asbestos fabric on both sides. Its advantage over the lubricated disk clutch was that its operation was not affected by changes in atmospheric temperature, as was that of the latter. There were no important developments in the design of gearsets or transmissions;

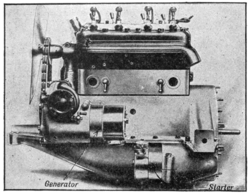

Fig. 7. Fiat (Italian) engine, showing method of mounting electric generator and starter.

nearly all manufacturers of passenger cars used the selective sliding pinion type, and this type was also on most commercial vehicles.

Chain drive was almost entirely discarded, except on trucks in continental Europe, and shaft and bevel-gear drive became the standard for passenger motor-cars throughout the world. But two important improvements were made in this drive. One was the substitution of spiral bevel for straight bevel gears, to secure quiet operation, and the other the partial substitution of disk universal joints for the metallic type, the former requiring no lubrication. The spiral bevel gear (fig. 9) was made possible by a gear-cutting machine developed by the Gleason Works of Rochester, N.Y., and the fabric disk universal joint (fig. 10) by a fabric structure originated by Ed. J. Hardy & Co. of Coventry, England. Practice in regard to final drives for motor lorries remained in a chaotic state in 1920. In continental Europe the chain drive was still predominant, while in

Fig. 8. Sectional view of dry-disk clutch.

Great Britain and the United States the worm drive was in most extensive use. Of the lorry models manufactured in Great Britain in 1920 roughly 50% had worm drive, 25 % chain drive and 25% the double-reduction drive, or drive by one pair of bevel and one pair of spur gears enclosed at the middle of the axle. In the United States the most popular drive next to the worm was the internal gear drive, in which there was a first reduction by bevel gears at the middle of the axle and a second by internal gears at the driving wheels.

In connexion with lorry axles mention should be made of the development and use, mainly in the United States, of so-called nonstalling differential gears. A vehicle fitted with this type of differential would not lose all traction when one driving wheel gets on slippery ground; on the other hand, in turning corners the drive was

Fig. 9. Central part of a rear axle with inspection cover removed, showing spiral bevel gear.

entirely through the inner wheel. A type of body suspension spring that gained much in popularity between 1910 and 1920 was the cantilever type first used by F. W. Lanchester in England. The most extensively used type in 1920 was the half-elliptic. Many attempts were made to solve the problem of furnishing the springs with effective means of lubrication, to make them as supple as possible and to prevent squeaking, and in England the practice of enclosing the springs in leather gaiters gained some ground. In the connexion between the rear axle and the frame provision must be made for taking up the driving thrust necessary to overcome the air resistance and the resistance encountered by the front wheels, as well as the reaction to the rear-wheel driving torque, which tends to turn the axle housing in the direction opposite to that in which the wheels are turning. In one construction, known as the Hotchkiss drive, both the drive and the torque reaction were taken up on the body springs, which were securely clipped to the axle housing and directly pinned to the frame at their forward end. This construction became very popular in the United States for both passenger cars and lorries, and was successfully used even on the heavy military lorries. European designers, on the other hand, favoured the torque-tube construction for passenger cars. In this the propeller shaft was surrounded by a torque tube which was rigidly secured to the housing at the centre of the rear axle, and at its forward end had either a forked or a spherical connexion to a cross member of the frame or the rear end of the transmission case. In the United States one manufacturer after another

Fig. 10. Thermoid-Hardy fabric universal joint.

adopted the plan of mounting the steering post on the left side, realizing that in a country where the "right-hand" rule of the road obtains the balance of advantages rests with the left-hand drive. Left-hand steering fits in well with brake and gear-shift levers mounted in the centre of the car, as the driver can use his right hand to operate them. In Great Britain, where the rule of the road is to "keep to the left," right-hand steering has the same advantages as left-hand steering in other countries.

Great improvements were made in hoods and wind-screens. Hoods of 1920 cars could readily be raised and lowered by a single person. The forward end of the hood usually joined up to the wind-screen supports, and by means of easily folded side curtains with transparent celluloid inserts, an open car could quickly be enclosed. Wind-screens were usually in two parts and permitted various adjustments. By setting the lower edge of the upper part slightly