The Working and Management of an English Railway/Chapter 4

CHAPTER IV.

Permanent Way.

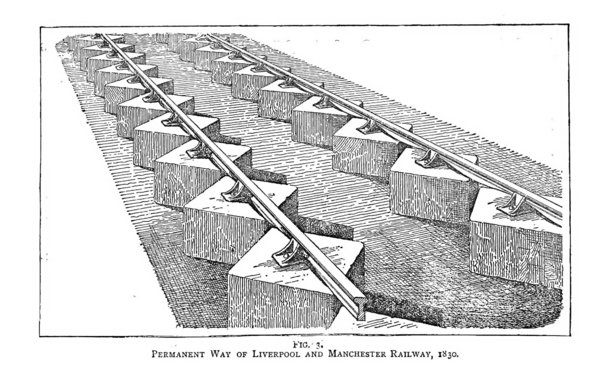

We have had occasion to remark in a former chapter that the permanent way of a first-class English railway of the present day represents a very advanced stage of development as compared with the rude methods of construction of the earlier railways, and perhaps this fact can most forcibly be illustrated by a brief retrospect of the various changes and improvements which have from time to time been introduced, and which have finally resulted in giving us the magnificent steel track of the present age, upon which a train weighing, with its engine, nearly 300 tons may travel with ease and safety at a speed of from fifty to sixty miles an hour.

As we have already seen (Chap. I.), the earliest conception of a railway or tramway found its embodiment in a wooden track consisting of oak rails laid upon blocks of wood about two feet apart, and upon which carts with flanged wheels were drawn. Tramways of this description are said to have existed in the neighbourhood of Newcastle-on-Tyne more than two hundred years ago. Nicholas Wood, in his "Treatise on Railroads," published in 1825, gives the Coalbrookdale Iron Works Company the credit of being the first to construct cast-iron rails, which they are said to have done in 1767, the rails being 5 feet long,

In 1776 we find in use, at the Sheffield Colliery, cast-iron rails of an angular section (Fig. 1), laid upon wooden sleepers, and which required no flanges to the wheels. Tramways constructed in this manner exist, and are in use in some parts of the country at the present time.

Fig. 1.

Sheffield Colliery Tramway of 1776.

In 1789 a railroad or tramway was constructed at Loughborough, having cast-iron "fish-bellied" rails, from three to four feet in length, resting on stone blocks instead of wooden sleepers, and requiring flanged wheels (Fig. 2).

The first malleable iron rail was patented by J. Birkenshaw, in 1820, and this form of permanent way,

with rails weighing 28 lbs. per lineal yard, was used on the Stockton and Darlington Railway, and was subsequently adopted by George Stephenson when he constructed the Liverpool and Manchester Railway; but he increased the weight of the rails to 35 lbs. per lineal yard, their length being 15 feet. The rails rested for the most part on solid stone blocks, laid diamond fashion, but on embankments and on peaty ground oak sleepers were used (Fig. 3).

These rails, as will be seen from the illustration, were of the "fish-bellied" pattern, but in practice, and as the demand increased, these were found troublesome to roll, and this difficulty led to the introduction of the flat-bottomed or "flat-footed" section of rail, combining a solid head with a flanged base. This is known as the "Vignoles" rail (Fig. 4, No. 4), and, although still largely used in the colonies and abroad, it is very little in use in this country except in the case of lines laid down for temporary use by contractors.

Another form of rail, known as the "Bridge" rail (Fig. 4, No. 3), was introduced by Brunei contemporaneously with the "Vignoles" rail, and this section of rail, laid upon longitudinal instead of transverse sleepers, was adopted as the standard form of permanent way on the Great Western Railway.

In 1837 the double and equal-headed reversible rail, as shown by Fig. 4, No. 5, weighing 84 lbs. per lineal yard, was originated by Joseph Locke, and was adopted on the Grand Junction Railway. It was originally intended, when one head was worn out, to turn the rail and use the other, but it was found in practice that, unless the rail was turned very frequently, the lower head became indented, where

it rested in the chairs, to an extent which rendered it unfit for a running surface. This section of rail is still in use on some of the railways in this country, but it is being rapidly superseded by the "bull-headed" section (Fig 4, No. 6), which is simply a refined and enlarged copy of George Stephenson's single-headed rail, and was used in very nearly its present form on the Shropshire Union Railway some forty years ago.

