the side of the outer cylinder below this, there is a wide and rimmed

aperture, to which a gas regulator of special construction is fixed.

|

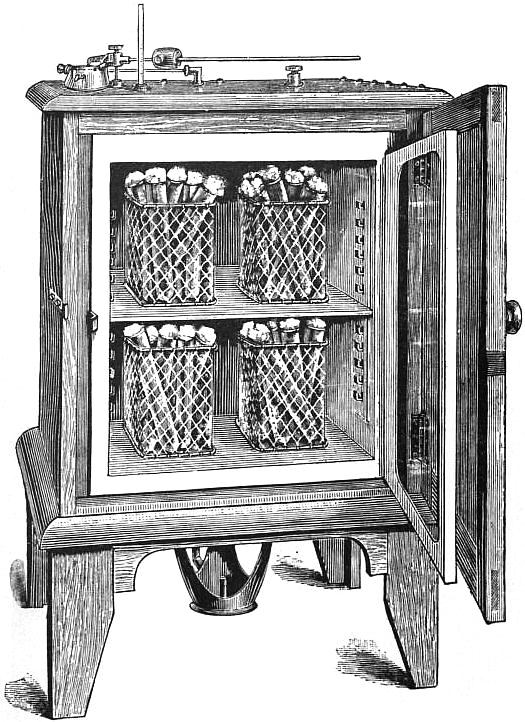

| Fig. 8.—D’Arsonval Incubator. |

This regulator was designed by Théophile Schloesing, and consists of a brass box, supplied with a rim (L) which fits on to the corresponding rim (L′) on the aperture of the incubator. Stretching across the orifice thus connecting the brass box of the regulator with the water-tank of the incubator is a thin india-rubber diaphragm (D). At its outer end a perforated cap (R) screws on to the brass box. Through the perforation the inlet gas tube passes (I); the outlet gas tube (O) leaves the brass box below and passes direct to the gas burners. The inlet gas tube is fitted at its inner end with a sliding flanged collar (F), which is kept pressed against the rubber diaphragm by a spiral spring. Just behind the collar the inlet tube is perforated by a small hole, so that the gas supply is never wholly cut off, even though the rubber diaphragm completely occludes the inner aperture of the pipe.

The mode of working of the regulator is as follows: when the water tank of the incubator is filled with distilled or rain water at the temperature required, it presses upon the india-rubber diaphragm with a certain degree of pressure. By screwing the inlet pipe in or out, as required, it can be so adjusted that the diaphragm does not occlude its inner aperture, and consequently the full volume of gas can pass through to the burners below. The temperature of the water in the water-tank therefore begins to rise, and in consequence the volume of the water to increase. This results in the water rising up into the tube (T), and therefore the dynamical pressure which is exercised by the water upon every part of the two cylinders of the incubator and consequently also upon the india-rubber diaphragm of the regulator is increased. As this pressure increases, the diaphragm becomes bulged outwardly and reduces the volume of gas passing through the aperture of the inlet pipe. At a certain point, of course, the diaphragm completely occludes the aperture, and the gas supply is wholly cut off, except for the very small hole, forming a by-pass, in the pipe, behind the collar. This hole is just sufficiently big to allow the minimum amount of gas requisite to keep the flames burning to pass through. The temperature will, therefore, begin to fall, the volume of water to decrease with its resulting descent from the glass tube (T) and consequent decrease in the dynamical pressure of the water upon the diaphragm. The latter therefore retracts away from the aperture of the inlet tube, and more gas consequently passes through; the flames again increase in size and the temperature rises once more. And as soon as the volume of water, owing to the rising temperature, has increased to the extent correlated with the temperature at which the apparatus has been set to work, it will have risen once more in the tube (T), and the gas will be again cut off. The three burners are placed upon a support that can be moved vertically up or down along one of the legs of the incubator. The flames are protected from draughts by mica chimneys. Ventilation is provided by an adjustable valve (V′) in the cylindrical termination of the incubator at its lower end, and by tubular orifices, also fitted with valves (V) in the lid above.

