Popular Science Monthly/Volume 62/November 1902/The Development of Economical Utilities for Handling Raw Material

| THE DEVELOPMENT OF ECONOMICAL UTILITIES FOR HANDLING RAW MATERIAL. |

By WALDON FAWCETT.

THE existence in crude form of some elementary devices for hoisting or otherwise handling certain classes of raw material, notably stone and logs, dates back many years, but it has been within the past decade and a half that there has taken place that remarkable progression which has constituted one of the most impressive achievements of the modern engineering world. Not only is bulk material, practically without limitation as to weight, hoisted to any height desired, but it has been rendered possible to transfer commodities at high speed for either long or short distances, and thus the mechanical operatives of the modern industrial world secure the trilogy of an economy of time, a saving of labor and the conservation of expenditures.

Easily the most interesting as well as the most significant advancement in this broad field is found in the introduction of improved methods for the handling of those two most important commodities coal and iron, the latter embracing of course a variety of forms from iron ore to finished steel. Indeed, in the case of the most useful of metals there has been evolved a cordon of mechanical devices, the functions of which so supplement each other that from the time the ore leaves the mine until it has been transformed into marketable iron or steel the factor of manual labor directly applied, is practically eliminated.

The initiatory machine in this chain is found in the steam shovel which takes the iron ore from the 'open pit' mines of the Lake Superior district and later is called into requisition to transfer the ore from the stock piles at the mines to the railroad cars provided to carry it either direct to the blast furnaces or to the vessels wherein it will be given water carriage to the Great Lakes. The steam shovels for the latest approved practice range in weight from fifty-five to ninety-five tons and in this feature alone is afforded ample evidence of progress, for but a few years since the shovels of thirty-five or forty-five tons weight were deemed sufficient for all the exactions imposed by this work. The shovels now in use have dippers ranging in capacity from two and one half to five yards, and something of the celerity of movement with which they are operated may be appreciated from the fact that on many occasions ordinary railroad cars are loaded with ore and pushed out of the way of the machine at the rate of one every two minutes.

In the unloading of the immense cargo-carrying vessels of the inland seas wherein the iron ore is conveyed from the Lake Superior mining district to the ports adjacent to the blast furnaces of the Middle West are employed the various forms of hoisting and conveying apparatus, all of American origin, which probably constitute the most famous of all the installations for transportation purposes. In this field of activity methods advanced, at a single step, from the old plan of unloading the vessels by means of wheelbarrows and permanent trestles to the bridge tramway structures which are up to the present date in almost universal use.

The conspicuous elements in any such installation embrace the elevated tramway—spanning the dumping ground or railroad yard and

connecting it with the vessels—the trolley or carriage traversing this tramway and the system of mechanism by which the whole is operated and controlled. Such an apparatus is operated, of course, by a motive power located beyond the limit of travel, and while the operation is at every stage subject to the control of an operator, a large proportion of the important functions are automatic, the positive movements of the parts through such operations being derived entirely from the bodily movement of the apparatus itself, while actuated by momentum, gravity or the direct action of the hoist rope. Attached to the trolley of each machine is an automatic dumping-tub or bucket, the discharge of which may be made at the will of the operator, either at the

Bridge Tramways.

Cantilever Aprons Extending over Vessel

full height of the tramway or by an automatic deflection of their motion and with no appreciable loss of speed the buckets may be caused to descend and discharge their contents at any point below the tramway.

The bridge tramways are usually built in plants or groups of three or four bridges which may be supported on either single or double piers. The tramways are, as a rule, provided with hinged aprons designed to extend over the vessels and very frequently cantilever extensions are provided at the opposite end, so that the buckets are enabled to serve a space of 300 to 350 feet in width. The operation of the tub or bucket is effected by means of a wire cable connected with a drum in the engine room, and the engine is usually of the double cylinder type. The piers supporting a bridge tramway are on wheels, and it is thus possible to skew or move sideways the entire structure, in order to bring the bridges in line with the hatches of the vessel being unloaded. This type of machine hoists the bucket of ore from the hold of the vessel, conveys it to any desirable point on the tramway and automatically dumps the material on the dock or into waiting railroad cars.