Up to the year 1847 the ends of the rails rested in joint chairs, but in that year Mr. Bridges Adams introduced the suspended joint with fish-plates (Fig. 5, No. 1), by which a much greater degree of elasticity was imparted to the permanent way. The innovation was not adopted upon the London and North-Western Railway until the year 1853, but although, since then, many other plans have received a trial, and some hundreds of patents have been taken out, this form of connecting the rails is found to be the most simple and effectual, and, with one improvement, which is shown by Fig. 5 No. 2, is still used universally on the London and North-Western Railway.

Rails have gradually increased in length, in depth, and in sectional area, but perhaps the greatest improvement which has been effected in them is in the change of material from malleable iron to Bessemer steel. Steel is not only found to be more homogeneous, generally wearing uniformly from end to end, but its strength is half as great again as that of iron, and the rail may thus be reduced in weight by abrasion and corrosion to an extent that would be unsafe in an iron rail. On the other hand, it is only fair to add that steel corrodes more rapidly than iron (in the proportion of about five to four), and in tunnels, and in manufacturing districts

where sulphurous and other acid gases are present in the atmosphere, the life of the rail is shortened to a material extent. On the whole, however, the balance of advantages is greatly in favour of steel.

Fig. 4, No. 5 (a), shows the section of a double-headed rail which has been in use for twenty years in the main line at a large station, and subsequently for five years in a siding, and one head of which is quite worn out This is, of course, an extreme case, but it very forcibly indicates the possible reduction of sectional area in a rail constructed of first-class material. On the other hand, Fig. 4, No. 6, shows the section of a rail which is no longer fit for the main line, but might still be used in a siding; in both these cases it will be observed that corrosion has more or less had the effect of reducing the portion of the rail not in contact with the wheels, and that the original shape of the head of the rail is no longer recognisable, so great is its reduction and deformation under the heavy percussive and abrading forces to which it has been subjected.

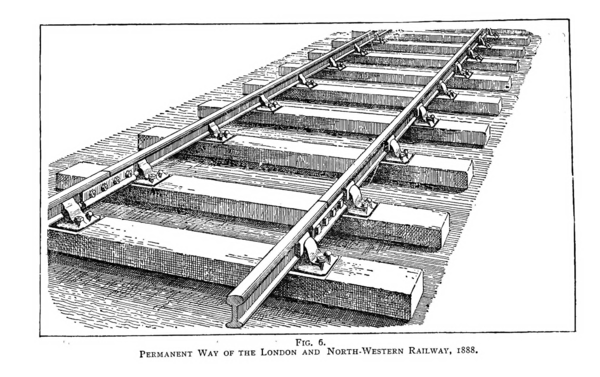

The improved form of permanent way actually in use upon the London and North-Western Railway at the present time is seen in Fig. 6. It consists of wooden sleepers, laid transversely, and which are of well-seasoned Baltic timber, into which creosote oil has been forced under pressure to the extent of 3¾ gallons to each sleeper. The sleeper, which is 9 feet in length, 10 inches wide, and 5 inches deep, when creosoted, weighs 150 to 160 lbs. To each sleeper two cast-iron chairs, each weighing 45 lbs., are secured by two iron spikes and two galvanised iron screws, a layer of hair felt being interposed between the sleeper and the chair. The spikes are cup-headed, slightly tapered, 6 inches

in length, and weigh 19 oz. each. The screws have a hexagonal head, are also slightly tapered, and weigh 20 oz. each, their length being 6¾ inches. A creosoted oak ferule or socket is inserted in each hole in the chair, through which the screws are driven, so as to obtain a mechanical fit by simple means. The steel rails, which are laid in the chairs, are of the single-headed section, 30 feet in length, and weigh 900 lbs., or 90 lbs. per lineal yard. It may be mentioned that over bridges, and for some other special purposes, about 10 miles of rails have been laid upon the London and North-Western Railway which are 60 feet in length.

Each 30 feet rail rests on ten sleepers, and is secured in its place by creosoted oak keys 6 inches long, 3⅜ inches wide, and 2⅛ inches thick, driven between the rail and the chair, outside the rail. The fish-plates by which the rails are joined (Fig. 5, No. 2) are 20 inches in length, 5¼ inches deep, and weigh 54 lbs. per pair. The four bolts by which they are secured to the rails are square-headed, with a Whitworth thread 9 to the inch, the nuts being hexagonal.

