TUNNEL, a subterranean or subaqueous way, constructed for purposes of passage. In mining, the term is often applied to horizontal excavations, especially to such as are known by the designations gangway, heading, drift, and adit, used as underground roads or for the passage of water. (See Adit.) Herodotus mentions a tunnel in the island of Samos, cut through a mountain 150 orygia (900 ft.) high. Its length was seven stadia (4,247 ft.), and its cross section 8 ft. high by 8 ft. wide. In Bœotia a tunnel was constructed for the drainage of Lake Copais. When Cæsar arrived at Alexandria, he found the city almost hollow underneath from the numerous aqueducts; every private dwelling had its reservoir, supplied by subterranean conduits from the Nile. The aqueducts of the ancient Romans, and of the Peruvians and Mexicans, included remarkable tunnels. (See Aqueduct.) Among the many Roman aqueducts on which tunnels were built were the Aqua Claudia, of which 36½ m. passed underground; the Aqua Appia, built in 312 B. C., 11,190 Roman paces in length, 11,130 being underground and arched; and the Aqua Virgo, 14,105 paces long, 12,865 underground. A tunnel was begun in 398 B. C. to tap Lake Albanus, at the instance, Livy tells us, of the oracle of Delphi. It was 6,000 ft. long, 6 ft. high, and 3½ ft. wide. Fifty shafts were sunk on its line, and the work was finished within one year, though it was driven through the hardest lava. A similar work of greater magnitude was undertaken to connect Lake Fucinus (now Celano) with the river Liris (now Garigliano); 30,000 men were employed on it for ten years, and it was finished at a vast expense A. D. 52. A minute account of the modern clearing out of this work by the Neapolitan government may be found in “Blackwood's Edinburgh Magazine,” vol. xxxviii., p. 657. The accuracy of the surveying in these works is astonishing when we consider the rudeness of the instruments. Among those used in levelling by the Romans were the libra aquaria and dioptra, of which we have no clear description. The chorobates seems to have been preferred. It consisted simply of a rod or plank about 20 ft. long, mounted on two legs, at its extremities, of equal length. The rods or legs were secured by diagonal braces, on which were marked correctly vertical lines. A plumb line attached at each extremity, and passing over these diagonal braces, indicated whether the instrument was level. When the wind prevented the plumb bobs from remaining stationary, a channel in the upper edge of the horizontal rod was filled with water, and if the water touched equally both extremities the level was supposed to be correct; and then the observation of the descent or elevation of the ground was made with accuracy.

|

|

| Fig. 1. | Fig. 2. |

—Tunnelling might be classed under four general heads:

1, ancient tunnelling, to which we have just

referred; 2, modern tunnelling through soft

ground (clay deposit, &c.) and loose rock,

requiring arching; 3, modern tunnelling through

solid rock before the introduction of machinery;

4, modern tunnelling through solid rock

with the aid of machinery. The art of tunnelling

at the present day constitutes a profession

in itself, now developments succeeding each

other with great rapidity. Figs. 1 and 2 show

cross sections that may bo adopted in tunnelling:

fig. 1 through rock tenacious enough to

require no artificial support; fig. 2 where arching

may be found necessary. These examples

are from plans adopted in the construction of

the Musconetcong tunnel, New Jersey, on the

Lehigh Valley railroad extension, finished in

1875.—Tunnelling through Soft Ground.

Under the designation “soft ground,” technically

so called, the miner includes all such material

as clay, earth deposit, &c., which, if tunnelled

through, requires a temporary timber arch to

hold it in place, until the permanent brick or

stone arching is built. Loose rock, as its name

indicates, is rock either so seamy and broken

by folding or compression, or so disintegrated,

as to require an arch, generally much lighter

than those necessary in soft ground. According

to the method generally adopted in driving

a tunnel through soft ground, the first step is,

if practicable, to open out a small bottom heading

or adit, for the double purpose of draining

the ground above and making an opening

through which to carry away the material

subsequently excavated; this heading also is

required for passing in the materials used in

arching. Often, however, owing to long and

heavy cuttings necessary in the outside

approaches to a tunnel, it is deemed advisable to

begin with a top heading before the bottom

bench of the open cut is brought up to the

face of the proposed work. If a bottom heading

has been driven (and it is generally best to

do so when practicable in soft ground, while

the opposite rule holds in tunnelling through

hard rock), one of the methods of subsequent

enlarging that may be used is shown in figs. 3,

4, and 5. These represent the English plan,

so called, it being the one generally adopted

in England. For a full description of this

method of enlarging, see the “Engineering

and Mining Journal,” vol. xix., p. 392; also

Simms's “Treatise on the Blechingly and Saltwood

Tunnels.”

|

|

| Fig. 3. | Fig. 4. |

Fig. 3 shows the bottom

heading driven, with a section excavated and

ready for arching. The enlarging and arching

of a tunnel to its full size is generally done in

lengths or sections. If there is no top heading

previously driven, 15 or 20 ft. of an

advanced heading is excavated at the top of the

proposed work (shown in figs. 3 and 4). Heavy

longitudinal bars of timber are then successively

put in, beginning with those

numbered 3, 6, and 7. The miners gradually work

down, putting in a temporary arch of timber.

