Railroad Accident Report 92-01/Investigation

NATIONAL TRANSPORTATION SAFETY BOARD

WASHINGTON. D. E. 205513

RAILROAD ACCIDENT REPORT

DERAILMENT AND COLLISION OF AMTRAK PASSENGER TRAIN 66 WITH MBTA COMMUTER TRAIN 906 AT SACK BAY STATION BOSTON, MASSACHUSETTS

DECEMBER 12, 1990

INVESTIGATION

The Accident

editAt 10:30 p m on December 11, 1990, National Railroad Passenger Corporation (Amtrak) passenger train 66 departed Washington. D C, for Boston, Massachusetts The operating crew changed at New York City, New York, and again at New Haven, Connecticut The New Haven to Boston operating crew. comprising a locomotive engineer, an apprentice engineer, a conductor, and two assistant conductors, reported for duty at 430 a m on December 12, 1990, at the New Haven station (mile post[1] [MP1 72 3) on Amtrak‘; Boston division As part of Amtrack's locomotive engineer training Program, the apprentice engineer had been assigned to the crew

Between Washington and New Haven, electric locomotives had powered Amtrak train 65 These electric locomotives were removed and replaced with a diesel-electric, two—unit F-SOPH locomotive (272 and 366), from the New Haven motor storage area

The locomotive crew received a list of speed restrictions for their trip and then performed a ground (walkaround) inspection They boarded the two-unit locomotive at 4:36 a m, reviewed the cab defect and inspection cards, and checked the radio They also did an airbrake test, a plying and releasing the locomotive brakes The crew noted no exceptions to the condition of the locomotive The locomotive engineer then assigned the apprentice engineer to operate the locomotive, an the apprentice engineer did so. under the direct supervision of the locomotive engineer, for the entire trip

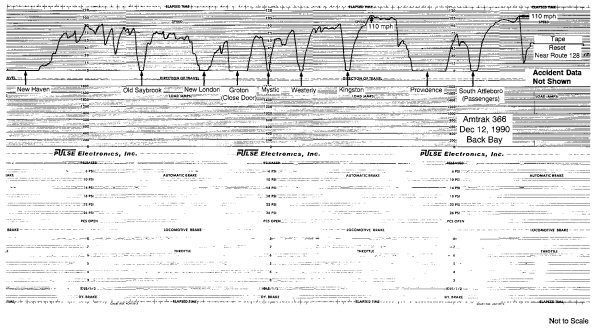

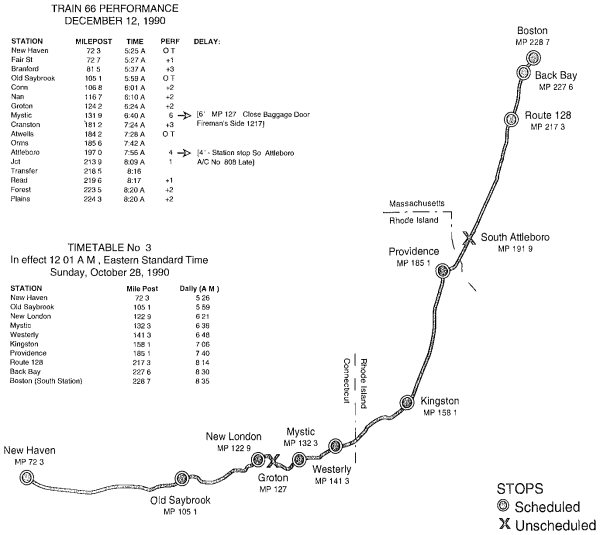

With the front of both units headed eastward, the locomotive moved from the motor storage area to the passenger station and was coupled to the 10-car passenger train A car inspector assisted in the coupling procedure and made the necessary air hose connections between the locomotive and the east (first) car at the train From the rear of the train, the car inspector made an airbrake test The apprentice engineer applied the automatic brake valve to set and then release the train airbrakes The car inspector made a ground ins action of the train, observed that the airbrakes were released, and then release the train for departure At 525 a m Amtrak train 66 left New Haven on schedule Shortly after leaving New Haven, the event recorder data registered a moving airbrake test The apprentice engineer stated that the brake system functioned properly According to the Amtrak dispatcher‘s office train performance records, the train continued on schedule and the crew operated in compliance with the speed limit, until two unscheduled station stops at Groton, Connecticut, and Sout Attleboro, Massachusetts The Amtrak timetable showed the maximum authori1ed speed for Amtrak train 66 as 100 mph. The event recorder data registered that Amtrak train 66 operated at speeds up to 110 mph between Kingston and Providence and between South Attleboro and Route 128. (See figure 1.)

Amtrak train 66 made its regular station stops at Old Saybrook, New London, Mystic, Westerly. Kingston, and Providence According to the locomotive engineer, he moved from the firernan's seat on the left side of the locomotive to a position behind the apprentice engineer to supervise and instruct him in the proper brake application at each station stop. The locomotive engineer added that the method of operation he used when instructing an apprentice engineer was to "talk" that apprentice engineer through every station. Both engineers reported that all stops were normal and noted no exceptions to the handling of the train en route. The locomotive engineer stated that he cautioned the apprentice engineer about applying the brakes and slowing early for the stop at Westerly and then accelerating too fast on departing Kingston

Both engineers and the conductor described the trip as normal except for a radio report from the operator at Groton tower (MP 124 2) that a door was open on baggage car 1217, which was the second car behind the locomotive The locomotive engineer advised the apprentice engineer to stop on straight track east of Groton near MP 127 The conductor and an assistant conductor closed the door on car 1217. After a 6-minute delay, Amtrak train 65 resumed its eastbound trip

According to the Amtrak dispatcher's office train performance records, Amtrak train 6 was 6 minutes late at Mystic (MP 131 90) but was on schedule at Atwells (MP 184.2). The dispatcher notified the traincrew to stop at South Attleboro (MP 192) to board passengers. The stop at South Attleboro required about 4 minutes Amtrak train 65 made its regular station stop at Route 128 (MP 217 3) on schedule (For stopping information see figure 1)

After departing Route 128, the apprentice engineer noticed that a continuous air~blowing sound had developed near the automatic airbrake valve. He reported this sound to the locomotive engineer, who immediately moved to a position behind the apprentice engineer. The locomotive engineer described the sound as a hissing and said that it happens frequently, adding, "Apparently it's a little piece of dirt in the brake valve it at clears itself, usually no big deal". The locomotive engineer stated that he used the automatic airbrake valve to make an application and release of the brakes, and the air—b|owing sound stopped. The apprentice engineer said that when the air blowing sound began again, he made a set and release of the automatic airbrake valve, and the sound again stopped. Event recorder data did not show these brake valve movements.

In preparation for the stop at Back Bay station (MP 227 6), the locomotive engineer said that he advised the apprentice engineer to begin applying the automatic airbrakes when the Ruggles Street station (MP 226 5) platform came into view. According to the apprentice engineer, while the train operated at 94 mph

with the throttle in run 4 or 5 position,[2] he made a minimum 10- or 12-pounds per square inch (psi) service application of the automatic airbrakes shortly before passing the eastbound wayside automatic block signal (MP 226 2) west 0 Ruggles Street station (See figure 2) He stated that he then released the locomotive independent brake an reduced the throttleto run 1 or 2 position The locomotive engineer said that the brakes did not exhibit the normal reaction and that the train slowed only a little when it should have slowed more

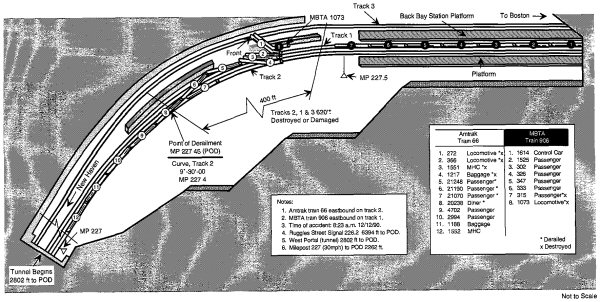

The locomotive engineer instructed the apprentice engineer to make a further brake application, and the apprentice engineer made a 32-psi full-service application while passing the Ruggles Street station platform The locomotive engineer stated that they could sense that the train was not slowing down sufficiently According to the apprentice engineer, the locomotive engineer made an emergency application of the automatic airbrakes, The train moved eastward into the tunnel at MP 227 on track 2 and entered the 90 30‘ right curve near MP 227 4, 200 feet from the point of derailment (POD) The locomotive engineer said that the train entered this curve "hard" Neither the locomotive engineer nor the apprentice engineer noticed the train speed at that time. The speed restriction on all tracks (l, 2, and 3) through Back Bay station from MP 227 to MP 228 3 is 30 mph (See figure 2)

