Popular Science Monthly/Volume 36/December 1889/Glass-Making III

| GLASS-MAKING. |

By C. HANFORD HENDERSON,

PROFESSOR OF PHYSICS AND CHEMISTRY IN THE PHILADELPHIA MANUAL TRAINING SCHOOL.

III.—THE EVOLUTION OF A GLASS BOTTLE.

TO a little sand, a little alkali, and a little limestone, add considerable heat and a still greater amount of skill, might be taken as a brief recipe for the manufacture of a glass bottle.

But to know in just what proportions to mix these several ingredients, how to produce and manage the requisite heat, and particularly how to cultivate that most essential part of the whole process, the manual dexterity which gives value to these other factors, are matters less briefly disposed of. Their consideration has made the evolution of a glass bottle a history covering several thousand years. The importance of this modest process will appear, if one is not already persuaded of it, when one recalls for an instant the multitudinous uses to which bottles are now put. It is difficult to fancy the confusion which would result were so simple an article of commerce suddenly withdrawn from the world of fact, and society called upon to manage without its service. Great would be the consternation of a host of manufacturers, and loud the outcry of a larger host of consumers.

The earlier man, it is to be remembered, had his herds always with him, his spring of water near his tent-door. He knew no tonic save the air of the desert, and few other beverages than the wine which was stored in sacks of goat's skin. To him bottles and their contents were matters of little moment. It is true that, in the storage of the one liquid which he preserved in this way, he did have to be careful not to put new wine into old bottles, but the proverb was easily recalled, and its precaution not difficult to carry out. He contented himself with his sack of skin, and found, in the projection which had once been the leg or neck of the animal, a mouth to his bottle sufficiently convenient to serve his purpose.

It was from receptacles such as this that the tired heroes of the Iliad regaled themselves, and the aged Noah partook too generously.

Even now this primitive bottle is largely used for the transportation and storage of water by the people of western Asia, and the usage seems to possess enough inertia to carry it forward several centuries further. Invading Americans may find the bottle of skin still in vogue, when their restless westward-moving activity carries them across the Pacific.

The substitution of glass bottles was effected but slowly even among the more progressive of ancient peoples. In the use of glass, the idea of beauty and decoration long remained paramount to considerations of utility. It was an article of luxury rather than of necessity. Darwin observed with amazement that when the weather was warm and fair, the Fijians paraded their coats of furs and feathers with all the pomp and pride of the Parisian beau-monde, only to stand naked and shivering in times of storm. It seems to have been much the same thing among the ancients with respect to their glass bottles. It was ornament in place of use. They were quite willing to get along without them in the economy of every-day life, provided they could have a few rare vases and gold-mounted amphoræ in the early salons where Rameses gossiped about Egyptian politics, and Potiphar discoursed upon the mysteries of metempsychosis.

It must be confessed that, in the pursuit of this one idea, they were eminently successful. Their glass trinkets were beautiful, both in outline and in color, even if their bottles for real service were made of skin, and liable to rip and tear. The glass bric-à-brac of antiquity, its bottles and vases and jars, was not of large dimension, but it possessed a profusion of color which we have only of recent years been able to imitate.

With us moderns, however, life is much more complex, and the case is quite different. We are not insensible to ornamentation, but we are more keenly alive to comfort. In the absence of a king's taster, we are disposed to guard what we eat and drink. The majority agree with Charles Lamb, that poisoning is "a nasty death," and so we eschew the use of metals in contact with our foods, and much prefer glass. We want milk miles from where it is produced, and fruits and vegetables months after their harvest. We want medicines for health, balms for bruises, tonics for appetites, mineral waters for digestion, wines for strength, condensed products for our travel. We want to separate with acids and put together with glues. We want a host of other things which come in bottles. We even bottle our electricity if so unscientific an expression may be applied to the storage-battery. There is, in fact, scarcely a single department of life, either social or industrial, where some product is not needed which must be kept or carried in some form of glass bottle or jar. The manufacture of so useful an article is thus brought into relation with all of our many-sided activity. It forms a distinct and very important branch of the glass industry.