When this is done, and foundations have been

dug for the succeeding masonry, the masons

take the place of the miners, and run up an

arch under the timber, which is then

withdrawn during the excavation of the next

section, and the spaces left are securely blocked

up with pieces of timber or stone. In some

methods of tunnelling, it is deemed more secure

to brick the timber in and leave it in place,

though at a considerable cost, especially when

it is necessary to bring all the heavy timber

down a shaft or slope, and through a long

distance underground. Shafts are often sunk,

and sometimes slopes, so that the work may

be attacked from several points at once.

Fig.

5 shows the arch built, and is divided into two

portions: that on the left shows the completed

tunnel, with the ballast in place and the track

laid; that on the right shows the arch in place,

and the supporting timbers struck, but still

undrawn. Where the ground is very treacherous,

and much water is encountered, an inverted

arch is often put in across the bottom of the

tunnel, to withstand the pressure from below.

Other methods are in vogue on the continent

of Europe. A description of a new system of

tunnelling by the use of iron centres, in place

of timber, devised by himself, may be found

in Ržiha's work, cited below.—Tunnelling

through Rock. One of the methods of

tunnelling through loose rock, with subsequent

timbering and arching, is shown in figs. 6 and 7;

it is the one most used in America, and is

expeditious, though probably more expensive than

the European systems.

|

|

| Fig. 6. | Fig. 7. |

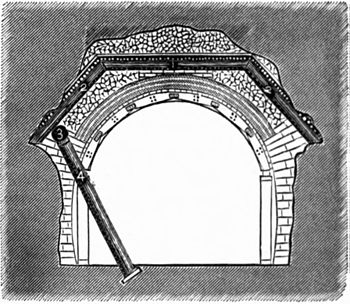

The timbers 1 and 2

are put in to support the roof and sides when

the top heading (which is generally preferred

through rock) is driven; the “legs” (2) are

occasionally braced by a bar (3), which is

supported by a raker (4), while the sides are being

dressed down when the tunnel is enlarged and

arched. The apace between the timber and

the rock above, and between the masonry and

the timber (which latter in this work should

be left in place), is packed tight with fragments

of stone, to prevent a sudden fall or stress

being brought to bear on the masonry.—Tunnelling

through solid rock by hand labor is still, in

many cases, held to be more economical than

by machinery. It is certainly so, as yet, in the

case of small tunnels through a comparatively

soft rock, where the necessary cost of a plant

of air drills and compressors would be in excess

of the economy in time gained by their use.

In driving a tunnel through rock, an advanced

heading is first driven either at bottom or top;

and this may either be of the full width of the

proposed excavation, or narrower. The heading

is always the most difficult and expensive

part of the work; for whether it be driven at

top or bottom, the miner, in removing the

remaining portion of rock, of course has much

less resistance to contend against in blasting.

Removing the top rock or the lower “bench”

is more like open-air quarrying. Longer holes

can be drilled, and heavier charges of powder

used. At the present day, however, most

heavy tunnel work is carried on with the aid

of machine drills, driven by compressed air,

which, on being liberated after acting as a

motor, serves to ventilate the work. Since

the introduction of machinery, the rate of

driving attained in tunnelling has been greatly

increased. Machine drilling was born of the

necessity for some more rapid method of

executing certain works, deemed almost too heavy

to be accomplished by ordinary means. These

were, in Europe, the Mont Cenis tunnel (see

Cenis, Mont), and in America, the Hoosac

tunnel in Massachusetts. Various types of drills

have been invented and tried abroad; among

them the Sommeiller, Dubois-François, Sachs,

Osterkamp, Brydon Davidson and Warrington,

Azolino dell' Acqua, Ferroux, McKean,

and others. Among compressors that of M.

Colladon of Geneva may be particularly noted.

At Mont Cenis the air pumps were worked by

hydraulic power. The perforators used there

were built partly from designs already

presented, but improved with original modifications

made by the engineers in charge, Messrs.