On board Amtrak train 66, neither the conductor, two assistant conductors, nor a deadhead conductor (a railroad employee traveling to a work assignment) heard an application of the airbrakes before the accident. The train 66 conductor felt the brakes apply on the train. The other crewmembers were able to state only that the train was slowing for the Back Bay station

As Amtrak train 66 moved into the curve, the locomotive crew felt the locomotive tip to the left toward track 1 As Amtrak train 66 approached the west end of the Back Bay station platform, its locomotive crew saw locomotive 1073 of the Massachusetts Bay Transit Authority (MBTA) commuter train 906 on track 1 The locomotive crew reported that events then became unclear until after the collision with the META train 906 (See figure 3)

Shortlyy before 7 45 a m , the MBTA train 906, comprising one control car, six coaches, an one locomotive, had departed Stoughton, Massachusetts, eastbound for South Station, Boston The MBTA train 906 was a push/pull operation; the locomotive was on the rear (west end) of the train in the pushing mode The MBTA train 906 operated with an Amtrak crew comprising a conductor, three assistant conductors, and a locomotive engineer The locomotive engineer was operating the train from the control car cab, which was equipped with locomotive controls, at the front (east end) of the train. The locomotive engineer stated that the MBTA train 906 was almost stopped on track 1, moving about 5 to 10 mph, at the time of the accident He was standing at the controls in the cab, felt the collision, and was knocked to the floor Not knowing exactly what had happened, he made an emergency radio call to the dispatcher.

At 8 23 am in the Boston train dispatcher's office, the Centralized Electrical and Traffic Control (CETC) system illuminated a “track occupied" light (TOL) for track 3 at Back Bay station. The dispatcher stated that before the TOL illuminated,

track 3 Shortly after noticing the TOL, the dispatcher heard the Mayday radio transmission from the locomotive engineer of MBTA train 906 advising of an emergency at Back Bay station and to hold all trains. The dispatcher heard no conversation from the crew of Amtrak train 66 and was unable to contact them on the radio.

At 8:24 a m., from the Back Bay station platform, a passenger from MBTA train 906 telephoned the 911 operator for the Boston Emergency Medical Service (EMS). The first EMS units arrived at 8:28 a.m. The EMS personnel and both traincrews began evacuating the injured passengers and injured crewmembers. After the accident, the conductor of MBTA train 906 described the evacuation as orderly. The EMS transported 278 people with injuries to local hospitals. Among the 14 admitted were the locomotive engineer and apprentice engineer from Amtrak train 66 and 7 firefighters. No fatalities occurred as a result of the accident.

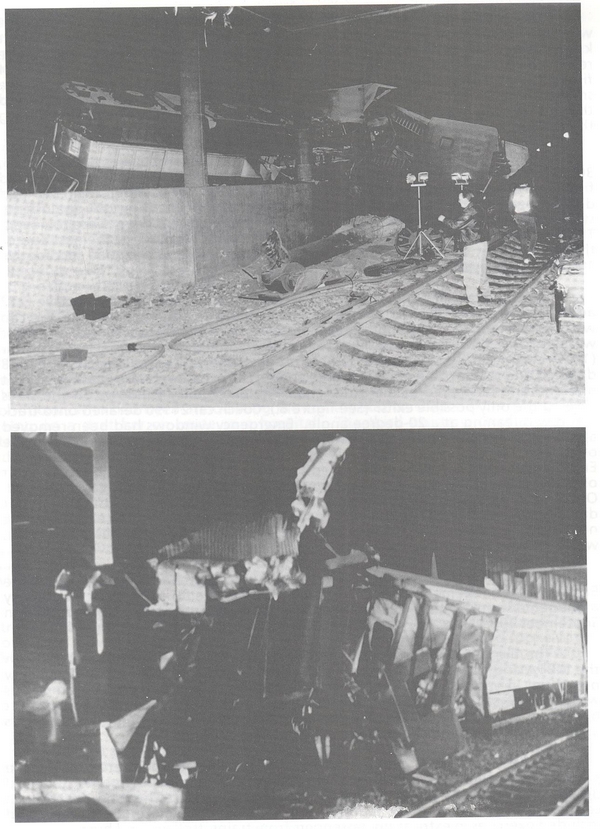

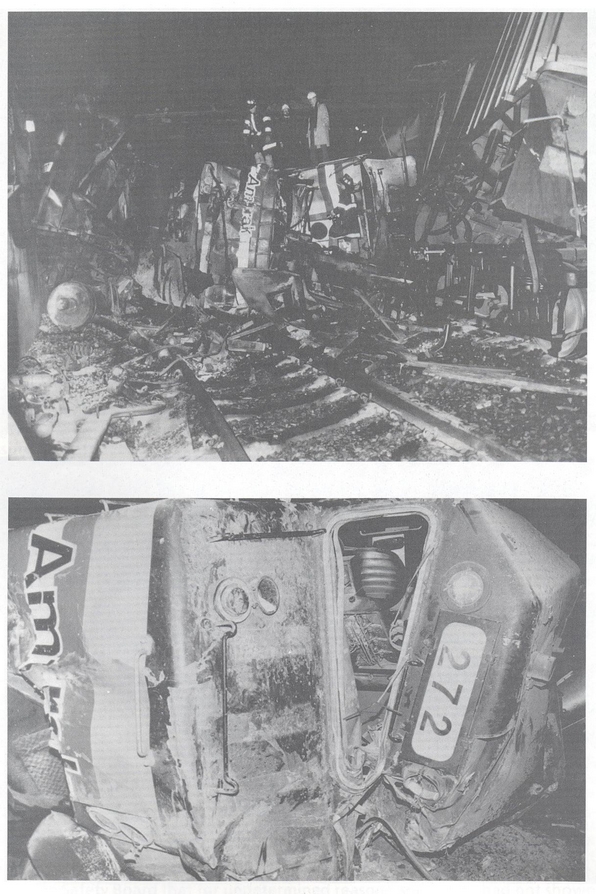

Both trains sustained massive equipment damage. The fuel tank on Amtrak locomotive 366 broke loose, and a diesel fuel fire ensued. The fire department quickly extinguished the fire, but moderately heavy smoke and minor fire damage resulted Exhaust fans in the tunnel reduced the smoke and removed it completely after the fire was extinguished.

Injuries

edit| Injuries | Amtrak Train 66 Crew | Amtrak Train 66 Passengers | MBTA Train 906 Crew | MBTA Train 906 Passengers | Other | Total |

| Fatal | 0 | 0 | 0 | 0 | 0 | 0 |

| Serious | 2 | 3 | 0 | 3 | 6 | 14 |

| Minor | 5 | 40 | 5 | 388 | 1 | 439* |

| None | 0 | 147 | 0 | 509 | - | 656 |

| Total | 7 | 190 | 5 | 900 | 7 | 1,109 |

* After the accident, an additional 175 passangers reported injuries.

Damages

editOn Amtrak train 66, the two-unit locomotive and five cars were destroyed, and one car was significantly damaged. On MBTA train 906, the locomotive and one car were destroyed.

Tunnel structure damage required the replacement of two concrete support columns, six bridge girders, and bridge decking, the resurfacing of Dartmouth Street; and repairs to the support column wall and utilities. Signal cable damage was minor.

Amtrak and the MBTA estimated the damages as follows:

| Locomotives and equipment | $9,235,000 |

| Track and Signal | 322,325 |

| Tunnel and street | 2,877,675 |

| Clearing | 240,000 |

| Total | $12,675,000 |

Crew Information

editMBTA Train 906—Before reporting for duty at 4:10 a.m. on December 12, the crew had been off duty for more than 8 hours and were rested in accordance with the Hours of Service Act. The crew was qualified by Amtrak for their respective positions and had attended an operating rules and instructions class in the previous 12 months.

Amtrak Train 66.—Before reporting for duty at 4:30 a.m. on December 12, the crew had been off duty for more than 8 hours and were rested in accordance with the Hours of Service Act. The crew was qualified by Amtrak for their respective positions and had attended an operating rules and instructions class in the previous 12 months.

The locomotive engineer of Amtrak train 66 had been hired by the New York, New Haven and Hartford Railroad (NYNH&H) in August 1957. The Penn Central Railroad, which had acquired the NYNH&H in January 1969, promoted him to locomotive engineer in October 1969. He had been operating in the same territory (now part of the northeast corridor) his entire career in February 1976, he served as a Penn Central classroom instructor who demonstrated the operation of locomotive equipment.