As indicating the capacity of the bridge tramway, it may be cited that a plant of three bridges will readily handle 1,200 tons of ore in a day of ten working hours, hoisting the material, conveying it a distance of 100 to 150 feet and dumping automatically. In the case of the bridges of exceptional length a round trip can be made from the  Clam-shell Bucket of Automatic Unloader. hold of the vessel to the extreme end of the cantilever and back again, a distance of 600 feet in one minute, and in actual operations a rate of 45 seconds per trip has been maintained for hours at a time. The buckets or tubs for conveying ore are usually of one ton or a ton and a half capacity. There are several modifications of the bridge tramway system, notably cable tramways in which wire cables are substituted for the bridges and what are technically known as 'fast plants' wherein instead of the long bridges there are extremely short ones with tramway projections over the vessel and cantilever extensions over the railroad tracks on the dock, the effect of this short haul being to reduce tremendously the lapse of time necessary for the transference of raw material from vessels to cars.

Clam-shell Bucket of Automatic Unloader. hold of the vessel to the extreme end of the cantilever and back again, a distance of 600 feet in one minute, and in actual operations a rate of 45 seconds per trip has been maintained for hours at a time. The buckets or tubs for conveying ore are usually of one ton or a ton and a half capacity. There are several modifications of the bridge tramway system, notably cable tramways in which wire cables are substituted for the bridges and what are technically known as 'fast plants' wherein instead of the long bridges there are extremely short ones with tramway projections over the vessel and cantilever extensions over the railroad tracks on the dock, the effect of this short haul being to reduce tremendously the lapse of time necessary for the transference of raw material from vessels to cars.

In the case of all forms of bridge tramway apparatus it is necessary to employ large gangs of men to fill by means of hand shovels the tubs or buckets carried by the trolleys and naturally therefore there is in the transportation world a tendency to regard with favor the latest inventions in the line of machinery for the rapid unloading of iron ore, namely, the automatic unloaders which dispense entirely with human energy directly applied in the unloading operations. The fundamental principle of all the automatic unloaders is found in the operation of some sort of a clam-shell bucket which is let down into the hold of a vessel with its iron jaws extended and, closing them, retains in its grasp

one or more tons of ore while it is lifted from the hold and run back to a stock pile or waiting railroad cars after the manner of the bucket of the bridge tramway. The original automatic unloader, introduced only two or three years ago and in active use to-day, weighs several hundred tons, and is equipped with a great mast to be lowered through the vessel hatch and from which depends a clam-shell bucket capable of holding ten tons of ore. The later patterns of unloaders, automatic in their action, are fitted with excavating buckets of only about one ton capacity, and which therefore permit of hoisting and transference by wire cable instead of necessitating the ponderous iron and steel structure required to support the mast and clam-shell in the original design.

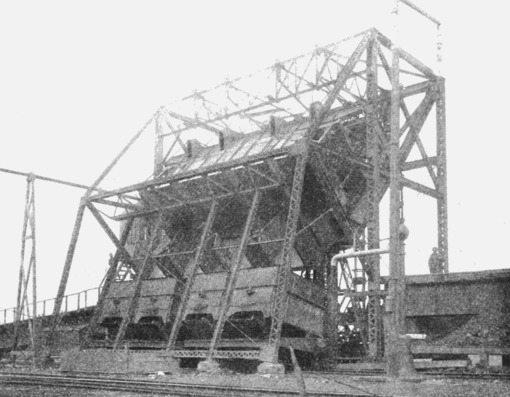

Bridge tramways similar to those in use on the ore-unloading docks are employed in the furnace yards to convey the ore from the railroad cars to stock piles, and a patent furnace hoist automatically conveys the ore together with the coke and limestone to the top of the blast furnace and performs the operation of 'charging.' The automatic hoist consists of an inclined iron-trussed bridge reaching from the floor of the stock house to the top of the furnace shell and from thence over the top opening of the furnace. On this bridge is laid a track of T rails on which travels a skip or ear, containing the charge of one to three tons as may be desired. The track is so arranged at the top that the contents of the car are automatically dumped into the hopper on the arrival of the car at the top. The skip car is hoisted or hauled to the top by a double engine with a friction clutch drum.