In America, the process of bottle-making is nowhere carried on more extensively or more successfully than in the neighborhood of Philadelphia. Much of the sand of southern New Jersey is sufficiently pure to make an excellent bottle-glass. Its adaptability for this purpose seems to have been appreciated by the early colonists, for the oldest glass-works in this country are those established in 1775 at Glassboro. They are still in operation, and are at the present day the most extensive of American bottle-works, employing as they do some six hundred persons in the conduct of their operations. It is a significant fact, showing the force of modern progress, that after existing for more than a century, the capacity of the "plant" was increased over fifty per cent during a recent period of three years. It is one of several establishments which have grown up in that neighborhood, and which have been attracted by the same cause, the abundance of a fair quality of sand. There is, moreover, something highly gregarious about modern industries. It frequently happens that many other localities offer quite as favorable conditions as the one selected; but the simple presence of a successful industry seems to turn men's thoughts in that direction, and lead them to undertake similar enterprises rather than to attempt the dangerous experiment of importing a new manufacture. To this principle of gregariousness, as well as to the wide wastes of sand, must the community of glass-workers in southern New Jersey be attributed. Like apparently begets like.

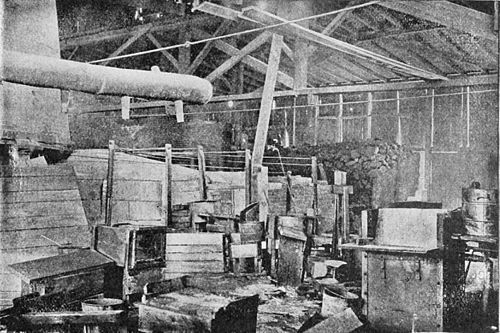

Fig. 1.—A Glass-Bottle Factory at Southern New Jersey.

There is little that is attractive about the exterior of such a bottle-factory. One finds it set down in the midst of a flat, monotonous country, and surrounded by indifferent wooden houses with bare, sandy door-yards which bespeak small appreciation of the element of beauty. That these houses are homes, and are for the most part owned by those who live in them, adds immensely to their interest, but it does not conceal the fact that life here is material and ugly. It is not a beautiful or an inspiring thing to blow bottles all day long, unless one does it remarkably well; but the industry remaining, the life in these towns might still be made much less bare than it is, could that gospel of happiness and culture which Mr. Walter Besant and others are preaching in the East End of London find here some good apostle who would make it the burden of a new evangel.

In the larger bottle-works there are generally several melting furnaces, but each is complete in itself, a unit from which a larger or smaller plant may be constructed, according to the requirements of the case. Each furnace is lodged in its own building. A certain symmetry is loaned to these low, rectangular wooden structures by the tall brick furnace-shaft which rises through the center of the roof, and by the numerous smaller chimneys scattered around the edge. The sides of the building are movable on pivots, and when open give the factory somewhat the appearance of the Japanese houses pictured by Mr. Morse.

Inside of the factory all is life and movement. But, amid the dirt and confusion which characterize such an interior, there are the order of active money-getting and the beauty of a long-practiced dexterity.

If one follow the crude materials from the time they enter the building until they finally emerge in the form of many-shaped bottles, he will begin his inspection at the mixing-room, where the questions of content and proportion are decided. Large wooden wheelbarrows come and go, stopping long enough only to have their weight taken, and to dump their thoroughly ground contents into one of the bins on the side of the room. Patient old men, with hoe and shovel, mechanically mix together the stuff for the "batch" This varies in its composition according to the sort of bottles that are to be made. Three grades of bottle glass are recognized. The ordinary green glass is obtained from a mixture of about thirty-eight parts of soda and twenty parts of marble-dust to every hundred parts of sand. The glass is essentially a lime-soda glass, not dissimilar to window glass in its composition. The sand used comes from the neighborhood, and contains a little iron. As no bleaching agents are employed, this gives the glass its characteristic light green color—the bottle-green of our colorists. The second grade, the amber glass, has about the same composition, only it is colored by the addition of a little ground coke, black-lead, or some other form of carbon, about eight ounces to every hundred pounds of sand. This makes a much less innocent-looking bottle than the sea-green tint of the first glass. The finest grade, the so-called flint glass, contains about the same ingredients as the ordinary bottle glass, but the materials used are purer, and some such bleaching agent as manganese dioxide, arsenious acid, or nitrate of soda is used to make the glass colorless. Blue bottles are occasionally wanted, and in that case a little peroxide of cobalt is added to the customary batch to give the required color.

