employed, and the coils are either wound by hand directly on to the armature core, or are shaped on formers prior to being inserted in the armature slots. Hand-winding is now only employed in very small bipolar machines, the process being expensive and accompanied by the disadvantage that if one section requires to be repaired, the whole armature usually has to be dismantled and re-wound. Former-wound coils are, on the other hand, economical in labour, perfectly symmetrical and interchangeable, and can be thoroughly insulated before they are placed in the slots. The shapers employed in the forming process are very various, but are usually arranged to give to the finished coil a lozenge shape, the two straight active sides which fit into the straight slots being joined by V-shaped ends; at each apex of the coil the wire is given a twist, so that the two sides fall into different levels, an upper and a lower, corresponding to the two layers which the coil-sides form on the finished armature. Rectangular wire of comparatively small section may be similarly treated, and if only one loop is required per section, wide and thin strip can be bent into a complete loop, so that the only soldered joints are those at the commutator end where the loops are interconnected. But finally with massive rectangular conductors, the transition must be made to bar-winding, in which each bar is a half-loop, insulated by being taped after it has been bent to the required shape; the separate bars are arranged on the armature in two layers, and their ends are soldered together subsequently to form loops. As a general rule, whether bars or former-wound coils are employed, the armature is barrel-wound, i.e. the end-connexions project outwards from the slots with but little change of level, so that they form a cylindrical mass supported on projections from the end-plates of the core (fig. 19); but, in certain cases, the end-connexions are bent downwards at right angles to the shaft, and they may then consist of separate strips of copper bent to a so-called butterfly or evolute shape.

After the coils or loops have been assembled in the slots on the armature core, and the commutator has been fixed in place on the shaft, the soldering of the ends of the coils proceeds, by which at once the union of the end of one coil with the beginning of the next, and also their connexion to the commutator sectors, is effected, and in this lies the essential part of armature winding.

|

| Lap-loops Fig. 20. |

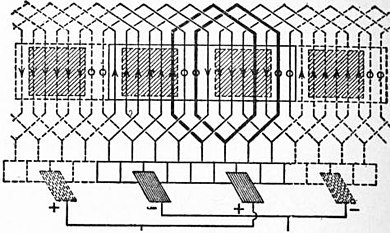

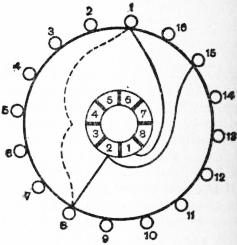

The development of the modern drum armature, with its numerous coils connected in orderly sequence into a symmetrical winding, as contrasted with the earlier Siemens armatures, was initiated by F. von Hefner Alteneck (1871), and the laws governing the interconnexion of the coils have now been elaborated into a definite system of Lap-winding.winding formulae. Whatever the number of wires or bars in each side of a coil, i.e. whether it consist of a single loop or of many turns, the final connexions of its free ends are not thereby affected, and it may be mentally replaced by a single loop with two active inducing sides. The coil-sides in their final position are thus to be regarded as separate primary elements, even in number, and distributed uniformly round the armature periphery or divided into small, equally spaced groups by being located within the slots of a toothed armature. Attention must then be directed simply to the span of the back connexion between the elements at the end of the armature further from the commutator, and to the span of the front connexion by which the last turn of a coil is finally connected to the first turn of the next in sequence, precisely as if each coil of many turns were reduced to a single loop. In order to avoid direct differential action, the span of the back connexion which fixes the width of the coil must exceed the width of the pole-face, and should not be far different from the pole-pitch; it is usually a little less than the pole-pitch. Taking any one element as No. 1 in fig. 20, where for simplicity a smooth-core bipolar armature is shown, the number of winding-spaces, each to be occupied by an element, which must be counted off in order to find the position of the next element in series, is called the “pitch” of the end-connexion, front or back, as the case may be. Thus the back pitch of the winding as marked by the dotted line in fig. 20 is 7, the second side of the first loop being the element numbered 1 + 7=8. In forming the front end-connexion which completes the loop and joins it to the next in succession, two possible cases present themselves. By the first, or “lap-winding,” the front end-connexion is brought backwards, and passing on its way to a junction with a commutator sector is led to a third element lying within the two sides of the first loop, i.e. the second loop starts with the element, No. 3, lying next but one to the starting-point of the first loop. The winding therefore returns backwards on itself to form each front end, but as a whole it works continually forwards round the armature, until it finally “re-enters,” after every element has been traversed. The development of the completed winding on a flat surface shows that it takes the form of a number of partially overlapping loops, whence its name originates. The firm-line portion of fig. 21 gives the development of an armature similar to that of fig. 18 when cut through at the point marked X and opened out; two of the overlapping loops are marked thereon in heavy lines. The multipolar lap-wound armature is obtained by simply repeating the bipolar winding p times, as indicated by the dotted additions of fig. 21 which convert it from a two-pole to a four-pole machine. The characteristic feature of the lap-wound armature is that there are as many parallel paths from brush to brush, and as many points at which the current must be collected, as there are poles. As the bipolar closed-coil continuous-current armature has been shown to consist in reality of two circuits in parallel, each giving the same E.M.F. and carrying half the total current, so the multipolar lap-wound drum consists of p pairs of parallel paths, each giving the same E.M.F. and carrying 1/2p of the total current. Thus in equation 1.b we have q=2p, and the special form which the E.M.F. equation of the lap-wound armature takes is Ea=Za (N / 60)τ × 10–8 volts. All the brushes which are of the same sign must be connected together in order to collect the total armature current. The several brush-sets of the multipolar lap-wound machine may again be reduced to two by “cross-connexion” of sectors situated 360°/p apart, but this is seldom done, since the commutator must then be lengthened p times in order to obtain the necessary brush contact-surface for the collection of the entire current.

Fig. 21. |

Wave-loops Fig. 22. |

Fig. 23. |