Sommeiller, Grandis, and Grattoni. A description

of the Sommeiller machines may be found

in the Portefeuille économique des machines

(1863). The Mont Cenis tunnel was begun by

hand labor in 1857, and finished in 1871, at a

total cost of about $15,000,000. The following

table, from M. Opperman's Nouvelles

annales de la construction (1869), shows the rate

of advance in that work by hand, and the

increased rate attained immediately after the

first introduction of machinery down to 1865,

working throughout with two headings:

| YEARS. | By hand, metres. |

By hand and machinery, metres. |

By machinery alone, metres. |

| 1857 | 38 | .... | ..... |

| 1858 | 459 | .... | ..... |

| 1859 | 369 | .... | ..... |

| 1860 | 343 | .... | ..... |

| 1861 | .... | 363 | ..... |

| 1862 | .... | 623 | ..... |

| 1863 | .... | .... | 802 |

| 1864 | .... | .... | 1,807 |

| 1865 | .... | .... | 1,223 |

The St. Gothard tunnel, also through the Alps,

is now (1876) in progress. From a late paper

on the subject by Daniel K. Clark, M. Inst.

C. E., London, we obtain the following general

facts concerning it. The length of the tunnel

is to be 16,295 yards or 9¼ m. The contract

prices sum up to a total estimated cost of

£1,896,945. Construction was begun in the

autumn of 1872, and the total progress

attained (two headings) up to Aug. 31, 1875,

was as follows:

| YEARS. | By hand, yards. |

By machine, yards. |

Total, yards. |

| 1872 | 182 | .... | ..... |

| 1873 | 205 | 972 | ..... |

| 1874 | .... | 1,951 | ..... |

| 1875 | .... | 1,824 | 5,084 |

The heading is driven at the top, about 8 ft.

square, dynamite being used as an explosive.

Dubois-François perforators were first used,

making an average advance of 6.63 lineal feet

a day. They were succeeded by Ferroux's,

the daily advance being raised to 10.11 ft.

Subsequently the machines of two or three

inventors, Dubois-François, McKean, and

Ferroux, were placed and worked together on

the same carriage; and it is said by M. Louis

Sautter, in an official report published in the

Revue industrielle, Aug. 18, 1875, that the

improved McKean drill has proved to be

decidedly superior to any of its competitors; its

best work on competition, with 6½

atmospheres of pressure, was a penetration of 12

in. a minute. While actually at work, its rate

will vary from 3 to 8 in. a minute, with about

800 strokes. The power is derived from water

through the agency of turbines. The cylinders

or air pumps of the compressors are 18.1 in.

in diameter, and the stroke is limited to 17¾

in., in order that the mean speed of piston may

not exceed 266 ft., or 90 revolutions a minute,

the turbine making 390 turns. The compressed

air is cooled on Dr. Colladon's system; every

piece that is in contact with the air when

undergoing compression being cooled by

currents of cold water, passed through air-tight

envelopes. It is calculated that at the present

rates of advance the St. Gothard tunnel may

be finished during the summer of 1879, or

within seven years from the date of M. Favre's

contract.—In America, both North and South,

many tunnels have been built, the modern ones

being mostly driven since the introduction of

railroads. Until the building of the Hoosac

tunnel in Massachusetts, all tunnelling through

rock in the United States was done by hand

labor, by the methods above described. The

project of tunnelling the Hoosac mountain was

broached as early as 1825. In that year a board

of commissioners, with Loammi Baldwin as

engineer, was appointed to ascertain the

practicability of making a canal from Boston to

the Hudson, in the vicinity of the junction of

the Erie canal with that river. Their report

(“Massachusetts Commissioners' Report,” 1826,

p. 141) declares that “there was no hesitation

in deciding in favor of the Deerfield and Hoosac

river route,” and that “there is no hesitation

therefore in deciding in favor of a tunnel;

but even if its expense should exceed the other

mode of passing the mountain, a tunnel is

preferable.” Railways being shortly after

introduced, the canal project was dropped. In

1828 surveys were made for three routes to

afford Massachusetts railway connection with

the west, viz., by Greenfield, by Northampton,

and by Springfield. The last or southern route

was chosen. The work was not begun

immediately, but Massachusetts never lost sight of

the advantage of a direct route to the Hudson

river. This was finally accomplished in 1842,

by the completion of the Western railroad to

Albany. In 1848 application was made for a

charter for a railroad from the terminus of

the Vermont and Massachusetts line, at or near

Greenfield, through the valley of the Deerfield

and Hoosac, to the state line, there to unite

with a railroad leading to Troy. The location

was filed in the clerk's office of Franklin

and Berkshire counties in November, 1850. In

1854 an act was passed “to enable the Troy and

Greenfield railroad company to construct the

Hoosac tunnel,” by which the state, on certain

conditions, lent its credit to the amount of

$2,000,000. The estimated cost of the proposed

double-track tunnel was $1,948,557, and of the

road and equipment $1,401,443; total, $3,350,000.