To obtain the best results, it is essential that the grinding and mixing of the crude materials be carefully looked after. At Glassboro the mixing as well as the grinding will soon be done by machinery in one central mixing-room, and the batch conveyed to the different furnaces by means of endless belts. It is believed that this improvement will insure a better product as well as more economical working.

The batch having been prepared, the next step in the development of the bottle is to change this dull-white powder into clear, fluid glass. Such a metamorphosis is accomplished in the melting furnace, which forms very naturally the central feature in a bottle-factory. The gratifying increase in the capacity of the Glassboro works is largely if not entirely due to the introduction of improved furnaces invented by the chemist of the works, Mr. Andrew Ferrari. They are continuous tank furnaces heated by gas—that is to say, the melting is carried out in large fire-clay tanks, and proceeds without interruption. There are other tank furnaces in use in America, but these are probably the only works where the melting is carried out continuously. Neither the employment of a tank in place of separate crucibles, nor the substitution of a gaseous for a solid fuel, is in itself new; but the details of the Ferrari furnace are quite novel. In Europe, the regenerative system of Siemens has been employed with marked success in the manufacture of glass; but, unfortunately, the Siemens furnaces are expensive in their construction and require some degree of skill to insure their best working. The Ferrari furnace, on the other hand, is an inexpensive affair and is easily worked. The gas generator is the usual inclined or "step" grate employed by Siemens, but it is placed directly alongside of the furnace, thus obviating the transportation of the gas, and the consequent necessity of reheating it before combustion.

At one end of the building one sees an elevated platform on which are stacked large blocks of bituminous coal. About six tons are daily required for each furnace. From this platform a line of low, irregular brick-work extends to the central stack. It contains the gas generators, three to each furnace, and beyond them the melting tank, which communicates on the other side with what is known as the working part of the furnace, lying directly under the central stack. The coal is fed directly into the generators from the platform, and on the inclined grate is completely burned—that is to say, it unites with all the oxygen possible, forming carbonic-acid gas. The supply of air may be regulated by dampers, so that the generator yields more or less gas according to the requirements of the furnace. But the carbonic-acid gas thus produced would be of no value as fuel, for it is totally incombustible. Rising, however, through the mass of incandescent fuel above it, the gas is speedily reduced to the condition of carbonic oxide, that combustible gas whose blue flame plays over

Fig. 2.—An Interior View, showing the Brick-work which contains the Gas Generators and Melting Tank.

the surface of an anthracite fire just after fresh fuel has been thrown on. This mixes with the volatile hydrocarbons the coal-gas given off when fresh coal is introduced into the generator and the mixture passes at once to the chamber above the melting tank. The air necessary for the burning of these generator gases is first heated by passing through a number of chambers in the lower part of the furnace. It is mixed with the gases to be burned just before they reach the fire-clay bridge separating the gas generator from the melting tank. The main combustion takes place right at this bridge, and produces an intense heat in the melting chamber, for both the gas to be burned and the air to burn it are highly heated before they are allowed to combine. The effect is the same as would be produced on a small scale if one fed his stove with the hot air from a register. This arrangement removes in a simple and inexpensive way one of the chief objections to the use of gas in glass-making. The fuel is so exceedingly convenient that its use in the industry was proposed, and indeed attempted, years ago, but a sufficiently intense heat could not be thus obtained.

The furnaces are in continuous operation for ten months in the year. Every three hours during the entire twenty-four a charge of a ton and a half of the batch is added to the melting tank. In an atmosphere so intensely heated as this, it does not take very long for the crude materials to fuse and form a glass quite as liquid as water.

