tenon, dovetailed tenon, tusk tenon, joggle, bridle, foxtail wedging, mitre, birdsmouth, built-up, dowel. Illustrations are given of the most useful joints in general use, and these, together with the descriptions, will enable a good idea to be formed of their respective merits and methods of application.

The lapped joint (fig. 1) is used for temporary structures in lengthening timbers and is secured with iron straps and bolts; a very common use of the lap joint is seen in scaffolding secured with cords and wedges.

The fished joint (fig. 2) is used for lengthening beams and is constructed by butting the ends of two pieces of timber together with an iron plate on top and bottom, and bolting through the timber; these iron connecting-plates are usually about 3 ft. long and 14 in. and 12 in. in thickness. This joint provides a good and cheap method of accomplishing its purpose.

The scarf joint (figs. 3, 4 and 5) is used for lengthening beams, and is made by cutting and notching the ends of timbers and lapping and fitting and bolting through. This method cuts into the timber, but is very strong and neat; in addition for extra strong work an iron fish-plate is used as in the fished joint.

The ends of floor joints and rafters are usually notched (fig. 6) over plates to obtain a good bearing and bring them to the required levels. Where one timber crosses another as in purlins, rafters, wood floor girders, plates, &c, both timbers are notched so as to fit over each other; this cogging (fig. 7) serves instead of fastenings. The timbers are held together with a spike. In this way they are not weakened, and the joint is a very good one for keeping them in position.

|

|

| Fig. 9.—Housing. | Fig. 10.—Halving. |

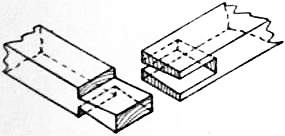

Dovetailing (fig. 8) is used for connecting angles of timber together, such as lantern curbs or linings, and is the strongest form. When an end of timber is let entirely into another timber it is said to be housed (fig. 9). Where timbers cross one another and require to be flush on one or both faces, sinkings are cut in each so as to fit over each other (halving); these can either be square (fig. 10), bevelled (fig. 11) or dovetailed sinkings (fig. 12). The end of one piece of timber cut so as to leave a third of the thickness forms a tenon, and the piece of timber which is to be joined to it has a mortice or slot cut through it to receive the tenon; the two are then wedged or pinned with wood pins (fig. 13).

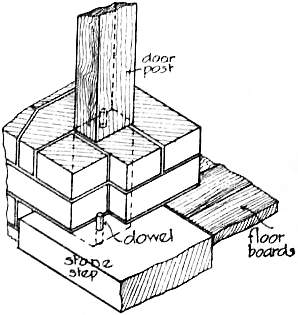

A stub tenon or joggle (fig. 14) is used for fixing a post to a sill; a sinking is cut in the sill and a tenon is cut on the foot of the post to fit into the sinking to keep the post from sliding.

The purpose of a dovetailed tenon (fig. 15) is to hold two pieces of wood together with mortice and tenon so that it can be