A certain number of iron and steel sleepers have been laid down on the London and North- Western Railway experimentally, the first step in this direction having been taken eight years ago. The results have been varied, a percentage of the sleepers having failed, while, on the other hand, a larger percentage appear to be standing well; but, on the whole, a sufficient time has not yet elapsed to fairly test their durability.

Permanent way engineers insist that the first and last requisite for the maintenance of a sound and good permanent way is a perfect system of drainage. The formation requires to be kept as dry as possible, and to this end, if the material is of a porous nature, retentive of moisture, it should be well drained by means of rubble or pipe drains; if it is not of a porous character as, for instance, stiff clay or rock, the surface should be formed with a section similar to that of a well-constructed macadamized road, so as to throw the water quickly off its surface to the side ditches. Upon such a formation should be placed a layer of bottom ballast of uniform size and durable quality, free from dirt or any substance which absorbs and retains moisture. Upon the bottom ballast the sleepers will be laid, and with a sufficient quantity of top ballast, which should be equally clean and durable, although, preferably, of smaller size, the line will be raised and adjusted to its intended level, the plate-layers, in laying the sleepers, taking particular care to obtain a uniformly solid and level bed for each sleeper, so that it may take precisely its proper share—no more and no less—of the weight of the passing trains. Skill and attention displayed at this stage meet with their due reward, and much subsequent trouble and anxiety is saved to the permanent way inspector, who has a length of road to maintain, if he takes care that his sleepers are not bedded on irregularly-sized lumps of stone, that his chairs are fixed to a uniform gauge, and that the sleepers are placed at right angles to the direction of the line, and well packed, or beaten up, as firmly under one rail as the other. He should see that his rails are not bent in unloading, that all crooked or defective fish-plates, spikes, and screws are rejected; that his curves are of uniform curvature, and with super-elevation proportioned to the radii, and that many other apparently insignificant precautions are not neglected, all of which contribute to the construction of a sound and perfect permanent way over which

heavy trains may travel safely and smoothly at a high rate of speed, and with a minimum wear and tear and expenditure of motive power.

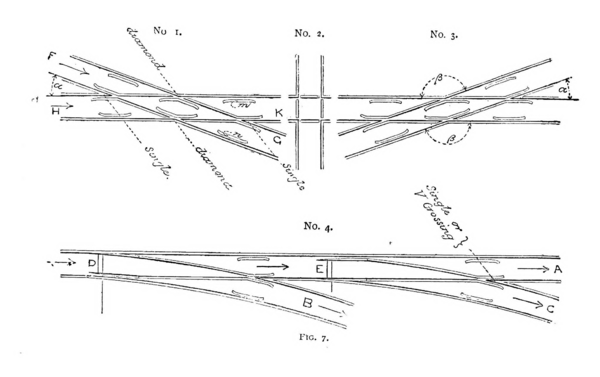

The intersection of one rail with another at any angle is termed a "crossing," and these crossings are so constructed with wing rails and check rails as to guide the flange of the wheel, and ensure its taking the required direction at the point of intersection. The simplest form of crossing is where the rails intersect each other at right angles (Fig. 7, No. 2), but such crossings are of rare occurrence. When the rails intersect at any other than a right angle, the crossings are of two types. When the external angle of intersection is acute (as at a, Fig. 7, Nos. 1 and 3), the crossing is known as a single or "V" crossing, but where the angle of intersection is obtuse (as at b, No. 3), it is called a "diamond" crossing. "Diamond" crossings occur only in pairs.

For "V" crossings, check rails are provided (m and n, No. 1, Fig. 7), which, by holding one wheel on an axle to its proper course, prevents the wheel at the other end of the axle from taking the wrong side of the point of the crossing between m and n. The check rail n guides the flange when a wheel is travelling from f to g, and the check rail m guides it in the directionh to k.

From an inspection of these diagrams (Fig. 7) it will be easy to trace the course of the wheel flange, which is always on the inner side of the wheel.