Picture for a moment the white-hot caldron in which this transformation of the opaque into the transparent takes place. It is an oblong tank, some eight by ten feet, in which the glass in various stages of fusion stands to a depth of nearly three feet. Above this seething mass there is a low arch which deflects the long, curling flame as it comes over the bridge from the generators, until it bathes the entire contents of the tank in its Plutonic breath. As the materials of the batch unite and melt alone, they would be for the most part entirely infusible the liquid glass sinks to the bottom of the tank and flows through small openings into the gathering chamber beyond. The glass resulting from the union of sand and alkaline bases is heavier than the crude materials from which it is formed, and consequently seeks the lowest level. In this way the tank, although filled with material in all stages of transformation, has always at the bottom a bath of thoroughly fused glass. The communication between tank and gathering chamber is arranged at such a level that the fluid glass alone can pass from one to the other.

This central gathering chamber and the busy life surrounding it are the points of chief interest to the visitor who wishes to see the scenic part of bottle-blowing, and is willing to take the chemistry and some of the more occult parts of the process on faith. The chamber itself is circular, usually about sixteen feet in diameter, and contains a bath of molten glass nearly two feet deep. The temperature of this fiery lake is kept above the fusing-point by the hot gases which come from the melting tank and rise into the high shaft immediately over the gathering compartment. It takes only from two and a half to three hours for the crude materials of the batch to pass to the condition of perfectly fused glass. This is pretty quick glass-making.

A little sand, a little alkali, a little limestone, and considerable heat have so far been expended, and the result is fluid glass. It is that greater amount of skill which is now needed to transform the glass into a bottle.

There is a series of openings, some sixteen in number, around the sides of the gathering chamber and a little above the level of the molten glass. Through these the glass-blower draws his supply, but he does not dip his blowpipe directly into this glowing reservoir. Such an arrangement would cause too great a loss of heat, besides interrupting the furnace-draught, and would be a source of constant annoyance to the gatherer on account of the impurities which float as a scum on the surface of the bath. To avoid these evils, each gathering hole has its "boot" a rounded hood of fire-clay which surrounds the hole on the inside of the chamber, and extends downward to the bottom of the bath in the shape of an oval cylinder. An opening near the bottom of the cylinder admits the fluid glass into the interior of the boot, and

Fig. 3.—The Operation of "Marvering."

permits it to stand always at the same level there as in the gathering chamber outside. Thus the gatherer draws his burden from this little bucket-like reservoir, but, like the widow's cruse of oil, the supply never gives out.

Outside of the furnace the agencies of heat and chemism are replaced by that of human dexterity. The men work in companies, which are known in the glass-maker's parlance as "shops." And very busy companies they are. They resemble nothing so much as a swarm of bees, as they hurry to and fro about the gathering holes. The condition is one of almost nervous activity. The men toss their blowpipes hither and thither in the operation of forming the bottles, and boys dart in and out of the crowd carrying bottles in all stages of development. There is complete singleness of purpose. They are all intent on turning out the largest number of bottles possible for the pay is largely by the piece. Where the bottles are very small, one man has been known to blow as many as two hundred dozen in a day, but this is exceptional activity.

There are, all told, seven persons in such a shop: three men, of whom two blow the bottles, while a third, the gaffer, forms the necks, and four boys who gather the molten glass, open the molds, and carry away the finished products. The gatherer is a somewhat older boy than the others, and stands in direct line of promotion; is, in fact, a blower or gaffer in embryo. He aspires the others but distantly. One shop is attached to each boot; and occasionally, when work presses, there are two shops to a boot, but this is rather crowding things and is not favorable to the best working. The process begins with the gatherer. His blowpipe is a tube of wrought iron, five or six feet long, and of lighter weight than the pipe used in blowing window glass. He dips the end of his pipe into the molten contents of the boot, and brings out a mass of red-hot plastic glass. If the bottles to be blown are small, one gathering suffices, but, for larger wares, two or even three gatherings may be necessary to get the requisite supply of material on the end of the blowpipe. When the gathering is done properly, this lump of red-hot glass is a perfectly homogeneous mass. Its subsequent fortunes rest with the blower. He takes the blowpipe from the gatherer, and, resting the plastic glass against a marvering table of stone or cast iron, he gives the pipe a few adroit rotations, thus fashioning the glass into an even cylindrical shape. By further rolling it along the edge of the table he forms the smaller prolongation of glass which is afterward to become the neck of the bottle. Lifting the still red-hot glass from the table, he blows through the pipe, forming a small bubble of air in the interior of the mass of glass. This is afterward extended until it becomes the inwardness of the bottle.