Still the company were unable to raise the

funds necessary, in addition to the state loan.

In 1855 a contract was made with E. W. Serrel

and co., under which some work was done;

and another was made with them in 1856 for

the construction of the road and tunnel for

$3,500,000, they subscribing $440,000. This

contract also fell through, as did one made

with H. Haupt and co. in the same year, by

which the railroad company agreed to pay

$3,880,000 for the completion of the road and

tunnel. In 1858 a contract was again made

with H. Haupt and co., by which the contractors

themselves agreed “to assume the labor

of collecting subscriptions and of carrying on

and completing the Troy and Greenfield railroad

and the Hoosac tunnel.” Under this

contract H. Haupt and co. were to receive

$2,000,000 in bonds of the state of Massachusetts,

to be exclusively appropriated to work done

on the tunnel; $900,000 in mortgage bonds of

the company; and $1,100,000 in cash, through

cash subscriptions and capital stock of the

company. Under this contract the work was

vigorously prosecuted up to July, 1861, when,

a difference arising between the contractors

and the state engineer, a certificate for the

amount claimed by the former on a payment

was refused, and the work was thereupon

abandoned by them. In 1862 an act passed

the Massachusetts legislature, providing “for

the more speedy completion of the Troy and

Greenfield railroad and Hoosac tunnel.”

Under this act a board of commissioners was

appointed to examine into the matter on the

part of the state. At the request of these

commissioners, the Troy and Greenfield railroad

company, acting under the authority of

certain provisions of the act, surrendered to

the commonwealth of Massachusetts, under

the several mortgages held by said

commonwealth, the road and property of the company;

such surrender having been authorized by the

board of directors, by a vote passed on Aug.

18, 1862. This action was ratified by a vote

of the stockholders, and on Sept. 4, 1862, the

commissioners took possession of the road and

its property. The commission after a full

examination made a thorough report (dated Feb.

28, 1863), embracing the three following most

valuable sub-reports: 1, a report of Charles

E. Storrow on European tunnels; 2, a report

by Benjamin H. Latrobe on the Hoosac

tunnel; 3, a report by James Laurie on the Hoosac

tunnel and the Troy and Greenfield

railroad. In conclusion the commissioners

recommended that the work should be

undertaken by the commonwealth. At this point

the cost and estimates were as follows:

| Amount advanced by the state up to the date of | |

| the commission | $1,431,447 |

| Estimated cost by the commission of completing | |

| the tunnel (double track) | 3,218,323 |

| Estimated cost of putting the road from Greenfield | |

| to the mountain in running order | 652,060 |

| Estimated cost of construction of two miles of road | |

| from western portal of tunnel to North Adams | 67,500 |

| Estimated additional cost of depot buildings, &c. | 75,000 |

| Estimated cost of rolling stock | 275,000 |

| Total estimated final cost of road and tunnel | $5,719,330 |

At this time, according to the report of James

Laurie above noted, the condition of the work

proper was as follows:

| Whole length of the proposed tunnel, feet | 24,416 | ||

| Deduct portion already excavated at each end | 2,400 | ||

| Deduct portion between shaft and proposed | |||

| western portal of tunnel | 1,850 | — | 4,250 |

| Leaving to be excavated under the mountain | 20,166 |

The shaft here referred to was on the western

slope of the mountain, 325 ft. in depth. Mr.

Laurie estimated that by sinking a central

shaft about 1,000 ft. deep and working therefrom

(which was afterward done) the tunnel,

advancing at the rates respectively of 55 ft. a

month from the two end portals, and 40 ft.

each way from the shaft, would be completed

in 11 years from date, i. e., in 1874; this

estimate being based on the supposition that the

central shaft would reach bottom in four years

from its commencement. Work was resumed

on the tunnel under the auspices of the state

in October, 1863, under the control of the

same board of commissioners, who appointed

Thomas Doane chief engineer in charge. The

governor at the same time appointed Benjamin

H. Latrobe of Baltimore state consulting

engineer of Hoosac tunnel.—Mr. Laurie in his

report to the commissioners says that shortly

after the Troy and Greenfield railroad was

chartered, the attention of inventors was turned

to the subject of tunnelling machines. One

was constructed at South Boston in 1851,

especially for the Hoosac tunnel, which weighed

about 70 tons, and was designed to cut out a

groove around the circumference of the tunnel

13 in. wide and 24 ft. in diameter, by means

of revolving cutters; the central core left was

to be subsequently blasted out with gunpowder.