The exigencies of handling great quantities of coal for shipment have been quite as productive of ingenious mechanical devices as have the requirements of the iron industry. Bridge tramways have been employed extensively for both loading and unloading of fuel, and in the case of anthracite coal clam-shell buckets and bucket shovels which scoop up the coal have been introduced in connection with the bridge tramway instead of the ordinary bucket. However, preeminent among all the varied forms of coal-handling apparatus stands the car-dumper, a class of machine, each step in the evolution of which has been marked by a distinct type of apparatus, but which has finally reached a point of development where it is possible for one of these machines to hoist a loaded coal car into position alongside a vessel, pour its contents into chutes communicating with the hold and return the empty car to the track in the elapsed time of one minute. In the case of the most approved styles of car-dumpers the loaded car is clamped to the track in a sort of cradle in such manner that it may be turned completely over and yet by means of a reciprocating movement on the part of a huge pan suspended in the framework of the machine and connected with the chute leading to the hold of the vessel, the coal is transferred with a minimum amount of breakage.

A class of coal-handling machinery in which recent years have witnessed great development is found in the various forms of chain elevators and link-belt machinery. This form of equipment is used extensively at railroad coaling stations designed to supply fuel to locomotives. In a representative installation one run of the upper conveyor is for stocking the coal and the other for distributing it into chutes, while the lower conveyor delivers coal from storage. Each conveyor is an endless chain interspersed with metal partitions forming pockets, is 600 feet in length and has a capacity of 120 tons of coal per hour. In many stations an inclined conveyor delivers coal from cars to a distributing conveyor and the latter apportions the fuel among twelve or more chutes. Conveyors of this same general type are also used for transferring coal from mine to storage pile or cars. For such utilization there is selected apparatus of great simplicity of design, namely, a scraper conveyor with steel nights of proper shape attached to the chain and drawing the material along in a steel trough. Some installations of this character have a length of about 300 feet and a capacity of four tons of coal per minute.

Modifications of the belt conveyor are now to be found in use in almost every branch of the industrial domain, being put to a variety

of uses ranging all the way from the movement of grain to the carriage of logs and stone. Moving platforms, constructed on the endless chain plan, also have an important place among the utilities for handling bulk commodities. Likewise is there extensive employment of traveling cableways and aerial ropeways wherein either the impetus of gravity or hauling ropes are depended upon for propulsive power. Some of the recently installed traveling cableways have a span exceeding 700 feet and are adapted for handling loads of from five to ten tons. The most modern of all of these aerial transportation systems is that designated 'telpherage,' whereby electricity is relied upon as an operative force. In this class of installations the overhead trolley system of the ordinary electric railway has simply been adapted to the rope railways, and by the provision of an ingenious device the electric car or telpher is enabled automatically to slacken speed when approaching a curve, resuming the normal rate of travel when the dangerous point has been passed.

The part which cranes of various kinds have played in the solution of the problem of the economical handling of raw material of various kinds is indeed an important one and there has been a steady increase in capabilities until there are now in service in the United States a number of cranes each of which is capable of handling a load of one hundred tons.

Easily the most remarkable of all the cranes yet constructed are the great balanced cantilevers invented by Alexander Brown, an American. The cantilever crane is applicable to a large range of work and is the

most perfect machine yet devised for use in handling armor plate and other heavy parts in ship-yards and manufacturing establishments generally. The cantilever is divided into two arms, which in some instances have a span of over 350 feet. By means of trolley and hoist block, mounted on the cantilever of the crane, the load can be hoisted from the ground and traversed from one end of the cantilever to the other, the pier or base of the crane being so arranged that the load passes through it. These cantilever cranes have an automatic counterweight running on a track along the bridge and above the hoisting trolley, and connected by ropes to the latter, so that whatever the position of the hoisting trolley on one arm of the crane, the counterweight at all times automatically occupies a similar position on the other arm. The latitude of the operations of the apparatus is further broadened by reason of the fact that the entire crane travels by its own power up and down the track or trestle on which it is mounted. A crane of this type is capable of marvelous speed. A load of fourteen tons may be hoisted at a speed of 200 feet a minute; the trolley travels back and forth along the cantilever arms at a speed of 600 feet a minute; and the entire crane has sufficient propulsive power to enable a speed of 750 feet a minute in traversing the track or trestle.

In conclusion attention must be given to the so-called lifting magnet, the most wonderful of all the new appliances for handling weighty raw material. The electro-magnet, by the aid of electricity, performs on a large scale something of the same function as the toy with which children have long been familiar. One magnet will elevate a mass of metal weighing two tons and it is possible to use several magnets simultaneously in handling a particularly heavy steel plate or bar. This plan of handling material also possesses immense economic advantages, inasmuch as a single mechanic is usually in charge of the crane to which the magnets are attached.