The partly fashioned bit of glassware is now introduced into the mold which one of the "shop" boys has already opened to receive it. For convenience in working, the mold is placed on a somewhat lower level than that on which the blower stands. It is made of cast iron, and is commonly formed in two pieces. One of these is stationary, while the other opens outward, its motion being controlled by a foot-lever. When the blower places his incomplete bottle, still attached to the blowpipe, into the mold, he closes the mold with his foot, and blows through the pipe until the plastic glass is everywhere forced against the sides of the mold, and has impressed upon it the form of its prison. Then with a quick motion the blower detaches his blowpipe from the projecting neck of the bottle—the glass is still plastic—hands it over to the gatherer, and with a fresh blowpipe repeats his labor. Such constant blowing largely develops the muscles of the cheek, but the exercise is not unwholesome. It is impossible by methods like these to obtain bottles of uniform thickness, yet the variations are much less than one would suppose.

Fig. 4.—Putting the Bottle in the Mold preparatory to the Final Blowing.

In contact with the iron of the mold the bottle cools very rapidly. Almost as soon as the blower takes away his pipe, the mold may be opened and the bottle removed. The little fellow who does this is called a "snapper." He seizes the bottle with his iron forceps and transfers it from the mold to a pair of scales near by. A small square of asbestus cloth remains permanently on the scale-pan, as contact with the cold iron would be apt to crack the glass. All bottles, except the very small ones, are thus weighed, and any that show either a deficiency or an excess in weight are rejected. There will always be a slight variation, but it must be within narrow limits, not exceeding, for instance, an ounce in bottles intended to weigh seventeen ounces. Comparatively few bottles are rejected for this cause. The bottle of approved avoirdupois is placed in a closely fitting case of wrought iron mounted on a long handle. Only the neck of the bottlers allowed to project. Thus blanketed and mounted, the hot glass is easily handled.

It goes now to the gaffer, to have its neck properly shaped. He is found at no great distance, sitting before a little side furnace which affords three openings—"glory-holes"—large enough to admit the necks of the bottles, and a heated atmosphere of sufficient intensity to make the glass necks plastic and workable.

Fig. 5.—Blowing a Flask in the Air.

Crude petroleum is the fuel used. It is stored in a tank to one side of the furnace, and trickles down, drop by drop, into a tube which brings a strong blast of air from a distant fan. In this way the oil is vaporized, and mixed with such proportions of air that the mixture is highly combustible, and in burning produces an intense heat. Three tongues of yellow flame thrust themselves out of the glory-holes and leap toward the gaffer sitting before them. In England this member of the shop is known as the chairman, a term which refers to his bodily rather than to his official position. He thrusts the necks of the incased bottles into the glory-holes, and then one by one withdraws them from their aureole and forms the necks. This he does by means of a convenient implement known under the generic name of tool. It consists of a central stopper, kept moist with oil, which is thrust into the mouth of the bottle, thus determining its gauge; and of two outside arms of iron, which, by the rotation of the case, the tool remaining stationary, form the smooth ring commonly adorning the necks of glass bottles. The gaffer, like the blower, is a quick workman, and does the finishing for both blowers belonging to his shop. He does not leave his chair, the glass being brought to him and carried away again by the little boys who have been noticed as darting about in such a lively fashion.

The bottle is now finished, so far as its form is concerned, but, like the window-pane under similar circumstances, it would have scant value if sent out into the world in its present condition. It would be too brittle, on account of its sudden cooling, and must therefore first be annealed. This operation is simply one of gradual cooling, and is carried out in ovens or in annealing leers.