In September 1976, Amtrak employed him as a road foreman. In this supervisory position, he trained and qualified locomotive engineers for passenger service. On January 16, 1979, while moving locomotives, he was distracted when talking to a traincrew and proceeded past a stop signal at Pelham Bay, New York Amtrak dismissed him as a road foreman. He then exercised his seniority rights, returned to Conrail as a locomotive engineer, and operated Amtrak passenger trains under contract to Conrail. When Amtrak hired its own locomotive engineers in January 1983, he transferred to Amtrak

On March 9, 1990, the Metro-North Commuter Railroad banned the locomotive engineer for life from operating on its trackage (New Haven to New Rochelle, New York), except New Haven terminal, for noncompliance with operating rules While resetting a relay switch in the locomotive, he had passed a stop sign. In addition to the ban, the locomotive engineer was suspended and held off duty without pay for 30 days by Amtrak.

On April 9, 1990, the locomotive engineer returned to Amtrak service as a locomotive engineer on the Boston division, operating trains from New Haven to Boston. He had been working Amtrak train 66 on regular assignment since the end of October 1990. His regular schedule was Tuesday trough Saturday, with Sunday and Monday off. On Monday, December 10, 1990, the locomotive engineer, who lives alone in New Haven, had no special activities. On Tuesday, December 11, he deadheaded to Boston on Amtrak train 66 to meet his regular assignment on Amtrak train 153 from Boston, departing 11:15 a.m., to New Haven, arriving 1:36 p.m. He went home and rested, remaining off duty for more than 14 hours 54 minutes. On Wednesday, he reported for duty on Amtrak train 66 about 4:30 a.m.

In July 1973, Amtrak hired the apprentice engineer as a ticket clerk, and in August 1987, he transferred to a position as engine attendant at New Haven. He entered Amtrak's locomotive engineer training program on June 11, 1990, and made regular physical characteristic training trips over the road, until September 13, 1990. From June 11 to July 9, 1990, he observed between New Rochelle and Harold, New York, from July 10 until August 8, between New Haven and Penn Station, New York; and from August 13 to September 13, between New Haven and Boston. On September 17, 1990, he entered Amtrak's engineer training school, which he completed on November 9, 1990. He took 16 tests in the school on which his grades ranged from 75 to 100 percent, except in train handling/operations, on which he scored 55 percent. At the end of the formal classroom training in the school, he was sent to the locomotive simulator facility at the Illinois Institute of Technology (IIT), Chicago, Illinois, where he received passenger train operation training. His simulator operating scores at the end of this training were 100 percent for rules compliance, 78.56 percent for train handling technique, and 30 percent for train handling efficiency.After a 4-week vacation, the apprentice engineer returned to the training program. On December 10 and 11, he completed two round trips as part of the on-the-job training (OJT) phase of train operations. About noon on Monday, December 10, he reported to New Haven for his first OJT trip on Amtrak train 168, which arrived in Boston about 2:25 p.m., he returned to New Haven on Amtrak train 193, arriving about 9 p.m. About 4:30 a.m. on Tuesday, he reported to New Haven for his second OJT on Amtrak train 66, which arrived in Boston about 8:30 a.m.; he returned to New Haven on Amtrak train 153, arriving about 1:30 p.m. He went home and rested, remaining off duty for 14 hours 15 minutes before reporting back for duty. About 4:15 a.m. on Wednesday, the apprentice engineer reported for his third OJT on Amtrak train 66. This trip was the third one on which the apprentice engineer operated the locomotive into Back Bay station and the first time he operated into Back Bay station from New Haven to Boston with this engineer. The engineer and apprentice had been acquainted for over 15 years.

Train Information

editMBTA Train 906—The MBTA commuter train 906 comprised one control car (1614), six passenger cars (1525, 302, 326, 347, 333, and 315), and one locomotive (1073).

MBTA train 906 was configured for push/pull service, which allows trains to make round trips without repositioning the locomotive unit. A locomotive is at one end and a control car is at the other end of the consist. The locomotive provides the power, which the locomotive engineer controls either directly from the locomotive or remotely from the control car. When the locomotive engineer operates from the control car, the train is in the push mode, when he operates from the locomotive, the train is in the pull mode. At the time of the accident, MBTA train 906 was in the push mode.

Amtrak Train 66.—Amtrak train 66 comprised a two-unit diesel-electric locomotive (272 and 366), a material handling car (1551), a baggage car (1217), three passenger cars (21248, 21190, 21070), a dining car (20238), two passenger cars (4702 and 2994), a baggage car (1188), and a material handling car (1552).

Manufactured by the Electro-Motive Division of General Motors Corporation, each locomotive unit was a four-axle, 3,000-horsepower, model F40PH with an 1,800-gallon diesel fuel tank. At the time of the accident, each one carried about 1,500 gallons of diesel fuel. According to the design data calculations, 40PH locomotive units carrying 1,500 gallons of fuel have a turnover speed of about 59 mph in a 9° 30' curve. They were equipped with blended dynamic brakes, automatic airbrakes, locomotive independent brakes, and continuous cab signals that had speed control, event recorders or speed tapes, and radios.

Tunnel, Signal, and Track Information

editTunnel—At the west end of the Back Bay station platform, the tunnel is approximately 86 feet wide. The derailment occurred at MP 227.45, where the tunnel is approximately 62 feet wide in a 9° 30' curve. The three main tracks (1, 2, and 3) run south to north Between tracks 1 and 3, a 3-foot thick, 8 1/2-foot high concrete crash wall with support columns restricted the width of the tunnel for tracks 1 and 2 to approximately 36 feet. The passenger loading platforms are between tracks 1 and 3 and on the south side of track 2.

Signals—The automatic block and control signal indications from the CETC system in the Boston train dispatcher's office govern train movements through Back Bay station. Control for train movement on main tracks is by signal indication, which operates trains in both directions using wayside automatic block and locomotive cab signals.

The automatic speed control system, which functions in signalized territory, is connected to the locomotive cab signal, it is independent of and not connected to the locomotive's speedometer and event recorder. If the locomotive engineer fails to reduce speed to the authorized level in cab signal territory, the speed control automatically triggers a brake application to slow and stop the train Signal 226 2 at Ruggles Street was not coded to provide the 30-mph speed restriction at MP 227.

Before the accident, the train dispatcher had routed Amtrak train 66 on track 2 for "clear, proceed" signals. The locomotive crew on Amtrak train 66 stated that both the locomotive cab signal and the wayside automatic block signal at MP 226.2 displayed "clear, proceed" aspects, indicating a clear track ahead and authorizing Amtrak train 66 to proceed at the maximum track speed of 100 mph. The train was authorized to operate at that speed until MP 227, where the speed restriction is 30 mph and remains in effect until MP 228.3. At the approach to the 30-mph speed restriction at MP 227, no speed signs were posted to warn of the restricted speed ahead.

Track—Built in 1987, the track is 132-pound continuous welded rail with 24-inch centered concrete crossties. It is ballasted to the concrete tunnel floor with 24-inch deep crushed rock Near the POD, the north rail is fitted with an operative wheel-flange lubricator about 750 feet west of the curve.

The MBTA owns the track, and Amtrak maintains it for trains operating at speeds up to 100 mph. Amtrak performs scheduled track inspections twice weekly, at intervals of at least 1 day, and does daily walking inspections of concrete ties. In May 1990, the Federal Railroad Administration (FRA) had inspected the track and noted no defects in the derailment area. An ultrasonic internal rail defect inspection of track 2 on October 20, 1990, also revealed no defects in the derailment area. On December 11, 1990, Amtrak conducted the last track inspection before the accident and found no defects in the derailment area.

Postaccident Track Examination—The POD was at MP 227.45 on track 2 Derailment marks on track 2 were approximately 2,262 feet past MP 227 inside the west portal of the tunnel and approximately 438 feet from the station platform The initial derailment marks were on the north end of three crossties, approximately 14 feet east of the transition point from straight to curve on track 2.

At the initial derailment marks on track 2, both rails remained undisturbed on the ties Beginning 250 feet before the POD, the track was forced approximately 1 inch out of alignment for 62 feet to the south. The track immediately east of the POD was heavily damaged for approximately 30 feet; beyond this area, the track was undisturbed for approximately 120 feet leading into the area where the cars came to rest on track 2.

Approximately 45 feet east of the POD, derailed cars from track 2 forced track 1 northward against the support column crash wall, heavily damaging some 400 feet of track Derailed cars first struck the crash wall 53 feet east of the POD. The wall has an 80-foot gap, which is about 140 feet east of the POD, to accommodate the Dartmouth Street overhead bridge structure. When the lead locomotive on Amtrak train 66 struck the MBTA train 906 locomotive, both entered the gap, damaging some 400 feet of track 3.