It is reported to have cut, on a trial

made March 16, 1853, on a vertical face of

rock near the proposed entrance of the tunnel,

at the rate of 16½ in. an hour, and under

more favorable conditions at a previous trial

20 in. an hour. Various trials were made with

this machine, the total distance cut by it

amounting to about 10 ft., but it did not prove

successful. A second machine constructed at

Hartford, and known as the “Talbot tunnelling

machine,” also working on the principle

of revolving cutters, and adapted to cut out a

core 17 ft. in diameter, was tried about this

time near Harlem, but proved a failure. A

third machine was constructed in New York,

adapted to cut a core of 8 ft.; this was adopted

by Mr. Haupt during the continuance of

his contract, in the early days of the tunnel,

but also proved a failure. Experiments were

instituted by Mr. Haupt himself, while engaged

with his contract at Hoosac, toward the

elaboration of a percussion drill; but in 1861 the

termination of his contract for a time put an

end to them. Afterward he again took up

the subject, and in 1867 published a description

of the Haupt drill. By the time this

invention had been perfected, the Burleigh

drills, which have since attained so great a

reputation (see Blasting), had been adopted

and were in full use at Hoosac. They were

first tried in June, 1866, under the direction of

the commissioners, and even in their crude and

unimproved condition were favorably noticed

in Chief Engineer Doane's report. In January,

1867, the office of chief engineer was abolished,

and the engineer corps reduced to one resident

engineer, W. P. Granger; Mr. Latrobe still

supervising as consulting engineer. In October,

1867, owing to the accidental lighting of some

naphtha at the central shaft, the head house,

shaft buildings, &c., were consumed, and 13

lives were lost. Previous to this time portions

of the work had been let out by contract, Messrs.

Dull, Gowan, and White having the east and

central shaft headings, through rock, and Mr.

B. N. Farren the west end, through soft ground,

including the arching of the same. Owing to

the above mentioned accident, Messrs. Dull,

Gowan, and White voluntarily surrendered

their contract, received their pay, and

abandoned the work, returning it to the hands of

the commissioners. Benjamin D. Frost was

appointed superintending engineer in May,

1868, and on Dec. 24 of that year a contract

was effected between Messrs. Shanly brothers

of Montreal and the commonwealth of

Massachusetts for the final completion in full of

Hoosac tunnel. The dimensions were to be:

“in rock, unarched, 24 ft. wide and 20 ft.

high, in the clear; where arching required, 26

ft. wide and 24½ ft. high (above the rail), in

the clear.” The prices bid in the contract

varied in the different portions of the work,

and also according to whether the work was

“already begun,” “to be finished,” or for

“extension of full-sized tunnel.” The bids

accepted for the latter item were as follows:

east end section, per cubic yard, $11; central

section from shaft, $14; west end section

(part soft ground), $12; for arching part of

the tunnel with brick, per thousand of bricks

laid, $22. The total price agreed on for the

work specified by the contract was $4,594,268,

the whole to be done by March 1, 1874. At

this time Mr. Latrobe resigned as consulting

engineer; and that post, after the successive

resignations of James Laurie and Edward S.

Philbrick of Boston, is now (1876) held by

Thomas Doane. The work was vigorously

attacked by the Messrs. Shanly at all points.

The Burleigh drills and compressors were used

throughout their contract with excellent

results. Under their patronage, the manufacture

of nitro-glycerine (previously used in the

tunnel) was carried on and improved by George M.

Mowbray of North Adams. The east heading

met the one driven east from the central shaft

on Dec. 12, 1872; the west heading met the

one driven west from the shaft on Nov. 27,

1873; the errors in alignment and levels were

astonishingly small, especially as the former

meeting was at a distance of 1,563 ft., the latter

of 2,056 ft., from the shaft, down which the

plumb lines had to be carried over 1,000 ft.

The Messrs. Shanly concluded their contract and

effected a final settlement Dec. 22, 1874.

Independently of the contract taken by them, an

agreement was entered into between the state

and B. N. Farren, on Nov. 19, 1874, to do

certain arching and enlarging at the eastern portal

of the tunnel. By authority of an act passed

by the legislature in 1874, a commission of

experts, comprising Prof. T. Sterry Hunt of Boston

and Prof. James Hall of Albany as geologists,

and Thomas Doane, Josiah Brown, and Daniel

L. Harris as civil engineers, was appointed to

examine and report on the amount of arching

that would be still necessary. Their reports

are embodied in that of the commission of

1875, as is also a report from Edward S.