To turn a train off one line of railway and on to another which connects with it, a pair of tapered moveable rails, called "switches," or "points," are made use of (see Fig. 7, No. 4). These are connected by rods with a lever in the signal cabin, and worked by

the signalman; the lever being so controlled mechanically that it is impossible for the signalman to lower the signals for a train travelling in the direction of the arrow on line "b," until the "points" or "switches" have been placed in their proper position, as at d. On the other hand, before the signal can be lowered for the line c the switches must be placed as at e.

Fig. 9 gives a view in perspective of a pair of switches, and shows the manner in which they are worked.

Fig. 8 is a view of an ordinary junction between a main line and a double branch line, with the signal cabin from which the points and signals are worked, and the home signals for the junction. The diamond crossings are marked b, and the nearest single crossing is marked a. This is a simple double junction; but where the running lines are duplicated, and there are numerous cross-over-roads and sidings connecting with the main lines, the arrangement of roads frequently becomes extremely complicated.

There is one important feature in the formation of a well-constructed permanent way, which is known as the super-elevation of the outer rail on curves. Any one who has witnessed the evolutions of a circus rider will have observed that both horse and rider, in order to maintain their balance, incline their bodies towards the centre of the ring, and the greater the speed, the greater is their deviation from the perpendicular. In order to enable a train to do by mechanical means what the rider does by muscular power—that is, to balance the centrifugal force of a train running round a curve—it is necessary for the outer rail on a curve to be raised somewhat above the inner rail, and the

Fig. 9—View in perspective of a pair of switches showing the manner which they work.

smaller the radius—that is the sharper the curve—and the higher the speed of the trains, the greater must be the super-elevation. In practice it must be adjusted to the average speed of the fastest trains that are likely to run over it—that is, the express passenger trains.

Railway curves are invariably arcs of circles of greater or less radius, except for a short length, where they join or leave the straight line. Where the radius of the curve is uniform, a uniform super-elevation is given to the outer rail, but this elevation dies away gradually to the straight line, where the rails become level. As the super-elevation decreases the radius of the curve increases until it becomes infinite, or, in other words, until the straight line is reached.

If it be asked what is the steepest gradient a railway should have, the answer is, "The best that can be obtained under all the circumstances; or, in other words, the nearest to a dead level." There are cases in which the physical conditions of a country will only permit of a railway being constructed with sharp curves and steep gradients, except at a practically prohibitive cost. It is, nevertheless, a fact that the less the deviation from a straight line and moderate gradients, the greater is the safety and economy of working; and, in constructing a main line of railway, it is frequently worth while to incur heavy outlay at the outset rather than handicap the undertaking with difficulties of working, which will place it at a disadvantage in competing with other railways for the same class of traffic, for which punctuality and speed are of the first importance.

In practice it is usually found that sharp and frequent curves are associated with steep gradients, and, upon railways which have to be constructed in this manner, the trains must necessarily be lighter, and the average speed must be considerably less than where the conditions are more favourable. Such lines are, therefore, in proportion to the traffic carried over them, more expensive to work and maintain, but as the weight of the train, the class of locomotive used, and all the other arrangements for conducting the business are specially adapted to the circumstances, such a line as this probably involves less trouble and anxiety in working than a railway which is generally level, but which has one or more long and steep gradients in its course. In the latter case, the steep gradient is the exception, and not the rule; all the conditions are adapted to the maintenance of the high rate of speed expected with heavy trains on fair gradients, and yet the engines must have sufficient adhesion and steaming power to surmount the difficulties of the exceptional gradient. In some cases the plan is adopted of attaching an auxiliary engine (called a "bank engine") to the rear of the train at the foot of the incline, but this involves an additional stoppage and the loss of valuable time, and special precautions are required to enable the operation to be performed with certainty and safety.

The extent to which the average speed of trains is affected by the mode of construction of a railway is strikingly illustrated by the following table, which gives particulars of the curves and gradients, and the speed of the trains, upon the main line of the London and North-Western Railway from London to Carlisle, upon the Buxton Branch, the Central Wales line, and the Merthyr, Tredegar, and Abergavenny Branch.

