of the same substance under similar conditions. The specific heat of a substance is sometimes defined as the thermal capacity of unit mass, but more often as the ratio of the thermal capacity of unit mass of the substance to that of unit mass of water at some standard temperature. The two definitions are identical, provided that the thermal capacity of unit mass of water, at a standard temperature, is taken as the unit of heat. But the specific heat of water is often stated in terms of other units. In any case it is necessary to specify the temperature, and sometimes also the pressure, since the specific heat of a substance generally depends to some extent on the external conditions. The methods of measurement, founded on rise of temperature, may be classed as thermometric methods, since they depend on the observation of change of temperature with a thermometer. The most familiar of these are the method of mixture and the method of cooling.

§ 2. The Method of Mixture consists in imparting the quantity of heat to be measured to a known mass of water, or some other standard substance, contained in a vessel or calorimeter of known thermal capacity, and in observing the rise of temperature produced, from which data the quantity of heat may be found as explained in all elementary text-books. This method is the most generally convenient and most readily applicable of calorimetric methods, but it is not always the most accurate, for various reasons. Some heat is generally lost in transferring the heated body to the calorimeter; this loss may be minimized by performing the transference rapidly, but it cannot be accurately calculated or eliminated. Some heat is lost when the calorimeter is raised above the temperature of its enclosure, and before the final temperature is reached. This can be roughly estimated by observing the rate of change of temperature before and after the experiment, and assuming that the loss of heat is directly proportional to the duration of the experiment and to the average excess of temperature. It can be minimized by making the mixing as rapid as possible, and by using a large calorimeter, so that the excess of temperature is always small. The latter method was generally adopted by J. P. Joule, but the rise of temperature is then difficult to measure with accuracy, since it is necessarily reduced in nearly the same proportion as the correction. There is, however, the advantage that the correction is rendered much less uncertain by this procedure, since the assumption that the loss of heat is proportional to the temperature-excess is only true for small differences of temperature. Rumford proposed to eliminate this correction by starting with the initial temperature of the calorimeter as much below that of its enclosure as the final temperature was expected to be above the same limit. This method has been very generally recommended, but it is really bad, because, although it diminishes the absolute magnitude of the correction, it greatly increases the uncertainty of it and therefore the probable error of the result. The coefficient of heating of a calorimeter when it is below the temperature of its surroundings is seldom, if ever, the same as the coefficient of cooling at the higher temperature, since the convection currents, which do most of the heating or cooling, are rarely symmetrical in the two cases, and moreover, the duration of the two stages is seldom the same. In any case, it is desirable to diminish the loss of heat as much as possible by polishing the exterior of the calorimeter to diminish radiation, and by suspending it by non-conducting supports, inside a polished case, to protect it from draughts. It is also very important to keep the surrounding conditions as constant as possible throughout the experiment. This may be secured by using a large water-bath to surround the apparatus, but in experiments of long duration it is necessary to use an accurate temperature regulator. The method of lagging the calorimeter with cotton-wool or other non-conductors, which is often recommended, diminishes the loss of heat considerably, but renders it very uncertain and variable, and should never be used in work of precision. The bad conductors take so long to reach a steady state that the rate of loss of heat at any moment depends on the past history more than on the temperature of the calorimeter at the moment. A more serious objection to the use of lagging of this kind is the danger of its absorbing moisture. The least trace of damp in the lagging, or of moisture condensed on the surface of the calorimeter, may produce serious loss of heat by evaporation. This is another objection to Rumford’s method of cooling the calorimeter below the surrounding temperature before starting. Among minor difficulties of the method may be mentioned the uncertainty of the thermal capacity of the calorimeter and stirrer, and of the immersed portion of the thermometer. This is generally calculated by assuming values for the specific heats of the materials obtained by experiment between 100° C. and 20° C. Since the specific heats of most metals increase rapidly with rise of temperature, the values so obtained are generally too high. It is best to make this correction as small as possible by using a large calorimeter, so that the mass of water is large in proportion to that of metal. Analogous difficulties arise in the application of other calorimetric methods. The accuracy of the work in each case depends principally on the skill and ingenuity of the experimentalist in devising methods of eliminating the various sources of error. The form of apparatus usually adopted for the method of mixtures is that of Regnault with slight modifications, and figures and descriptions are given in all the text-books. Among special methods which have been subsequently developed there are two which deserve mention as differing in principle from the common type. These are (1) the constant temperature method, (2) the continuous flow method.

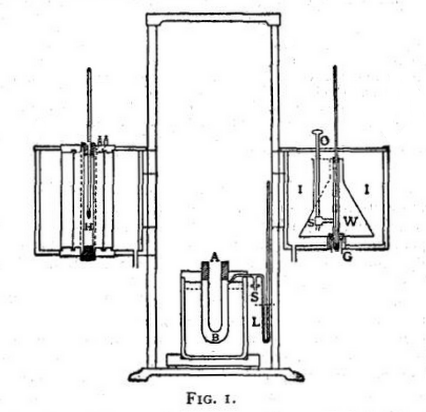

The constant temperature method of mixtures was proposed by N. Hesehus (Jour. Phys., 1888, vii. p. 489). Cold water at a known temperature is added to the calorimeter, immediately after dropping in the heated substance, at such a rate as to keep the temperature of the calorimeter constant, thus eliminating the corrections for the water equivalent of the calorimeter and the external loss of heat. The calorimeter is surrounded by an air-jacket connected to a petroleum gauge which indicates any small change of temperature in the calorimeter, and enables the manipulator to adjust the supply of cold water to compensate it. The apparatus as arranged by F. A. Waterman is shown in fig. 1 (Physical Review, 1896, iv. p. 161).

|

A is the calorimetric tube, B the air-jacket and L the gauge. H is an electric heater for raising the body to a suitable temperature, which can swing into place directly over the calorimeter. W is a conical can containing water cooled by ice I nearly to 0°, which is swung over the calorimeter as soon as the hot body has been introduced and the heater removed. The cold water flow is regulated by a tap S with a long handle O, and its temperature is taken by a delicate thermometer with its bulb at G. The method is interesting, but the manipulations and observations involved are more troublesome than with the ordinary type of calorimeter, and it may be doubted whether any advantage is gained in accuracy.

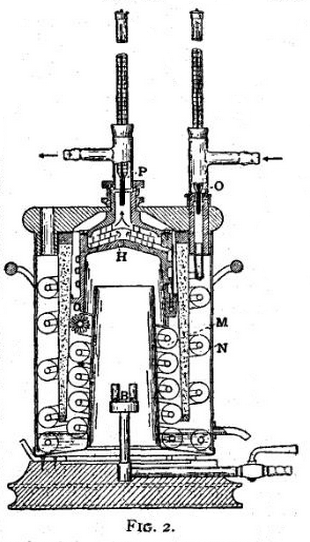

The continuous flow method is specially applicable to the important case of calorific value of gaseous fuel, where a large quantity of heat is continuously generated at a nearly uniform rate by combustion. Fig. 2 illustrates a recent type of gas calorimeter devised by C. V. Boys (Proc. R.S., 1906, A. 77, p. 122). The heated products of combustion from the burner B impinge on a metal box H, through which water is circulating, and then pass downwards and outwards through a spiral cooler which reduces them practically to the atmospheric temperature. A steady

stream of water enters the apparatus by the inflow thermometer O,