Philbrick, consulting engineer, recommending an

additional amount of 1,600 ft. of arching,

besides that included in the Shanly contract.

Work on this arching is still (March, 1876) in

progress. Under a law of 1874 a board of

corporators of the Boston, Hoosac Tunnel, and

Western railroad was created, who reported

that the tunnel had up to that time cost the

state about $14,000,000. By a subsequent act

of 1874 the corporators were superseded by

five directors, to whom the interest of the state

in the tunnel and railroad was transferred.—The

next tunnel in the United States in which

machine drills were introduced with effect,

after their practicability had been

demonstrated at Hoosac, was the Nesquehoning tunnel

in Pennsylvania, constructed under the

direction of J. Dutton Steele as chief engineer.

(See paper by J. Dutton Steele in “Transactions

of the American Society of Civil

Engineers,” 1871.) Here the Burleigh drill and

ordinary black powder were used. The

Musconetcong tunnel, on the Lehigh Valley railroad

extension through New Jersey, was the

next heavy piece of work in the eastern states

on which machine drilling was adopted. This

tunnel was begun in April, 1872, and finished

in June, 1875, under the charge of Robert H.

Sayre, chief engineer and general superintendent

of the Lehigh Valley railroad company.

Charles McFadden of Philadelphia took the

contract, and completed what has been

conceded to be one of the heaviest pieces of tunnel

work ever attempted in America, and yet

one of the most rapidly built. Every modern

appliance was used. The Ingersoll drill was

adopted, about 26 being kept on hand, and from

16 to 18 in constant use. Four Burleigh

compressors supplied the air required at the west

end, and four Rand and Waring compressors at

the east. Dynamite was used throughout as an

explosive, and gave entire satisfaction. Very

heavy difficulties were encountered in the

prosecution of the work, owing to the large bodies

of water met with. The total length of the

tunnel was a little less than one mile. It was

begun by sinking a slope to grade on the western

side of the mountain, about one third of

the distance through, virtually dividing the

tunnel into one third of soft ground working

at the west, and two thirds of very hard ground

at the east. The headings were started east

and west from the bottom of this slope in

November, 1872. The east heading had been

started in July, 1872. Owing to the heavy

cutting necessary at the west end, the heading

could not be connected with those from

the slope, and from a shaft subsequently sunk,

until November, 1873. In May, 1873, so

heavy a body of water was struck in the slope

heading going east, that it could not be

controlled. The miners were driven out, and the

slope half filled. The water undermining the

props and backing of the timbering in the

slope, part of the roof fell in, and the work

at that point had to be abandoned temporarily.

A shaft was then sunk west of the slope, and

headings were driven east and west to tap and

draw off this water. Here again new and

even heavier bodies of water were encountered,

resulting in great expense and much

loss of time. Finally the difficulties were

overcome, the water tapped, and work

resumed on the original slope heading going

east, which met the east heading coming west

in December, 1874, the errors in alignment

and level being less than half an inch. (For

further details on the construction of this tunnel

see a paper by Henry S. Drinker in the

“Transactions of the American Institute of

Mining Engineers,” vol. iii.) With the admirable

and delicate instruments now so readily

obtainable, it would require a positive effort of

carelessness on the part of the engineer to

entail any serious error in tunnel surveys.

Especially noticeable among instruments are those

recently perfected by Messrs. Heller and

Brightly of Philadelphia, who have made a specialty

of tunnel transits.—The above described three

tunnels have been taken as particular

examples, because they are the latest driven at

the present time (March, 1876), and are the

best examples of the present stage of the art

of tunnelling in the United States. A large

tunnel in Nevada, known as the Sutro tunnel,

has been in process of construction with

machinery for some years. (See Nevada.) It

is intended to serve as an adit to the

Comstock lode. (See “Report of United States

Sutro Tunnel Commission,” Washington, Jan.

6, 1872.)—One of the first tunnels in the United

States was on the Alleghany Portage railroad

in Pennsylvania. It was built in 1831,

double track, 900 ft. long; contract price, $1 47

per cubic yard; total cost, 14,857 cubic yards,

$21,840. Another early work was the Black

Rock tunnel, on the Reading railroad, built in

1836. This was 1,932 ft. long, and the

excavation proper of the tunnel cost $125,935.

According to data furnished by Mr. B. H.