Operations Information

editOperating Procedures—Amtrak train 66 operated on the Boston division from New Haven (MP 72.3) to Boston (MP 228.7) Amtrak also operates MBTA commuter trains in the Boston area in accordance with the operating agreement of January 1, 1987, and dispatches trains and maintains physical plants in accordance with the MBTA agreement of July 1, 1984. The CETC signal and dispatching system controls the train operations on the main tracks at Boston. The train dispatcher oversees about 220 trains daily.

Amtrak Train 66—According to the December 12, 1990, train performance sheets that Amtrak provided, Amtrak train 66 made seven scheduled and two unscheduled stops between New Haven and Boston. The two unscheduled stops required 6 minutes at MP 127 to close a baggage car door and 4 minutes at South Attleboro (MP 192) to board passengers. When the accident occurred, Amtrak train 66 was 7 minutes ahead of schedule.

Under Amtrak Air Brake and Train Handling Rules and Instructions, a locomotive engineer may use any train handling method that is within train handling guidelines for safe operation of the train. To stop a train, a locomotive engineer can use the blended dynamic brakes, the automatic airbrakes, or the locomotive independent brakes. The engineer of Amtrak train 66 stated that his method of braking was determined by the consist mix (type of cars and their different braking ratios). He said that the apprentice engineer had slowed Amtrak train 66 using the automatic airbrakes and a power braking method.

When a locomotive engineer is braking a mixed-consist[3] passenger train, according to Amtrak airbrake instructions for the power braking method, he should reduce throttle to not greater than run 4 position and then make an initial automatic airbrake reduction. Next, he should release the locomotive independent brakes and reduce throttle to no greater than run 2 position, he should not increase the throttle above that position until brake release has been initiated. The locomotive engineer should make additional reductions with the automatic airbrakes, as needed, to slow or stop. After reaching the desired speed, he should release the automatic airbrake and increase throttle. When making a stop, he should reduce throttle to idle, maintain a minimum 12-psi service reduction while stopped, and make a full application of the locomotive independent brake.

Amtrak management requires that its employees be familiar with the rules and instructions that relate to their duties. If in doubt about meaning or application, they are to ask their supervisor for an explanation. Under Amtrak rules, the locomotive engineer is responsible for observance of signals and for control and regulation of train movement. He is also responsible for instructing apprentice engineers and for ensuring that they are familiar with engine duties During the accident investigation, Amtrak officials and locomotive engineers stated that the locomotive engineer of Amtrak train 66 should have instructed the apprentice engineer to start braking the train at the Pickle Factory, a landmark structure at MP 225.7. They also said that a train operating at 100 mph could not be stopped safely if braking commenced, as was reported, at the Ruggles Street station (MP 226.2). The apprentice engineer stated that he received instruction in the power braking method in the locomotive engineer training program.

Management Oversight—Amtrak management oversees train operations through an efficiency testing program, train riding, and day-to-day supervision of operating crews. Amtrak policy requires that operating officials make at least 100 efficiency tests for operating rues compliance per month. The goal of this program is to test every operating employee on operating rules compliance every 30 days. The Amtrak efficiency testing program is on file with the FRA.

The Safety Board found that in the 11 months preceding the accident, the entire crew of Amtrak train 66 had been tested on operating rules compliance. The locomotive engineer had been tested 27 times, including 14 times for speed and 6 times for signals, and had no reported failures. Efficiency test records indicate that during the 11 months, he had been tested in the Boston area on three occasions On November 16, 1990, he underwent a running automatic airbrake test near Back Bay station. Since entering the locomotive engineer training program, the apprentice engineer had been tested five times, including twice for speed and twice for signals, and had no reported failures.

The FRA inspects Amtrak's efficiency testing records and continuously monitors Amtrak's performance for regulatory compliance. The engineer of Amtrak train 66 testified that FRA safety inspectors had accompanied him on over-the-road trips. The FRA had also observed the performance of dispatchers operating in the centralized dispatching offices No exceptions were noted.

Meteorological Information

editThe National Weather Service reported that at 8:23 a.m. on December 12, 1990, Boston had a temperature of 34°F and no rain or snow.

Medical and Toxicological Information

editAccording to hospital medical records, 278 persons were transported from the accident scene, 14 were admitted and 264 were treated for minor lacerations, contusions, and fractures and then released. Amtrak reported that after the accident, an additional 175 persons filed claims stating that they had been injured as a result of the collision.

Following the accident, in accordance with FRA regulations, Amtrak required that the train dispatcher and the 10 operating crewmembers from Amtrak train 66 and MBTA train 906 be toxicologically tested. Within 2 hours, the employees arrived at local hospitals, where blood and urine specimens could be taken.

The FRA's contract toxicological laboratory, CompuChem Laboratories in Research Triangle Park, North Carolina, received the specimens for analysis and tested them for the presence of ethanol, amphetamines, barbiturates, benzodiazepines, cannabinoids, cocaine, methaqualone, opiates, and phencyclidine. All employees tested negative.

Fire

editAt 8:24 a.m., the 911 operator notified the Boston Fire Department about the accident Upon arrival at 8:25 a.m.,[4]the fire department quickly extinguished several small fires around the locomotives Firefighters encountered small residual diesel fuel fires that caused dense smoke In about 2 hours, the firefighting and rescue operations were completed Nonetheless, the fire department maintained a detail for about 32 hours to prevent reignition while Amtrak and MBTA personnel removed debris from the accident site.

Survival Aspects

editEmergency Response—At 8:24 a.m., a 911 operator received a telephone call that a train collision-derailment had occurred at Back Bay station. The Massachusetts State Police Department, Boston Police Department, Boston EMS, Boston Fire Department, and Amtrak and MBTA police and emergency personnel were notified.

The first fire department company responded at 8:25 a.m. and reported smoke from the venting system and station concourse, as well as scores of injured persons exiting the station. The firefighters immediately ordered additional rescue equipment and ambulances to the scene. They descended into the tunnel to the collision-derailment, where, amid dense smoke, they conducted a search for injured passengers and discovered the two injured engineers from Amtrak train 66 inside locomotive 272. The firefighters radioed the incident commander for additional assistance, in all, 122 firefighters worked on the accident.

At 8:27 a.m., the MBTA police were notified of a train collision at Back Bay station. They responded with 41 officers, who assisted in evacuating passengers, controlling crowds and traffic, providing station security, escorting ambulances and emergency equipment, and directing passengers to alternative transportation.

At 8:28 a.m., the first EMS units on scene began setting up triage areas for active incident, primary triage, secondary triage, patient loading, and ambulance staging The Boston police emergency units arrived at 8:30 a.m., established an inner perimeter, and activated the mobile command post, which provided a central reporting location for the many agencies responding to the accident. In addition, the fire department and EMS communications specialists set up a portable radio repeater system. Such a system enables underground operations to communicate with surface personnel during disaster operations.

Passenger Evacuation—According to train crewmembers, the evacuation of passengers was hampered by dense smoke that obscured the lighting in the tunnel and made breathing difficult. Crewmembers with flashlights led passengers to firefighters, who in turn evacuated them from the tunnel. However, most passengers were able to exit the trains unassisted. All tunnel exhaust fans were operating at the time of the derailment, and the EMS used the three emergency tunnel exits to evacuate passengers Most passengers from MBTA train 906 used the main exit from platform 2 Because the tunnel was blocked by the derailed locomotives, most passengers from Amtrak train 66 used the other tunnel emergency exit. Buses and ambulances transported the injured to local hospitals and the uninjured to South Station.

MBTA Train 906 Crew—Just after impact, the conductor, who had been in control car 1614, assisted passengers off the car onto the platform one assistant conductor, who was standing in the vestibule of the third car (302) at impact, heard a sound like an explosion from the rear of the train. He was hit by a piece of metal and thrown onto the platform. He proceeded through dense smoke to the platform exit doors and directed passengers up the stairs A second assistant conductor, who had been announcing the coming station stop, next remembered being on a stretcher en route to a hospital. The third assistant conductor was stationed at the door making an announcement; he next remembered being in the hospital.

Amtrak Train 66 Crew.—The two assistant conductors and the deadhead conductor stated that they were in the fifth car, coach car 21248, at impact. The coach tipped at an angle to the left toward track 1 During the accident sequence, both coach doors were crushed and jammed shut. As they opened emergency windows to evacuate passengers, the coach filled with smoke. They assisted passengers through dense smoke along the catwalk and met emergency personnel, who guided them to the station platform.

At impact, the conductor was in dining car 20238. He was thrown forward, striking his head on a counter. The one passenger in this car was uninjured. The conductor moved through dining car 20238 toward coach car 4702 and spoke with the lead service attendant, who assured him that the passengers in coach car 4702 did not need immediate medical attention. The conductor then proceeded to coach car 21070, which had tipped on its side, and pulled out emergency windows to evacuate passengers. When the fire department arrived, the conductor and the two injured engineers were evacuated and transported to a hospital.

