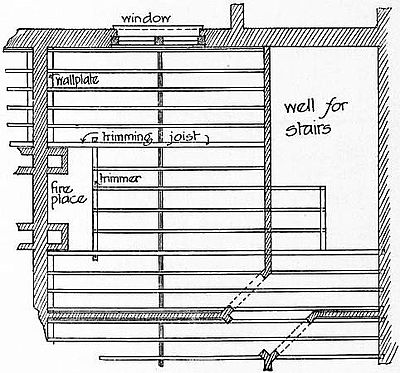

taken apart when necessary. The tenon is cut dovetail shape, and a long mortice permits the wide part of the tenon to go through, and it is secured with wood wedges. Where the floor joists or rafters are trimmed round fires, wells, &c., the tusk tenon joint (fig. 16) is used for securing the trimmer joist. It is formed by cutting a tenon on the trimmer joist and passing it through the side of the trimming joist and fixing it with a wood key. Where large timbers are tusk tenoned together, the tenons do not pass right through, but are cut in about 4 in. and spiked.

A bridle joint or birdsmouth (fig. 17) is formed by cutting one end of timber either V shape or segmental, and morticing the centre of this shaped end. Similar sinkings are cut on the adjoining timber to fit one into the other; these are secured with pins and also various other forms of fastenings.

Fig. 20.—Method of supporting Centering for Concrete. Foxtail wedging (fig. 18) is a method very similar to mortice and tenon. But the tenon does not go through the full thickness of the timber; and also on the end of the tenon are inserted two wedges, so that when the tenon is driven home the wedges split it and wedge tightly into the mortice. This joint is used mostly in joinery. The mitre is a universal joint, used for connecting angles of timber as in the case of picture frames. Built-up joints involve a system of lapping and bolting and fishing, as in the case of temporary structures, for large spans of centering for arches, and for derrick cranes. Dowels are usually 3 or 4 in. long and driven into a circular hole in the foot of a door frame or post; the other end is let into a hole in the sill (fig. 19).

Centering.—Centering is temporary timber or framing erected so as to carry concrete floors or arches of brick or stone, &c.; when the work has set the centering is removed gradually. The centering for concrete floors is usually composed of scaffold boards resting on wood bearers (fig 20). One wood bearer rests along on top of the steel joists; through this bearer long bolts are suspended, and to the bottom of these bolts a second bearer is fixed, and on the bottom bearer the scaffold boards rest. Another method, not much used now, is to fit the boards to the size of the floor and prop them up on legs, but among other disadvantages this process takes up much space and is more costly.

Turning piece is a name given to centering required for turning an arch over (fig. 21); it is only 412 in. wide on the soffit or bed, and is generally cut out of a piece of 3 or 4 in. stuff, the top edge being made circular to the shape of the arch. It is kept in position whilst the arch is setting with struts from ground or sills and is nailed to the reveals, a couple of cross traces being wedged between. In the case of a semicircular or elliptical arch with 412 in. soffit this turning piece would be constructed of ribs cut out of 4 in. stuff with ties and braces. Or the ribs could be cut out of 1 in. stuff, in which case there must be one set of ribs outside and one inside secured with ties and braces; each set of ribs when formed of thin stuff is made of two thicknesses nailed together so as to lap the joints. For spans up to 15 ft. the thin ribs would be used, and for spans above 15 ft. ribs out of 4 in. stuff and upwards. For arches with 9 in. soffit and upwards, whether segmental or semicircular or elliptical, the centres are formed with the thin ribs and laggings up to 15 ft. span; above 15 ft. with 4 in. ribs and upwards (fig. 22).

The lower member of centres is called the tie, and is fixed so as to tie the extremities together and to keep the centre from spreading. Where the span is great, these ties, instead of being fixed straight, are given a rise so as to allow for access or traffic underneath. Braces are necessary to support the ribs from buckling in, and must be strong enough and so arranged as to withstand all stresses. Laggings are small pieces or strips of wood nailed on the ribs to form the surface on which to build the arch, and are spaced 1 in. apart for ordinary arches; for gauged arches they are nailed close together and the joints planed off. When centres are required to be taken down, the wedges upon which the centre rests are first removed so as to allow the arch to take its bearing gradually. Centres for brick sewers and vault arching are formed in the same way as previously mentioned, with ribs and laggings, but the thickness of the timbers depends upon the weight to be carried.

Floors.—For ordinary residential purposes floors are chiefly constructed of timber. Up to about the year 1895 nearly every modern building was constructed with wood joists, but because of evidence adduced by fire brigade experts and the serious fires that have occurred fire-resisting floors have been introduced. These consist of steel girders and joists, filled in with concrete or various patented brick materials in accordance with such by-laws as those passed by the London County Council and other authorities. The majority of the floors of public