Latrobe of Baltimore, there are 44 tunnels on

the line of the Baltimore and Ohio railroad

and its branches, with an aggregate length of

37,861 ft., or 7 m. 901 ft., the tunnels varying

from 80 to 4,100 ft. in length. The Sand Patch

tunnel, on the Pittsburgh and Connellsville

branch, was begun in 1854 and finished in 1871.

The work during this time was intermitted

for a total period of nine years, owing chiefly

to the financial embarrassments of 1858. It

was driven through the old red sandstone, and

cost nearly $500,000. The Kingwood tunnel,

4,100 ft. long, was begun in September, 1849,

and finished in May, 1852, at a total cost,

including excavation and arching, of $724,000.

The Broadtree tunnel, 2,350 ft. long, on the

same road, begun in the spring of 1851, was

completed in April, 1853, at a total cost

(excavation and arching) of $503,000. The Chesapeake

and Ohio railroad is 423 m. long, and

has 7 m. of tunnelling; the Big Bend tunnel,

on the Greenbrier division, is 6,400 ft. long.—Of

the rates of progress attainable by

machine drilling, a fair average can be deduced

from three large tunnels driven through

different kinds of rock. At the Hoosac tunnel,

through mica schist and micaceous gneiss, with

nitro-glycerine, the progress attained by Shanly

brothers at the east end in 1869 averaged

139½ ft. a month, and in 1870, 126½ ft.; at the

west end in 1870, 100¼ ft. In sinking the

central shaft 1,080 ft. in depth, through rock, the

average total progress per working month was

21 ft., but the 230 ft. sunk by Shanly brothers

was driven in 7½ working months, or at the rate

of 30.7 ft. a month. At Nesquehoning, through

conglomerate, the average attained in 12

months' driving was 100 ft. a month; while

through red shale an experience of two months

gave an average of 160 ft. a month. Common

black powder was used, the consumption in

the conglomerate being about 6 lbs., and in red

shale 3½ lbs. per cubic yard of rock broken. At

the Musconetcong tunnel the average monthly

advance through a very hard syenitic gneiss,

pronounced harder by experts familiar with

both than any body of rock met in the Hoosac

tunnel, was in 1874: east heading, average of

12 months, 115.8 ft.; west heading, average

of last 6½ months, when steady work was

attained, 136.8 ft. At this tunnel a shaft was

also driven 110 ft. in depth through soft ground,

with timbering, at an average rate of 24¼ ft. a

month. The prices bid at the present day for

tunnel excavation vary from $4 to $7 and $8

per cubic yard. But the contract prices are not

always a sure criterion as to the final cost; $6

per cubic yard is a medium bid. Very heavy

and expensive tunnel work is often done in

constructing underground railways through cities.

In these the plan generally adopted is first

to make an open-air excavation through the

streets, then build the arches and fill in the

ground again. A very heavy tunnel was lately

finished under the London docks, passing also

under some large warehouses, and needing very

careful work. The quantity of water pumped

was enormous. The final cost was at the

rate of £390,000 a mile.—Subaqueous Tunnels.

Among these should be particularly noted the

first one built under the Thames at London.

Except however in view of its vast expense,

and the fact that it was the forerunner of modern

subaqueous tunnelling, its record at the

present day, since the system has been further

developed, has no very practical interest. It

was begun in 1807, intermitted, and resumed

in 1825, under Sir M. I. Brunel, intermitted

again, and at last completed and opened for

foot passengers in 1843. Its total length is

1,200ft.; final cost nearly £1,200 per lineal

yard advanced. (See London, vol. x., pp.

616-617.)—A tunnel that has attracted much

attention throughout both Europe and this

country is the one at Chicago, driven out

under Lake Michigan, for the purpose of obtaining

pure water for the city. This tunnel, begun

in March, 1864, and completed in March, 1867,

was entirely original in plan; the engineer

was Mr. E. S. Chesbrough. A crib was first

sunk in Lake Michigan, about two miles from

the shore, 58 ft. in horizontal outside measurement

on each of the five sides, and 40 ft. high.

The inner portion or well has sides parallel

with the outer ones, 22 ft. long each, leaving

the distance between the inner and outer faces

of the crib, or thickness of the breakwater, 25

ft. This breakwater was built on a flooring of

12-inch white pine timber, laid close together.

The outer and inner vertical faces, and the

middle wall between them, were all of solid

12-inch white pine timber, except the upper

10 ft. of the outside, which was of white oak,

to withstand better the action of the ice. The

outer and inner walls were strengthened and

connected with brace walls and cross ties of

12-inch timbers, all securely bolted. The crib

was built on land, launched, towed into place,

filled with atone, and sunk. An iron cylinder,

cast in 9-foot sections, of 9 ft. internal diameter

and 2¼ in. thick, was then lowered within

the crib to the bottom of the lake; and this

cylinder was connected with the land two miles

distant by a tunnel under the lake bottom.