| Line. | Length of Line. | Curves. | Gradients | Average Speed. Miles per hour. | Number of Stops. | |||||||

| Less than 20 chains radius. | Between 20 & 40 chains radius. | Between 40 & 80 chains radius. | Over 80 chains radius. | Straight Line. | Percentage of Level Line. | Steepest Gradient. | Average Gradient both ways. | |||||

| Rising. | Falling. | |||||||||||

| Main line | Percent | Percent | Percent | Percent | Percent | Percent | Percent | |||||

| London and Crewe | 158 | … | … | 13 | 39 | 48 | 9 | 1 in 100 | 1 in 177 | 1 in 432 | 48½ | 3 |

| Crewe and Carlisle | 141 | … | 5 | 18 | 27 | 50 | 13 | 1 in 75 | 1 in 95 | 1 in 225 | 48½ | 2 |

| Buxton Branch | 19 | 2 | 34 | 32 | … | 32 | 11 | 1 in 58 | 1 in 66 | 1 in 78 | 36 | 2 |

| Central Wales Line | 59 | 3 | 35 | 16 | 4 | 32 | 11 | 1 in 60 | 1 in 60 | 1 in 97 | 31 | 7 |

| Merthyr Tredegar and Abergavenny | 19 | 36 | 13 | 2 | … | 49 | 5 | 1 in 38 | 1 in 35 | 1 in 44 | 22 | 3 |

It will be observed from this table that upon the Merthyr, Tredegar and Abergavenny Branch, with its steep gradients and severe curves, the trains can only run at less than half the average speed that can, without difficulty, be maintained upon the main line, and it may be added that, while upon the main line the load drawn by a goods engine is five tons to every ton of engine, on the Merthyr Branch the load is only three tons to every ton of engine, notwithstanding the low rate of speed.

The following may be mentioned as instances of specially steep gradients for short distances:—The incline to the Fruit Market at Edge Hill, near Liverpool, is 1 in 24 for 173 lineal yards, and the load which can be drawn up it is only 2½ times the weight of the engine. On the Hopton incline, on the Cromford and High Peak Railway, there is a gradient of 1 in 14 for a length of 440 lineal yards, and on this an engine is only able to draw its own weight of load.

On the other hand, on an easy gradient, a coal engine will draw from eight to ten times its own weight, and between London and Carlisle 2½ tons of passenger train load can be drawn for every ton of engine at an average speed of from 45 to 50 miles an hour, and if this is compared with the same load conveyed over the Merthyr, Tredegar and Abergavenny Branch at a speed of only 22 miles an hour, the effect of curves and steep gradients upon the working of a railway will be seen at a glance.

Sharp and reverse curves add to the train resistance and increase the risks attending a high rate of speed,and they also largely contribute to the fatigue experienced by a passenger after a long railway journey.

To maintain the permanent way of a great passenger railway in perfect working order, a very careful and complete system of organisation becomes necessary, and this, upon the London and North-Western, is carried out in the following manner:—

Three men, with a foreman or ganger, form a gang, and have charge of the constant inspection and maintenance of about two miles of double line of railway, being an average of one man to each mile of single line; but the exact number depends upon the extent of the traffic using the line, and the consequent wear and tear, and the number of junctions and sidings which have to be maintained. Every ten or twenty of these gangs are under the direct supervision of an inspector, who thus has a district of from 20 to 40 miles of railway. Every seven or eight of these inspectors are under the control of a chief inspector, who is therefore responsible for from 200 to 250 miles of railway, and who has also under him travelling gangs of ballasting men and relayers, who are employed in renewing the permanent way and carrying out alterations and additions. Each length has also a full complement of artificers, joiners, masons, bricklayers, painters, blacksmiths, etc., with their foremen and inspectors, and these men repair bridges, tunnels, stations, and all kinds of buildings which constitute the "works" of a railway. All these men, together with the Chief Permanent Way Inspector, and the men under him, are under the direction of a civil engineer of experience, who has also a staff of surveyors, draughtsmen, and clerks, with offices and workshops at the most important centre of traffic in his district. Such a section of the railway is called a "Division," and there are eight such divisions on the North- Western Railway, the eight divisional engineers being responsible to an "assistant engineer" who, together with another assistant engineer of equal rank who has charge of the construction of new railways and other important contract works, acts under the instructions of the engineer-in-chief of the Company.

The duties of the gangers comprise the daily inspection of every portion of the section of line under their charge, and the repairs of the permanent way, fences, drains, and roads. They have also to report anything they may observe to be amiss with the telegraph wires, the signals, or with passing trains more especially during storms, fogs, or heavy falls of snow. They furnish their inspectors with an account of all materials required and used, and are responsible for the work performed by the men under them, which is of a very miscellaneous character.