The lead service attendant, who was sitting in dining car 20238, was thrown into the opposite seat and sustained multiple contusions. He proceeded to coach car 4702; through a small opening between dining car 20238 and coach car 4702, he assisted passengers off the train. He stated that the rescue activities were very "organized and efficient".

The sleeper car attendant said that he was seated inside sleeper car 2994 when the impact pushed him onto his knees. He sustained a contusion to his right knee. After confirming that the passengers on the sleeper car were uninjured, he retrieved his flashlight and proceeded to the forward coach cars. With the help of firefighters, he assisted and guided passengers off the train. Because of the dense smoke inside the tunnel, he left the accident site about 15 minutes later. He stated that his training in emergency and evacuation procedures proved valuable during the accident evacuation.

MBTA Train 906 Exits—Control car 1614 (lead car) and passenger cars 1525, 302, 326, 347, and 333 did not derail following the collision. The passengers exited from the doors at both ends of the cars. All wheels on passenger car 315 had derailed, and the car sustained massive damage. It remained upright against the stairwell housing between tracks 1 and 3. All emergency windows were removed. The west end of the car was crushed and the exit door blocked; at the east end of the car, the exit door to the platform was opened. The unoccupied locomotive 1073 was destroyed. (See figure 4)

Amtrak Train 66 Exits—The collision destroyed the two-unit locomotive (272 and 366) of Amtrak train 66. However, the locomotive engineer's side of the cab was intact on unit 272, and both the locomotive engineer and apprentice engineer were evacuated from that side. (See figure 5) The head end material handling car (1551) and the baggage car (1217) held no passengers or crew. Coach car 21248 derailed and was leaning at a 40-degree angle. The exit doors were jammed shut at one end and destroyed at the other end. The emergency windows on the sides offered the only possible exits. (See figure 6) Coach car 21190 derailed onto track 1 and was leaning at a 20-degree angle. Emergency windows had been removed and were inside the coach. The vestibule door was hanging open at one end; the other end was destroyed. Coach car 21070 was upright with all wheels derailed. Emergency windows had been removed and were inside the coach. The stairway at one end was slightly damaged, and the stairway at the other end was destroyed. One end of dining car 20238 derailed, and the exterior of the car sustained minor damage. Coach car 4702 and sleeper car 2994 did not derail, and the exteriors were not visibly damaged. The baggage car (1188) and the material handling car (1552), which held no passengers or crew, sustained no damage.

Emergency Preparedness—The city of Boston has a Comprehensive Emergency Management Plan (CEMP) that combines the four phases of emergency management mitigation, preparedness, response, and recovery. Last updated in September 1989, the CEMP was activated for this accident.

The fire department has an ongoing training program in cooperation with the MBTA and the local railroads. It periodically conducts drills with MBTA safety personnel in various stations to familiarize the first alarm and rescue companies with the fire safety equipment and facilities. During the drills, fire department personnel inspect the standpipe system, the smoke control system, the elevators and ramps for the handicapped, and other physical features.

The city of Boston conducts disaster drills at 6-month intervals, and the participants include personnel from the police and fire departments, the civil defense agency, and hospital and rescue ambulance services. The June 1990 drill, in cooperation with the MBTA, featured a mock hazardous materials incident and included exercises in extricating passengers from trains, trolleys, and buses.

===Tests and Research===

Speed Indicator Test—On December 13, 1990, Safety Board investigators tested the speed indicator from locomotive 272 for proper calibration. Test results showed that the speed indicator displayed 105 mph at a true speed of 110 mph. According to FRA requirements in 49 Code of Federal Regulations (CFR) Part 229, locomotive speed indicators must be accurate within +/- 5 mph at speeds above 30 mph.

Maintenance Records—Safety Board investigators reviewed the maintenance and repair records for locomotive units 272 and 366 on Amtrak train 66 for the 30 days before the accident. On December 7, the automatic airbrake valve on locomotive 272 was replaced. A locomotive engineer reported on December 10 that a minimum 6- to 8-psi reduction actually resulted in a 10-psi reduction, this condition persisted on December 12, the day of the accident. A brake test that day revealed that locomotive 366's equalizing reservoir leaked.

Locomotive Airbrake Valve Tests—On December 14, Safety Board investigators tested the automatic airbrake valves on the Amtrak train 66 locomotive using the test rack at the MBTA air room in Boston. The test rack was verified to ensure that it functioned properly. In addition, they tested the service brake valves from locomotive units 272 and 366. (The independent brake valve, which controls only the locomotive brakes, allows the locomotive engineer to release those brakes when all train brakes are applied using the automatic airbrake valve.) When tested, the automatic airbrake valve functioned as designed, air pressure on both service brake valves was irregular. The investigators also used an MBTA F40PH locomotive to test the automatic airbrake and service brake valves from locomotive 272. Both functioned in the same manner as they had on the test rack.

The valves were again tested at the Westinghouse Air Brake Company in Wilmerding, Pennsylvania, on January 23, 1991. Test results from the service brake valves on locomotives 272 and 366 showed that the locomotive brakes were not applying as designed and that the independent braking power of both locomotive brakes was reduced. Inspection revealed that compressor oil or grease had built up in the valves and that the rubber diaphragm from locomotive 366's service brake valve had an irregular surface, including surface cracks. The automatic airbrake valve from locomotive 272 was tested, and it functioned as designed.

Event Recorder Information—Locomotive 1073 on MBTA train 906 was equipped with a Barco paper tape speed recorder that was destroyed in the accident. The tape from the Barco paper tape speed recorder on control car 1614 indicated that MBTA train 906 was traveling about 15 mph when the collision occurred.

The Barco paper tape speed recorder on locomotive 272 (Amtrak train 66) was damaged in the accident. The tape was torn and had no speed trace on it Amtrak locomotive 366 was equipped with a Pulse 48-hour magnetic tape event recorder, from which the data pack was recovered. After the accident, at 10:05 a.m., the Amtrak assistant transportation superintendent had a readout done on the Pulse readout machine at South Station. Amtrak reported that it transcribed two identical strip charts of the data and kept one copy. Amtrak also advised the Safety Board that for undetermined reasons, some data had not shown on the strip charts. At 6 p.m. Safety Board investigators received the other strip chart and the Pulse data pack from Amtrak locomotive 366 and the Barco speed recorder paper tapes from Amtrak locomotive 272, MBTA locomotive 1073, and MBTA control car 1614.

On December 13, Amtrak asked the Safety Board to make an identical readout of the Pulse data pack. The Safety Board accompanied Amtrak personnel to South Station, where the Pulse data pack was again read out on Amtrak's Pulse readout machine. This readout did not show accident data either. The Pulse data pack was sent to the Safety Board laboratory in Washington, D.C., where the accident data were partially recovered.

Event Recorder Tests—The Safety Board laboratory received the Pulse data pack from Amtrak locomotive 366 for readout and evaluation on December 13. The laboratory's Pulse readout machine generated a strip chart of the data recovered. Data from the event recorder, which recorded information about every 5 3/4 seconds, showed no signs of accident damage. Safety Board engineers found an electronic end-of-tape mark[5] on the magnetic tape that prevented strip chart output of data from Route 128 to just beyond the accident. Data before the end-of-tape mark indicated that the train had operated at speeds up to 110 mph between Kingston and Providence and between South Attleboro and Route 128 (See figure 7 for the Pulse magnetic tape event recorder strip chart.)

An end-of-tape mark normally indicates that all 48 hours of the tape data have been reproduced on the strip chart. Pulse designed two safeguards into the event recorder system components to prevent inadvertent placement of an end-of-tape mark over the most recently recorded data. The first safeguard is a ratchet mechanism inside the Pulse data pack that prevents rotation of the tape spool in the direction opposite to the recording direction. The second safeguard is the manner in which the Pulse readout machine creates an end-of-tape mark. The readout machine advances the tape in the recording direction away from the most recently recorded data, creates the end-of-tape mark, and then starts the transcription of data to the strip chart.

From tests, Safety Board investigators determined that the Pulse 48-hour magnetic tape event recorder and its data pack from Amtrak locomotive 366, as well as the Pulse readout machine at South Station, functioned as designed. Both the Pulse data pack's ratchet mechanism and the Pulse readout machine's end-of-tape mark feature also functioned as designed.

Safety Board laboratory engineers found that the end-of-tape mark on the magnetic tape was 13.6 minutes long, 2.2 minutes longer than the minimum 11.4-minute end-of-tape mark that usually exists after a readout. Also, this end-of-tape mark began at Route 128 (MP 217.3) and ended just beyond the accident (MP 227.45) data. Given the safeguards designed into the Pulse event recorder system components, the end-of-tape mark over the most recently recorded data should not have occurred.