The incubator is very reliable and may be worked within very narrow limits of variation, provided that the gas-supply be regulated by a gas-pressure regulator, that the height of the water in the tube (T) is maintained by daily additions of a few drops of distilled water, and that the incubator itself be protected from draughts.

Another form of d’Arsonval incubator has a glass door in the side of it and a slightly modified form of the heat regulator.

Other cylindrical forms of incubators are made by Lequeux of Paris. In one of these the heat regulator is a bimetallic thermostat, the movements of which are enlarged by a simple series of levers, so that a valve can be automatically adjusted to allow more or less heat from the flame to pass through the heating flue.

In another form there is a movable interior, and an arrangement for keeping the air in the incubation chamber saturated. It is governed by a bimetallic thermostat of the Roux type.

In Dr Hüppe’s improved form of his incubator, which is approximately square in form, the double-walled water tank is completely surrounded externally by an air chamber, which is heated by the passage through it of the products of combustion of the two flames. The heated gases escape through an adjustable aperture at the top. In the earlier form the water tank was traversed by a number of hot-air flues, and there was consequently no external hot-air chamber. There is an arrangement of tubes for ventilation, which allow fresh air to enter the lower part of the incubation chamber and to leave it at the top. The incoming air is warmed before it enters. The walls are made of lead-coated steel, and externally the incubator is covered with linoleum. In the more expensive forms the inner chamber is of copper. The temperature may be controlled by any of the simpler mercury thermostats described below.

Dr Babes’ incubator is somewhat similar, but the water tank is not surrounded by a hot-air chamber. Instead it is traversed by a number of vertical flues through which the heated gases from the flames pass. Ventilation is provided for and there is an apparatus for controlling the humidity of the air in the incubation chamber. As in Hüppe’s incubator, the bottom is conical in form. The walls of the incubator are of lead-coated steel, and externally they are covered with linoleum; there are two doors, an inner one of glass and an outer one of metal. The temperature may be controlled as in Hüppe’s incubator.

Hearson has designed several forms of bacteriological (biological) incubators, made by Chas. Hearson & Co., Ltd. Some are heated by a petroleum lamp and others by a gas flame. In the form heated by a lamp, for which, however, gas can be substituted, the incubation chamber is surrounded by a water tank (fig. 9, A) and the lowest part of this is traversed by an in-going (L) and an out-going flue. The mode of regulation of the temperature is by means of a thermostat which operates the movements of a cap (F) over the main flue (V), and it is identical in its chief features with the method employed in the chicken incubator. The thermostat (S) is situated in the upper part of the incubation chamber.

|

| Fig. 9.—Hearson’s Bacteriological Incubator. (Heated by a petroleum lamp.) |

In the other form (fig. 10) for which gas is used exclusively, there are no flues traversing the water tank. This latter is heated from its conical floor by a burner beneath the incubator. The heat regulation is controlled by a thermostat of the same nature as in the form of incubator just described, but instead of operating by lowering or raising a cap over a main flue, so as to direct the heated gases either through the water tank if the temperature is falling, or through the main flue directly to the exterior if it is rising, it actuates a gas-governor, so that the flame itself is increased or diminished in size according to the needs of the incubator. The gas-governor (fig. 11) is fixed to the roof of the incubator. The horizontal arm (D) is the same that raises the cap (fig. 9, F) over the flue in the other form of incubator, but in this case it simply acts as the bearer of the sliding weight. Beyond its fulcrum (fig. 11, G) it is continued into a detent-like spur (B) which pushes down upon a button attached to a rubber diaphragm, when the thermostat within the incubator is expanded by a rise in temperature. The button thus forced down, more or less completely closes the inlet gas aperture, and so reduces or cuts off the gas supply to the flame. There is a by-pass to prevent the flame from going out completely, and the size of this can be adjusted by the screw (S). Hearson’s incubators have the reputation of very accurate performance and practically need no attention for months, or even years.

|

| Fig. 10.—Hearson’s Bacteriological Incubator (heated by a gas flame). |

|

| Fig. 11.—Gas-governor. |

Schribaux’s incubator is a hot-air form. Its walls are of metal,