Fig. 6.—A View of the Gaffer at Work, showing his Tool and Manner of holding the Bottle when forming its Neck.

The oven is a roomy chamber of brick-work, in which a wood fire is permitted to burn for a couple of hours in the early part of the day. It is opened when the blowers begin work, and during the remainder of the day it is gradually filled with bottles as the different gaffers finish them. At night it is closed and permitted to remain so for three days. At the end of that time the oven has become quite cold, and the bottles are thoroughly annealed.

The leer is a later invention and carries out the same process, only it acts continuously and is in so far an advance. It also consists of a roomy chamber of brick-work, but the fire is permanent and is located at one side of the chamber. A long brick passageway extends for eighty feet from the back of this receiving chamber. The bottles are not piled directly on the floor, but are placed in low sheet-iron cars which move on a track extending the length of the passage-way. As soon as a car is filled, it is moved along the passage-way in order to make room for an empty car in the receiving chamber. In this gradual way the loaded cars are moved along the passage farther and farther from the source of heat, and finally discharge their loads at the cold end of the leer. It takes from forty-eight to sixty hours to accomplish the journey, though this is simply a matter of convenience, as the annealing process itself would not require more than from nine to ten hours, if so long as that.

Ordinarily the bottles, just as they come from the ovens and leers, are ready to be packed and shipped to their purchasers. In case, however, a seal has been blown in the side of the bottle and its prospective contents are of an effervescent character, the strength of each bottle must be carefully tested, as the glass forming the seal is apt to blow out thinner than the rest, and thus be a source of weakness. The testing is carried out by filling the bottle with water and then subjecting it to the pressure of a column of water equal to eighty pounds to the square inch. Only a few of the bottles, however, break under this ordeal.

But in case the bottle has a screw top, as in fruit-jars and the like, or is to have simply a plain ground edge, as in electric-battery jars, it is manufactured with a slight excess of glass on the top. This is known as a "blow-over." In this event the bottle does not pass through the hands of the gaffer, but goes directly from the blower to the ovens or annealing leers. In the grinding department the blow-over is knocked off and the rough edges ground smooth in a rotary grinding machine. In this the bottles or jars are put in upside down, eleven at a time, and have their edges pressed against the face of a large horizontal iron wheel which is rotated by steam-power. The framework in which the jars are held also rotates, and, in addition, each individual jar turns on its own axis. The iron wheel is supplied with a constant stream of sand and water, and this, with the triple motion of the machine, does very effective work. As many as sixty dozen jars can thus be ground in an hour.

The products of such a bottle-factory are as varied as the processes by which they are fabricated. There are large bottles and small bottles, tall bottles and short bottles, thick bottles and thin bottles, ugly bottles and pretty bottles in fine, all sorts of bottles, according to the taste and requirements of the purchaser. He may order anything, from the tiny vial of one-drachm capacity up to the ungainly carboy holding fourteen gallons. He may have any tints desired, from the colorless flint glass through all shades of green and brown and blue to the bottle of absolute blackness. Or

Fig. 7.—The Annealing Leer, as seen from the Front.

he may have any shape or form he pleases. Few if any bottles are kept in stock or made until ordered. Nearly all of the work is the direct filling of orders.

It is only by comparison with the older order of things that one can appreciate the large improvements that have recently been introduced into the process of bottle-making. In the Glassboro works the Ferrari furnace has effected many changes and many economies. I am told, on very reliable authority, that not only is the quality of the glass much improved by the employment of these furnaces, but that in addition the experience of five years has shown their maintenance and operation to be notably less expensive than the old-style pot furnaces. In the matter of fuel the saving is said to have been more than fifty per cent. The repairs have also cost as much less in proportion. When the melting was done in pots, the cost of these alone made an appreciable item in the year's expenses. Each one cost about fifty dollars, and their average life was only two months. Occasionally one was known to last nine months, but for every such exception there were from two to three dozen which failed in less than a month. The four furnaces in operation would require in all about forty pots, and these renewed every two months would mean during the working year an expenditure for pots alone of ten thousand dollars. The present tank furnaces are out of blast during July and August, but the year's repairs are only a nominal expense. The hot season is chosen for renovation for very obvious reasons, though the heat alone is not sufficiently intense to make the cessation of work a necessity.