Given that no failure of the ratchet mechanism on the end-of-tape mark feature could be found, Safety Board laboratory engineers attempted to determine

how an end-of-tape mark could have appeared on the accident magnetic tape. The data pack could have been opened, the tape spool lifted up and away from the ratchet mechanism, the tape wound in the direction of the most recently recorded data, and the end-of-tape mark placed on the tape. Or, the initial readout could have been made without an end-of-tape mark and the data pack could have been pulled out of the readout machine just before Route 128 (MP 217.3) data. Amtrak officials stated that they do not believe either action was ever taken.

Because an end-of-tape mark prevents a strip chart output of data, laboratory engineers extracted the data manually. During the initial readout generated on the laboratory's Pulse readout machine, they had copied the data to 1/4-inch magnetic tape, reel-to-reel. Using the reel-to-reel copy, they performed subsequent readouts and evaluations. They extracted the remaining raw data from the end-of-tape mark area and converted it to engineering units. The conversions yielded information on speed, distance travelled, and brake and throttle positions. Since recorded elapsed time data were not recoverable, they derived the elapsed time from the known timing on the event recorder data.

The recovered Pulse event recorder data indicate that from the last stop at Route 128, Amtrak train 66 accelerated at throttle run 8 position with brakes released to a maximum speed of 109 mph, which was achieved approximately 5,400 feet before the last recorded data at MP 227.45. A single full-service brake pressure reduction of 32 psi was recorded, it occurred 4,940 to 4,024 feet before the last recorded data. A single throttle position change from maximum run 8 position to idle was recorded 4,024 to 3,127 feet before the last recorded data. Brake pressure and throttle position values remained constant throughout the remaining recorded data. The last recorded speed was 76 mph, and no emergency brake application was recorded that would indicate that the pneumatic control switch (PCS) was open. When the PCS has been opened by an emergency brake application, the Pulse event recorder senses it electronically. The brake and throttle data are sampled and recorded about every 5 3/4 seconds. Therefore, if the PCS was opened within the last 5 3/4 seconds, the emergency brakes may have been set and not recorded. (For event recorder data recovered from Amtrak train 66, see figure 8.)

Stopping Distance Simulation Tests—On December 21, 1990, a Safety Board investigation team conducted stopping distance tests between Kingston (MP 158.1) and Davisville (MP 168.3) using a train consist similar to that of Amtrak train 66 on the date of the accident. The test train carried no passengers. To simulate the stopping distance, the investigators used information recovered from the Pulse event recorder and provided during witness testimony. When stopping the train from speeds[6] of 103 to 108 mph, the automatic airbrakes, with the independent brake released, were applied 4,950 to 4,400 feet [7] before a mark that indicated the POD. Test results showed that Amtrak train 66 would have been moving 76 to 80 mph at the POD.

Braking Speed Simulation Tests—On February 20 and 21, 1991, the Safety Board conducted 11 computer simulated braking tests on a train dynamics analyzer at Freight Master, Inc., in Fort Worth, Texas. The track profile of the accident area and the physical characteristics of Amtrak train 66 consist were programmed into the simulator.

Additional conditions for each test were determined from the Pulse event recorder data and the reported operating procedures of the train's locomotive crew. According to the locomotive engineer and the recovered event recorder data, the apprentice engineer began braking Amtrak train 66 at the west end of the Ruggles Street platform (about 4,950 feet before the POD). Event recorder data show a maximum recorded speed of 109 mph approaching Ruggles Street.

In the simulator tests, the Safety Board used information developed from the manufacturer's braking graphs,[8] the Pulse event recorder data, and the described braking method. These simulated braking tests show that moving at 109 mph, Amtrak train 66 would not have slowed to 59 mph (approximate turnover speed) in 4,950 feet using the power braking method, unless the brakes had been applied in emergency at the Ruggles Street station platform. In addition, the train would have required at least 4,950 feet to reduce speed to 32 mph in emergency braking with the locomotive brakes fully applied. The turnover speed would have been exceeded in any full service braking sequence from 109 mph that the locomotive crew could have used from Ruggles Street. According to the manufacturer's braking graphs, in full service braking at 109 mph, the stopping distance would have been 9,010 feet.

Amtrak's Postaccident Actions

editDuring the Safety Board's on-scene accident investigation, Amtrak installed an advance warning sign for the 30-mph speed restriction that is in effect between MP 227 and MP 228.3. The sign was positioned near the Pickle Factory (MP 225.7) Amtrak has also installed advance warning signs for speed reduction at locations on the Northeast Corridor that have similar slowing conditions.

In addition, Amtrak reports that it has altered the circuitry of the wayside automatic block signal at MP 226.2 (Ruggles), approaching Back Bay station, to display an "approach medium" signal aspect, indicating that the train is to proceed to the next signal at medium track speed (not exceeding 30 mph.) If a locomotive engineer fails to initiate automatic airbrake application after passing this signal, the automatic speed control system will cause a brake application. Amtrak reports that it has altered the wayside automatic block signals at five other locations on the Northeast Corridor that have similar speed reduction conditions.

Amtrak has also established a postaccident event recorder procedure that requires the locomotive event recorder to remain sealed until the Safety Board or the FRA arrive on scene to witness the removal of tapes.

Locomotive Engineer Training

editSources of Information—The following information is based on statements or testimony taken from three Amtrak engineers, two recently promoted graduates of the Amtrak Locomotive Engineer Training Program, two apprentice engineers, the system general road foreman, the manager of engineer training, the director of operating rules and procedures, the coordinator for apprentices for the Boston division, the Amtrak general manager of transportation, and the Amtrak executive vice president.

Program Organization—Amtrak inaugurated its current engineer training program for passenger service in April 1987. It was developed exclusively by in-house staff. The system general road foreman testified that at the time of the accident, Amtrak had offered the training to 13 classes, including the class attended by the Amtrak train 66 apprentice engineer, 141 apprentice engineers have participated in the program. Of the 119 apprentices who took part in the first 12 classes, 101 became qualified engineers. Selection of participants was based on employee eligibility under company seniority rules and stipulations in the Brotherhood of Locomotive Engineers (BLE) union contract.

As described by the manager of engineer training, the training program consists of four phases classroom instruction at the engineer training school, qualification on the physical characteristics[9] of the apprentice engineers' territories, OJT, and instruction using the locomotive simulator at the IIT. He also stated that the simulator is used to evaluate apprentice engineers' performance after the OJT is completed. According to the manager of engineer training, the order in which the four phases are offered varies, depending on the needs of the class being trained, and the physical characteristics and OJT phases are sometimes combined. The "Locomotive Engineer Training Program Master Sheet" (see appendix C) distributed to apprentices at the engineer training school corresponds with his description of the program.

The system general road foreman also stated that the program consists of four phases. According to his description, Amtrak combined the physical characteristics training and OJT into a single phase, he identified the fourth phase as the "certification" of apprentice engineers on the locomotive simulator. He indicated that the time frame for the complete program ranges from 6 months to more than 1 year, depending on the needs of the individual. One recently trained engineer stated that he had required 17 months to become certified.

Classroom Training Phase—The classroom phase, or engineer's training school, for the program has been offered in Chicago near the IIT simulator facility and in Wilmington, Delaware, adjacent to the locomotive and car shops. According to the system general road foreman, Amtrak uses the Chicago facility to instruct engineers from divisions not on the East Coast; those divisions do not need training on electric locomotives. The Wilmington location is used for trainees who are to be assigned to the Northeast Corridor after they are promoted to engineer. The manager of engineer training stated that the time allotted for classroom courses taught in Chicago is 5 weeks. Up to 9 weeks is allotted for the classroom courses at the Wilmington facility, depending on whether apprentice engineers are given an additional 2 weeks of instruction for electric locomotives and 2 weeks of special instruction on Northeast Operating Rules Advisory Committee (NORAC) rules. He said that staff from the Amtrak rules department teach the NORAC rules in Wilmington; trainees assigned to the Chicago classes receive Amtrak rules instruction in their home division either before or after the engineers' classes. The manager of engineer training explained that one of the advantages of the Wilmington facility is that the classrooms are adjacent to the shops, he estimated that 15 to 20 percent of the class time there is hands-on teaching.

The apprentice engineers and recently trained engineers who had attended the classroom training made positive comments about the course, the instructors, and the evaluations they received. They said that the school puts a great deal of pressure on them to learn at a fast pace. One apprentice engineer recalled 14 to 15 quizzes in his class that required a score of 85 percent to pass. Class size was reportedly 5 to 12 members.