Gate wells were constructed in the sides of the

crib, and after the completion of the tunnel

the top section of the cylinder, extending above

water level, was removed, and the water

admitted through a screen. The tunnel, of

circular cross section, was driven through a stiff

blue clay; diameter of excavation 5 ft.,

subsequently lined with two rings of brick. The

final cost in full to the city was $457,844.

According to the statements and books of the

contractors, the items were: crib and outer

shaft, $117,500; land shaft, $12,000; tunnel

proper, $195,000; total, $324,000. The balance

of the expenditure was used in necessary

contingencies. For full details of this work see

“Eighth Annual Eeport of the Board of Public

Works” (Chicago, 1869); also a report of

Prof. W. P. Blake, commissioner of California

to the Paris exposition (1867). A second tunnel,

7 ft. in diameter, extending to the same

crib, was completed in July, 1874, at a total cost

of $411,510; and two tunnels for traffic have

been constructed under Chicago river. A tunnel

under Lake Erie, at Cleveland, Ohio,

begun in August, 1869, finished in March, 1874,

is similar in plan, purpose, and construction

to the one first driven under the lake at

Chicago, except that much greater difficulties were

encountered in its construction, from meeting

several bodies of very soft ground. It is

6,606 ft. in length, and the total cost amounted

to $320,352.—It was estimated by Capt. Tyler

in 1873 that between 300,000 and 400,000

persons yearly crossed the English channel at

Dover, that the number was constantly increasing,

and that if a tunnel were built it would

probably be doubled. The idea of a tunnel

under the channel was first broached by M.

Mathieu, a French engineer, who laid plans

for one before Bonaparte in 1802. Owing to

the subsequent disturbances the projector and

his plans were lost sight of. Subsequently

plans were proposed by M. Thomé de Gamond,

Dr. Payerne, Messrs. Franchot and Tessier,

Favre, Mayer, Dunn, Austin, Sankey, Boutet,

Hawkins Simpson, Low, Boydon, Brunlees,

Waenmaker, and others. To M. Thomé de

Gamond is conceded the credit of pushing the

project to its present advancement. In 1872

the present channel company was incorporated,

Sir John Hawkshaw, Mr. James Brunlees, and

M. Thomé de Gamond being appointed the

engineers. The route finally adopted places the

tunnel on a line drawn from St. Margaret's bay

near the South Foreland, on the English side, to

a point between Sangatte and Calais in France.

The total proposed length of the tunnel is 31

m., of which 22 m. will be under the channel.

Should the preliminary tests prove favorable,

it is proposed to begin the actual construction

by sinking shafts on either shore to the depth

of 450 ft. below high-water mark. Driftways

will be driven from the bottom of these for

the drainage of the subsequent tunnel proper.

The tunnel, if constructed, is to begin 200 ft.

above the driftway, and will be driven from

both ends. It is to be through the chalk, and

in no part of it will there be less than 200 ft.

of ground between the crown of the arch and

the bed of the channel. It will be on a down

grade of one foot in 80 to the junction of the

drainage driftway, and then on an up grade

of one in 2,640 to the middle of the strait. It

is proposed to drive the driftway or heading

with Dickinson Brunton's machine for tunnelling

through chalk, which works like an auger

boring wood. It is believed, from actual work

done, that this machine will advance at the

rate of from a yard to a yard and a quarter an

hour. At this rate it would require two years

to construct the driftway, driving from either

end, at an estimated cost of £800,000. After

the heading has been driven through, it has

been estimated that four years' time and an

outlay of £4,000,000 will finish the work,

including arching; but Sir John Hawkshaw and

his associates consider it best, before beginning

the work, to double this figure as an

estimate. The preliminary works to be undertaken

are the sinking of two shafts at either

extremity of the tunnel, from which an ordinary

mining driftway is to be driven about

half a mile out under the sea, the cost of which

is estimated at £160,000. This done, the engineers

will be better able to judge of the ultimate

practicability of the work.—See Lehrbuch

der gesammten Tunnelbaukunst, by F. Ržiha (6

vols., Berlin, 1865-'72); and Der Tunnelbau,

by J. G. Schön (4to, Vienna, 1866). There is

no complete work in English on modern

tunnelling. The facts in this article are largely

drawn from a practical treatise on American

and European tunnelling, now (1876) in course

of preparation by Henry S. Drinker, E. M., of

Philadelphia.