The inspectors of permanent way are responsible for the discipline of their men, and for keeping a correct account of the time they work, and the wages paid to them. It is their duty also to keep a record of all materials received and used, to see that every care is taken of the property of the Company, and to report to the chief inspector of the district, or to the divisional engineer, every circumstance of an unusual character which may come within their knowledge. They take charge of the renewals of permanent way, and of the operations necessary in case of floods, and of landslips of an ordinary character. In mining districts they keep careful watch, and see that the railway is lifted and maintained when subsidences occur; they daily visit portions of their districts, and are in constant personal communication with their gangers, acquainting them with all instructions issued from headquarters.

The chief inspectors of districts are responsible for the general condition of the main lines, and it is their special duty to see that a uniform standard of maintenance is kept up by each of their sub-inspectors, and that orders given by the engineer are duly observed and consistently followed out. They arrange the running of trains of materials, and provide for ballasting operations, and are in constant communication with the divisional engineers, to whom they report upon every matter affecting the permanent way.

A similar chain of supervision exists in the workshops in each district.

Periodical meetings of the divisional engineers are held, at which the various points which arise from time to time in connection with the maintenance and repair of the permanent way are discussed, and the engineers are thus enabled to compare notes and give each other the benefit of their respective experience.

The stability of the permanent way and works of a great railway is frequently threatened, and ceaseless vigilance has to be exercised to avert the dangers arising from circumstances which no human foresight can anticipate. Embankments and sea-walls are sometimes demolished by storms; landslips and the fall of rock from overhanging cliffs may cover the rails; sudden subsidences of the surface, due to mining operations, may take place; bridges and viaducts may be set on fire, or washed away by floods; dangerous compounds explode in transit, rails be torn up by collisions, or portions of tunnels may collapse. Instances of mishaps from all these causes have occurred in actual experience, and to repair the damage and restore the communication in the shortest possible time is the task which frequently has to be undertaken by the railway engineer, occurrences of the nature referred to frequently happening without the least previous warning. In such cases, the first difficulty the engineer experiences is very often in ascertaining, with any degree of accuracy, what has actually taken place, and the precise extent of the damage which has resulted, and he has next to determine what, with the time and means at his disposal, he is justified in attempting. It is often found that men, plant, and material can be more expeditiously obtained from some central depôt than from local resources, although the depôt may be a hundred miles or more from the scene of operations.

A notable illustration of what can be done in this way in an emergency by a company like the London and North-Western, possessing great resources, occurred when, in the great storm of Sunday, the 17th August, 1879, the Llandulas viaduct, on the main line of the Chester and Holyhead Railway, was undermined By flood, and washed completely away, interrupting, for the time being, the traffic between England and Ireland. For two days, until the flood subsided, nothing could be done, but within the space of five days afterwards the railway was deviated for about half-a-mile so as to strike the river at the narrowest point, and a temporary trestle bridge was erected, over which the first train passed at 2 p.m. on the 24th August, exactly seven days after the mishap occurred. The line was cut in the slope of the embankment leading to the old viaduct, and was everywhere placed upon solid ground, or upon stacks of old sleepers, so that there might be no settlement, and the line might be fit for the heaviest traffic immediately it was completed. The gradients were 1 in 23, dipping down to the river, and rising on the opposite side, and everything was finished off in the most substantial and careful manner; but of course great skill and attention were necessary on the part of the engine drivers, and the difficulty of working long and heavy trains, some of which required three engines, over these severe and changing gradients, without breaking the couplings, or heavily bumping the carriages together, can hardly be exaggerated, yet no mishap occurred, and the passengers in the trains were scarcely aware that they were travelling under unusual conditions.

The new permanent viaduct was meanwhile rapidly constructed, and was actually completed and opened for traffic on the 14th September, less than one month after the mishap. Its length is 224 feet, divided into seven spans of thirty-two feet each, and its height is fifty feet. Forty-two girders, each thirty-two feet in length, were required, and the plates and angles for each girder were rolled in one length. All these were made in the Company's own steel works at Crewe, and the whole of the material was turned out and ready for erection within seven days, the steel having been manufactured, rolled, and worked, within that short space of time.