needle, and draw the needle out through the loop, so that the little knot comes at the edge of the slit, and so on to the end, working from the lower left-hand corner to the right. Then make a bar of button-hole stitching across each end, the knotted edge towards the slit.

BUTTON HOLES IN DRESS MATERIALS (fig. 30).--Mark out and cut them as above described; if however, the material be liable to fray, wet the slit as soon as you have cut it, with liquid gum, and lay a strand of strong thread along the edge to make your stitches over; one end of dress button-holes must be round, the stitches diverging like rays from the centre, and when you have worked the second side, thread the needle with the loose strand, and pull it slightly, to straighten the edges; then fasten off, and close the button-hole with a straight bar of stitches across the other end, as in fig. 29.

SEWING ON BUTTONS (figs. 31 and 32).--To sew linen, or webbed buttons on to underclothing, fasten in your thread with a stitch or two, at the place where the button is to be; bring the needle out through the middle of the button, and make eight stitches, diverging from the centre like a star, and if you like, encircle them by a row of stitching, as in fig. 32. This done, bring the needle out between the stuff and the button, and twist the cotton six or seven times round it, then push the needle through to the wrong side, and fasten off.

-

Fig. 31. Sewing on linen buttons.

-

Fig. 32. Sewing on webbed buttons.

BINDING SLITS (figs. 33, 34, 35, 36).--Nothing is more apt to tear than a slit whether it be hemmed or merely bound. To prevent this, make a semicircle of button-hole stitches at the bottom of the slit, and above that, to connect the two sides, a bridge of several threads, covered with button-hole stitches.

In fig. 33, we show a hemmed slit, and in figs. 34 and 35, are two slits backed the one with a narrow, the other, with a broad piece of the material, cut on the cross.

In under-linen, it often so happens that two selvedges meet at the slit, which renders binding unnecessary; in that case take a small square of stuff, turn in the raw edges, top-sew it into the slit on two sides, turn in the other two, fold over on the bias, and hem them down over the top-sewing, as shewn in fig. 36. Such little squares of material, inserted into a slit or seam, to prevent its tearing, are called gussets.

-

Fig. 33. Binding slits with hem.

-

Fig. 34. Binding slits with piece on cross.

-

Fig. 35. Binding slits with broad band.

-

Fig. 36. Strengthening slits with gusset.

SEWING ON PIPING (fig. 37). Piping is a border, consisting of a cord or bobbin, folded into a stripe of material, cut on the cross, and affixed to the edge of an article to give it more strength and finish. It is a good substitute for a hem or binding on a bias edge, which by means of the cord, can be held in, and prevented from stretching. Cut your stripes diagonally, across the web of the stuff, and very even; run them together, lay the cord or bobbin along the stripe, on the wrong side, 5 m/m. from the edge, fold the edge over, and tack the cord lightly in. Then lay it on the raw edge of the article, with the cord towards you, and with all the raw edges turned away from you. Back-stitch the piping to the edge, keeping close to the cord. Then turn the article round, fold in the raw outside edge over the others, and hem it down like an ordinary hem.

FIXING WHALE-BONES (fig. 38).--Before slipping the whale-bone into its case or fold of stuff, pierce holes in it, top and bottom, with a red hot stiletto. Through these holes, make your stitches, diverging like rays or crossing each other as shown in fig. 38.

HERRING-BONING (fig. 39).--This stitch is chiefly used for seams in flannel, and for overcasting dress-seams, and takes the place of hemming, for fastening down the raw edges of a seam that has been run or stitched, without turning them in. Herring-boning is done from left to right, and forms two rows of stitches. Insert the needle from right to left, and make a stitch first above, and then below the edge, the threads crossing each other diagonally, as shewn in fig. 39.

FOOTNOTES:

[1] Our readers should be provided with a French metre, with the English yard marked on the back for purposes of comparison.

[A] See at the end of the concluding chapter, the table of numbers and sizes and the list of colours of the D.M.C threads and cottons.