In thus following the evolutionary process by which a glass bottle is produced, one meets with many ingenious contrivances and many shrewd adaptations of means to ends, but he will scarcely meet with any problem of quite such deep interest as that presented by the people who carry out this process. Particularly is one struck with the large number of boys, scarcely more than children, who are employed in such a factory. About the furnace proper there are even more boys than men. The law does not permit the employment of children under twelve years of age, but exceptions are sometimes allowed by the labor inspector in case a boy has a widowed mother, or some other particular demand upon his early activity. New Jersey further attempts to protect her children by making an annual school attendance of five months compulsory for them. In the glass-blowing districts this requirement is met by the establishment of night schools supported by the State. The term lasts only for the allotted five months, the daily session being for two hours, from half-past six to half-past eight o'clock. My own limited observation of the working of night schools has led me to believe that they are but poor substitutes for work done earlier in the day when the boys are fresher and more buoyant; but the superintendent of a large factory, to whom I spoke on the subject, was of the opinion that these childish glass-workers are doing very satisfactory work in such schools. It is hard, nevertheless, that childhood should be made so short, and that the work-a-day life should begin so early for these little people. They seem, it is true, a very happy, merry set of youngsters, and, if one may judge from the tricks they are constantly playing on one another, they manage to get a fair share of boyish fun; but they can not fail to lose much in being so soon harnessed. As a class, these lads seemed to be finer looking and in many ways better conditioned than the older workers, so that one would naturally fancy that the hard work was leaving its landmarks. Men who have known them longer tell me, however, that it is a new generation, and one that has been reared under more favorable conditions of life.

They are comparatively well paid. The little boys make three dollars a week, and the larger ones six; modest sums admittedly; but large enough under the circumstances of country life to permit a little laying by. I felt curious to know what aspirations were most favored in such a community, and to what ideals the boys looked up. The story was soon told: to become glass-blowers, and to have plenty to eat that was all; a life centered about bottles. Yet, among so many bright-faced lads, there are doubtless many of considerable promise, could their imaginations only be fired by some well-directed effort. Some one with a passion for culture and a big human heart could do great things, it seemed to me, with such quick, observant material.

With the older workers the dice have been cast, and life is well crystallized. It has left them divided into two classes: the green-glass blowers, who are chiefly Americans, and the flint-glass blowers, who are more largely Germans. Both bodies of men are closely organized, and as a result make excellent wages. The union to which they belong will not permit more than two apprentices a year to a single furnace. Such a regulation, with the annual increase of the industry and the inevitable deaths, practically excludes competition. The blowers make on an average five dollars a day. In rare cases as much as three hundred dollars a month has been paid to a single man. So large returns, however, are only possible for blowers and gaffers. The other members of the shop, as well as the numerous helpers employed in the conduct of such large enterprises, receive regular wages.

One other feature deserves mention. Throughout the entire works there is observable that marked tendency of modern industrial life to substitute continuous, automatic processes for those which are periodic and manual. The continuous annealing leer is taking the place of the oven; the steady flow of gaseous fuel is replacing the oft-repeated shovelful of coal; the continuous melting tank has been substituted for the discontinuous reservoir system represented by the crucible pots; the uninterrupted automatic charging of the furnace is about to do away with the manual feeding of the batch every three hours; and similarly, in all departments, the change is in progress. The operations of blowing have not yet been made automatic. Bottles but an inch long are still produced by the blower's breath, and little boys dispose of them one by one. But it is not improbable, in spite of the difficulties in the way, that a patent bottle-blowing machine will some day take the place of the army of workers who now swarm around the gathering chamber of a glass-furnace. Such a machine already exists in the brain of a man. When it is materialized into a working fact, the last step in perfecting the evolution of a glass bottle will have been taken, and any further development will be along lines already laid down.