Physical Characteristics Familiarization—The training program requires qualification of apprentices on the significant characteristics of the territories over which they will operate. Familiarization is accomplished by having apprentices ride locomotives regularly on these routes, after which a rules examiner conducts an oral examination. If the apprentices pass, they are "qualified" on those territories.

The coordinator for the Boston class stated that qualification of apprentice engineers on physical characteristics before they receive their classroom instruction is not essential. The system general road foreman testified that apprentices must qualify on physical characteristics before they are permitted to run a locomotive. The instructing engineers for apprentice OJT stated that trainees with a valid permit (head end pass) to ride the locomotive operate the train on the basis of the trainees' acquired skills. No engineers or apprentice engineers identified any documentation provided to show that they had passed qualification testing on the physical characteristics of their territories, and one apprentice said he had operated trains before being qualified. The apprentice engineer on Amtrak train 66 stated that he completed his physical characteristics qualification before attending the class.

One apprentice engineer questioned the time he was allotted for qualifying on physical characteristics and for learning train operation. He said that he had expected 8 months to complete his training program after the class and expressed concern to the system general road foreman that he would need 12 months. The apprentice also told Safety Board investigators that the time Amtrak allotted for learning the routes did not correspond to their difficulty. As an example, he recalled being allowed 8 weeks to learn the Boston to Springfield route and 14 days to learn the more difficult New Haven to Hartford line. He described the learning process for qualifying on the physical characteristics as studying, memorizing, and passing a test and cautioned that"it would be hard" for him to say that he actually knew the characteristics from these training procedures. The accident apprentice engineer's training class was the first in which successful completion of examinations on physical characteristics was required.

The system general road foreman testified that he was aware of the concerns of apprentices and recently trained engineers about the program. He also said that he was "comfortable with" the times allocated for learning the physical characteristics. The coordinator for the Boston classes stated that learning the physical characteristics in the training program is to be accomplished within a fixed period of time. He also thought apprentices should have more time than has been allotted to learn their territories.

Simulator Training Phase—Amtrak leases time on the train simulator at IIT for both instruction and evaluation purposes. The manager of engineer training said that the current version of the training program allots 4 days for simulator training, which is to be completed before apprentices begin their OJT. The simulator instruction is for "superliner" equipment and power braking. The manager of engineer training identified three "experiences" provided to apprentices during the simulator instruction phase, rules compliance, operating efficiency, and train handling. He stated that after each apprentice completes his instruction, a member of the simulator operations staff critiques his performance.

Although one apprentice engineer said that the simulator is an "excellenttool," other engineers trained under the program told Safety Board investigators that their instruction on the simulator was not applicable to their equipment or territories. One recently trained engineer stated that he did not find the simulator part of the training program useful, and he did not know why the section of railroad presented for his simulation was a stretch of territory in Utica, New York, that he never expected to work on Another Amtrak apprentice engineer recalled being given a section of Burlington Northern track during his simulation. The manager of engineer training explained that the sections of railroad used for the simulator are intended to be "generic."

On-the-Job Training Phase—The purpose of the OJT phase is to build operating skills through experience on locomotives, according to the system general road foreman. Apprentices in this training phase ride with regular engineers and operate the train under the qualified engineer's guidance. The system general road foreman testified that OJT is the most critical training in the program. He also stated that apprentices are assigned to the engineers for OJT based on the personalities involved and that Amtrak supervisors monitor OJT. He added that he usually observes trainees himself during this phase.

One engineer who had instructed apprentices for OJT since 1988 said that apprentices "just show up" and request that they be permitted to ride for the trip. Another engineer stated that Amtrak management sometimes asks engineers whether they will consent to having an apprentice ride with them. He noted that some engineers have declined. All engineers who were questioned said that no riding assignments were made in advance for recent classes. Apprentices usually asked to ride with them when the engineers were preparing for their trip and boarded the train after showing the engineer their head end pass. One recently trained engineer stated that he had been assigned to engineers for some of his OJT. Another engineer trained under the program said he may have worked with 20 different engineers while on his OJT, and one other recently trained engineer stated that an apprentice had already ridden with him for OJT.

Apprentice engineers in the current class told Safety Board investigators that they were selecting their own instructing engineers. They said they frequently based their choice on two factors, the convenience of the trip in terms of schedule and destination and the engineers' willingness to allow the apprentices to operate the train.

The system general road foreman testified that Amtrak requires coordinators from its transportation department to observe the apprentices weekly during their OJT. In addition, both the coordinators and the instructing engineers are to evaluate the apprentices' progress in writing. He also said that apprentices give instructing engineers a performance evaluation form to complete after the trip (See appendix D) According to one apprentice engineer, the purpose of any forms he was given was solely to verify that he had ridden the train.

No apprentice or recently trained engineer indicated to Safety Board investigators that the system general road foreman or the class coordinator had ridden with them to observe their performance. One instructing engineer recalled that a training class coordinator had asked him how well individual apprentices were doing and whether a particular apprentice was ready. A recently trained engineer said that he was not aware of any evaluation of his performance other than this questioning of one of his instructing engineers. No engineer questioned by Safety Board investigators said he had received any training or preparation for his instructing duties.

The manager of engineer training said that expected completion times for OJT ranged from 3 to 6 months, depending on the abilities of the students in the class. The coordinator for the Boston classes stated that OJT was limited to 3 months, but he recalled giving one apprentice more than 1 year, another 11 months, and a third 10 months. He also stated he himself had decided when apprentices were ready to leave the OJT phase in the last two classes. According to the manager of engineer training, the school does not participate in the advancement of engineers after they leave the classroom phase except for scheduling the simulator, and the school staff does not follow up during OJT.

Final Evaluation of Apprentices—The system general road foreman said that the final evaluation or certification of apprentices before they become engineers is done on the IIT simulator. An Amtrak official oversees this procedure, which is conducted by IIT staff. When an apprentice has passed his certification examination on the simulator, the Amtrak engineer training school is notified. Officials at the school in turn notify the class coordinators in the transportation department. The apprentice is then considered a qualified engineer and can "mark up" for service in his division. If the apprentice does not pass this examination, he returns to OJT and arrangements are made for retesting. In the most recent class, some apprentices took their certification examination on the simulator before they had completed their OJT. Safety Board investigators were told that currently, if apprentice engineers fail the training program, they are not permitted to return to their previous jobs and are terminated by Amtrak. Apprentices stated that the possibility of losing their jobs put them under great pressure.

Program Administration—The system general road foreman testified that the engineer training program is one of his responsibilities but also stated that his relationship with program staff and supervisors is advisory. He said that he did not have any knowledge of Amtrak training for any crafts other than the engineer training program.

The system general road foreman identified a line of authority for the engineer training program from a senior director of training in the human resources department in Washington to a director of training in Chicago. He said that the manager of engineer training at the Wilmington facility is the director of the engineer training school and reports to the Chicago-based director of training.

According to the manager of engineer training, the human resources department has administrative accountability for the school. This department is also responsible for processing apprentice engineers' records pertaining to physical characteristics qualification, completion of OJT, and simulator instruction. Simulator time for final evaluation and certification at the IIT facility is scheduled through the human resources department. The manager of engineer training explained that the system general road foreman has accountability for trainees in the OJT phase of the program and that the transportation department establishes criteria to determine when an apprentice is eligible to "mark up" as an engineer.

The manager of engineer training indicated that the transportation department is responsible for the administration, follow up, and monitoring of trainees in OJT. A system transportation manager from the transportation department is assigned to coordinate each class.

Development and Evolution of the Program—According to the system general road foreman, Amtrak has changed the program primarily to adapt the training to the makeup of individual classes. The manager of engineer training stated that the engineer training school has never been evaluate to determine how well it is performing its mission. The general manager of transportation testified that he anticipates program changes, including weekly supervisory rides with apprentice engineers and selection and approval of instructing engineers before they participate in the program. He also said Amtrak management was reviewing the engineer training program at the time that the Safety Board was taking depositions for the accident. Safety Board investigators later learned from Amtrak's executive vice president that Amtrak initiated the management review primarily to determine whether the engineer training program complies with FRA locomotive engineer qualification requirements in 49 CFR Part 240.

Engineers' and Apprentice Engineers' Concerns—A recently trained engineer stated that Amtrak should allot more time for OJT. He explained that he would have benefited from additional training beyond the 17 months he had received. He added that he thought he was ready to begin working by himself but that 3 or 4 more months of training would have been useful.

One apprentice engineer contrasted the duration of the engineer training program with the time allotted to complete his apprenticeship as an Amtrak electrician. He recalled that the latter included 16 weeks of classes, together with a 3-year apprenticeship, and that during his apprenticeship he received 8 additional hours of classroom instruction a month.

FRA Engineer Certification—On December 11, 1989, the FRA published a notice of proposed rulemaking (NPRM) to address the requirements for qualification of locomotive engineers. The FRA proposed that railroads consider the following five criteria: vision and hearing acuity; sufficient knowledge of operating rules, as demonstrated by passing a written examination; sufficient train operation skills, as demonstrated by passing a performance skills test, eligibility, as demonstrated by the individual's railroad employee and motor vehicle driver record, and familiarity with the physical characteristics of the routes on which the individual would operate. In addition, the NPRM identified minimum hour requirements for instructional activities. Minimum classroom training time for experienced railroad employees and for newly hired employees was to be 158 hours and 198 hours, respectively. A qualified locomotive engineer instructor was to provide a minimum of 480 hours of OJT, including at least 240 hours at the locomotive controls. Simulator training could be substituted for part of this OJT time.

Published on June 19, 1991, the final rule for locomotive engineer qualification in 49 CFR Part 240 became effective on September 17, 1991. The rule requires railroads to have a formal process for evaluating prospective locomotive engineers and to determine their train operation competency before permitting them to operate equipment. Under the regulations, railroads must also conform to FRA-approved training programs for prospective locomotive engineer candidates, employ standard methods to identify qualified engineers, and monitor engineers' performance. If a railroad hires qualified persons as locomotive engineers or employs another entity to conduct training on its behalf, that railroad may elect not to have a training program.

In response to industry comments, the final rule gives railroads greater discretion in designing their qualification programs for initial and continuing locomotive engineer training. The rule specifies minimum subject matter requirements and learning activities for skill performance and familiarity with physical characteristics of the territory, but it does not prescribe minimum hour requirements for instruction activities or procedures to conduct training and evaluation processes.

Event Recorder Regulations—The Rail Safety Improvement Act of 1988 directed that within 18 months of its enactment on June 22, 1988, the Secretary of Transportation was to issue such rules, regulations, standards, and orders, as may be necessary to enhance safety, that require trains to be equipped with event recorders.

The FRA issued an NPRM on June 19, 1991, for the drafting of event recorder regulations under 49 CFR Part 229. In September and October 1991, public hearings were conducted to receive comments about the proposed regulations. On October 30, 1991, the Safety Board provided comments generally supporting the FRA-proposed rulemaking, but asking that event recorders be required on all trains operating outside yard limits (rather than exempting freight trains with fewer than 50 cars or traveling at less than 30 mph) The Safety Board also requested that the FRA begin developing standards for a crash- and fire-resistant event recorder with a standard data recording format and for postaccident event recorder handling.

ANALYSIS

General

editSafety Board investigators conducted interviews, examined dispatcher records, and made track and signal inspections and tests. On the basis of this information, the operation of MBTA train 906, the CETC system, and the track have been eliminated as causal factors. The MBTA train 906 crew was physically fit for duty. In addition, neither the weather nor alcohol or illicit drug use were contributory factors in this accident. Amtrak train 66 operated on schedule from Washington to New Haven with no defects noted. At New Haven, both the operating crew and the locomotive power of Amtrak train 66 changed. The operating crew was well rested and physically fit for duty. No exceptions were taken to the ground inspection or airbrake testing of the train. Safety Board tests of the brake system on Amtrak train 66 revealed no defects that contributed to the accident.

Factors that will be discussed include train operations and speed limits, locomotive engineer training and FRA qualification, and locomotive event recorders.

The Accident

editOn the trip from New Haven, Amtrak train 66 made six scheduled station stops, a stop to close the baggage car door, and one unscheduled station stop. The apprentice engineer made the stops under the supervision of the locomotive engineer. The traincrew noted no exceptions to the operation of the train during the trip. Examination of the event recorder tapes revealed that after both unscheduled stops, Amtrak train 66 exceeded the 100-mph speed limit and made up time lost on the schedule.

On the trip, the apprentice engineer employed the power braking method that was taught in the locomotive engineer training program. This braking method, described in Amtrak's instructions on operations and train handling, is preferred for a mixed-equipment consist and provides a smoother stop for the passengers. It entails stopping or slowing the train by applying the automatic airbrakes on all cars, while keeping the locomotive under power and the locomotive independent brakes released. The objective is to first minimize the train slack by applying the brakes on all cars. The train is then slowed to the desired speed by reducing locomotive power and making subsequent small brakepipe applications.

Initiating the service reductions sufficiently in advance of the stopping point is absolutely necessary to allow enough time to adjust the speed. Stopping a train from about 100 mph using the power braking method requires about 3,000 feet more than braking the train using automatic airbrakes with locomotive independent brakes or blended dynamic brakes. Because of the additional distance required for power braking, the locomotive engineer's familiarity with the braking points and his communication of that information to the apprentice are very important for proper brake applications

According to the locomotive engineer, he instructed the apprentice engineer to initiate the braking sequence for Back Bay station near the west end of the Ruggles Street station platform (MP 226.2) However, the event recorder data indicate that braking was not initiated at that location. Even if the instructions had been issued there, they would have been issued too late to slow the train to comply with the 30-mph speed restriction at MP 227. The locomotive engineer stated that a 10-to 12-psi first-service reduction was made, but the train failed to slow as much as usual. The event recorder data do not show that a 10- to 12-psi reduction was made.

The locomotive engineer said he next instructed the apprentice engineer to apply a 32-psi full-service reduction, and the apprentice complied. The locomotive engineer stated that when the train did not slow sufficiently, he made an emergency application of the automatic airbrakes near the tunnel entrance (MP 227). However, sand[10] found on the track 480 feet before the POD indicates that an emergency brake application was probably made at this point and not at MP 227 as reported. At 76 mph, the emergency brake application would have occurred no more than 4 seconds before the POD.

The event recorder data show only one full-service brake application. However, because the event recorder samples data every 5 3/4 seconds and because almost 5 3/4 seconds had elapsed when the event recorder stopped recording, the emergency brake could have been applied and not have been recorded. If the train had been placed in emergency braking at MP 227, the application would have been recorded because the train would have required more than 5 3/4 seconds to travel from MP 227 to the POD. The Safety Board concludes that the claimed 10-to 12-psi first-service reduction was not made and that the emergency brake application was made about 480 feet before the POD, not at MP 227 as described by the locomotive crew.

Amtrak train 66 continued into the curve near MP 227.4. The Safety Board concludes, based on event recorder data, that the speed of Amtrak train 66 was about 76 mph as it entered the 30-mph speed restriction for the curve into Back Bay station. Amtrak train 66 derailed and struck locomotive 1073 on the rear of MBTA train 906, which was approaching the station to make a stop on track 1.

Advance Warning Devices—The advance warning sign that Amtrak installed and the signal circuitry changes to the automatic wayside block signal at MP 226.2 that Amtrak made following the accident provide a method of warning traincrews that they are about to enter the curve to Back Bay station, which has a 30-mph speed restriction. The warning sign is a visual reminder to the crew of the approaching speed restriction, and the automatic speed control registers the track circuit code for "approach medium." If the engineer fails to make a brake application after passing signal 226.2, the signal indication change will audibly warn the traincrew to begin slowing the train, using a brake application, and to proceed at medium speed (not exceeding 30 mph) to the next signal. The train will automatically be brought to a stop if the crew fails to take action to reduce speed. When both warnings are acknowledged, the traincrew should then be aware of the speed restriction at MP 227 and slow the train accordingly.

Before the accident, the signal system approaching Back Bay station was not intended to restrict the movement of trains to less than the maximum authorized track speed of 100 mph unless the movement of other trains would interfere with the unrestricted movement or the signal system failed. The 30-mph speed restriction for trains entering Back Bay station is only referenced in the special instructions of Amtrak's timetable as an operating rule restriction. Amtrak relied completely on the engineer's ability to be ever cognizant of his location and to relate the special instructions, if any, to that location. Thus, previous procedures did not provide redundancy in case of human failure. The Safety Board is concerned that Amtrak permitted passenger trains, especially one being operated by an apprentice engineer, to operate at speeds to 100 mph in an area approaching Back Bay station without considering or providing redundancy for the consequences of human failure. The Safety Board believes that Amtrak did not recognize the potential problems for the slowing condition entering Back Bay station and the possible consequences of a human failure to comply with the rules. Had Amtrak taken the action before the accident that it took afterward, the accident may have been prevented.

Brake Inspections and Tests—Before the accident, Amtrak train 66 underwent ground inspections and airbrake tests in Washington, D.C, and New Haven. No exceptions were noted with the equipment or brakes. The crew operated the train from New Haven and reported no train defects or brake problems before the claimed brake problems.